curling device

A crimping device and crimping technology, used in textiles and papermaking, etc., can solve problems such as entanglement of filler wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

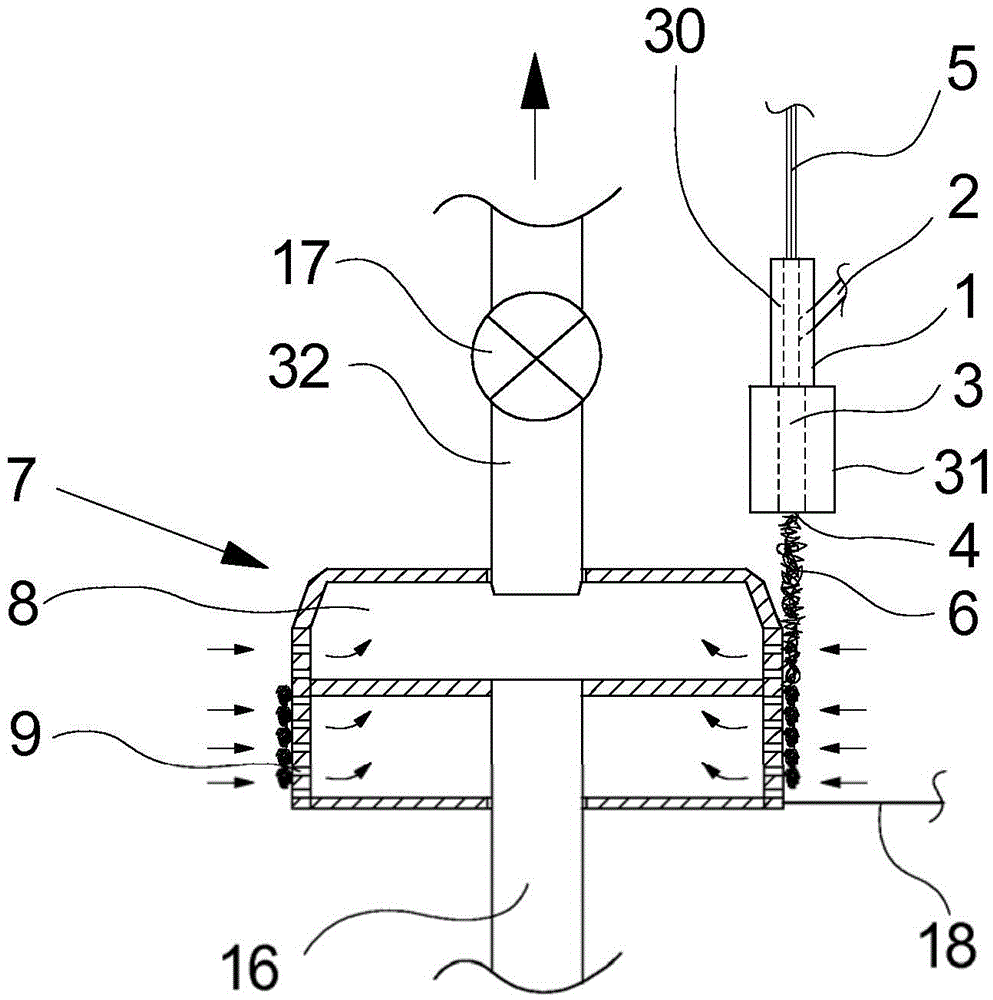

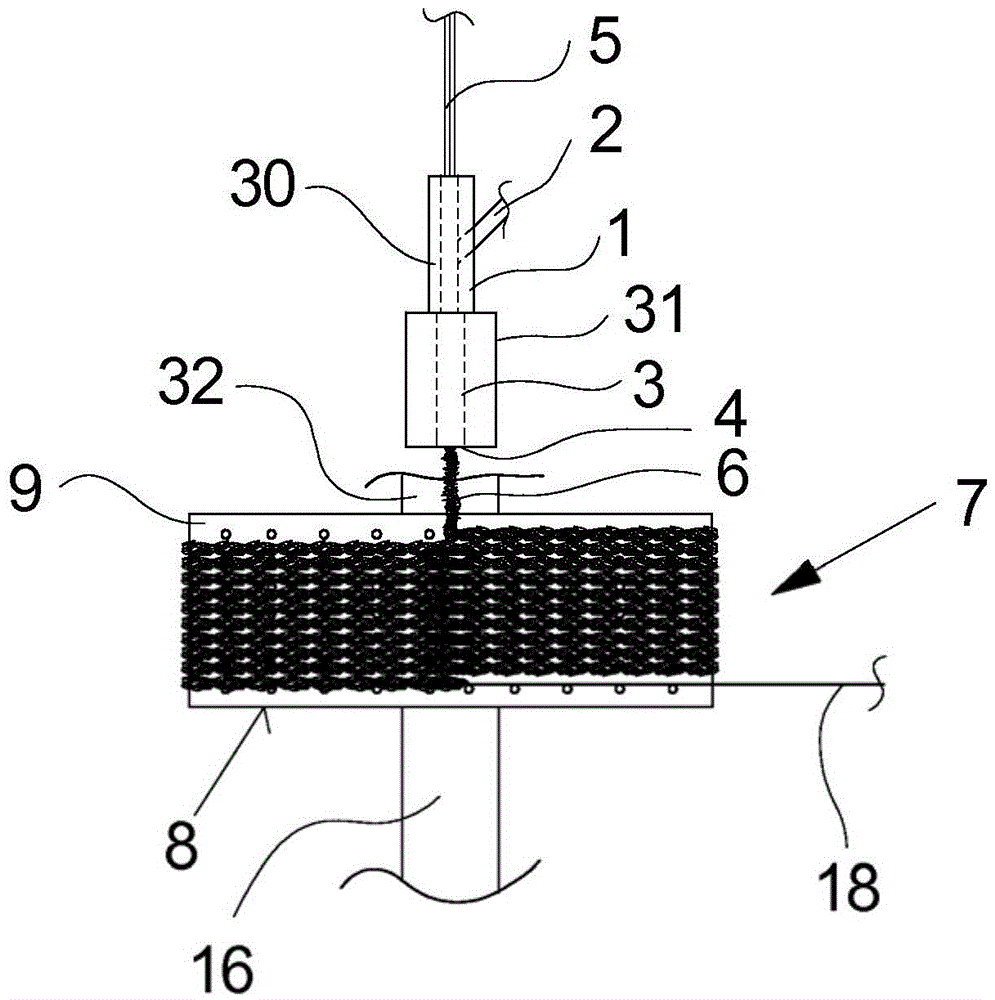

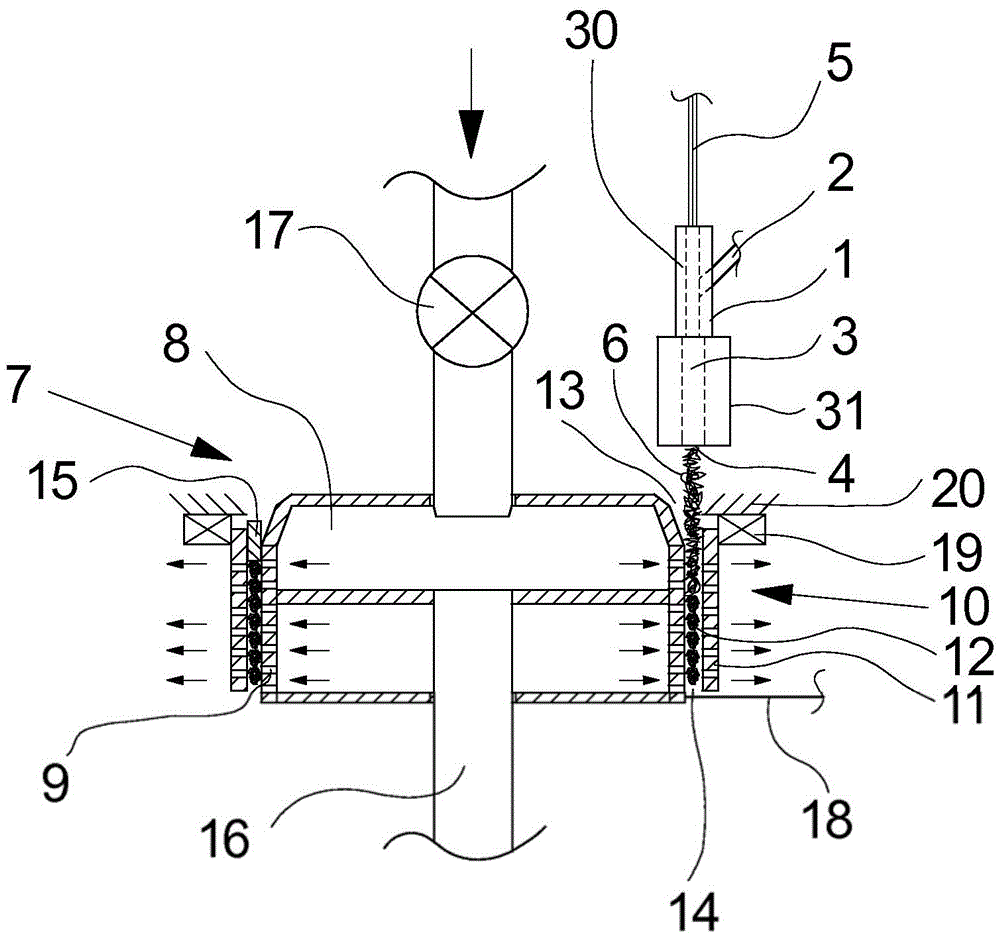

[0024] exist figure 1 and figure 2 In , a first embodiment is schematically shown in several views. Both illustrations show the embodiment in action. in figure 1 shows a partial cross-section of the entire device and figure 2 A side view is shown. The following description applies to both figures unless it is specifically indicated which figure is referred to.

[0025] according to figure 1 and 2 The embodiment of the present invention has a conveyor nozzle 1 coupled via a fluid connection 2 to a fluid source (not shown here). Conveyor nozzle 1 comprises a continuous guide channel 30 which in figure 1 and 2 shown in dotted line. The guide channel 30 penetrates the conveyor nozzle 1 and thus forms an inlet at the upper end. The lower end of the guide channel 30 of the conveyor nozzle 1 opens into the stuffer box 3 . The stuffer box 3 is in figure 1 and 2 is likewise shown in dashed lines and is constructed in the housing 31 . The housing 31 has a thread plug ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com