Process for preparing cured epoxy composites

A composite material, curing heat technology, used in conductive coatings, devices that apply liquid to surfaces, electrical equipment enclosures / cabinets / drawers, etc., can solve problems such as difficulty in fine-tuning filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

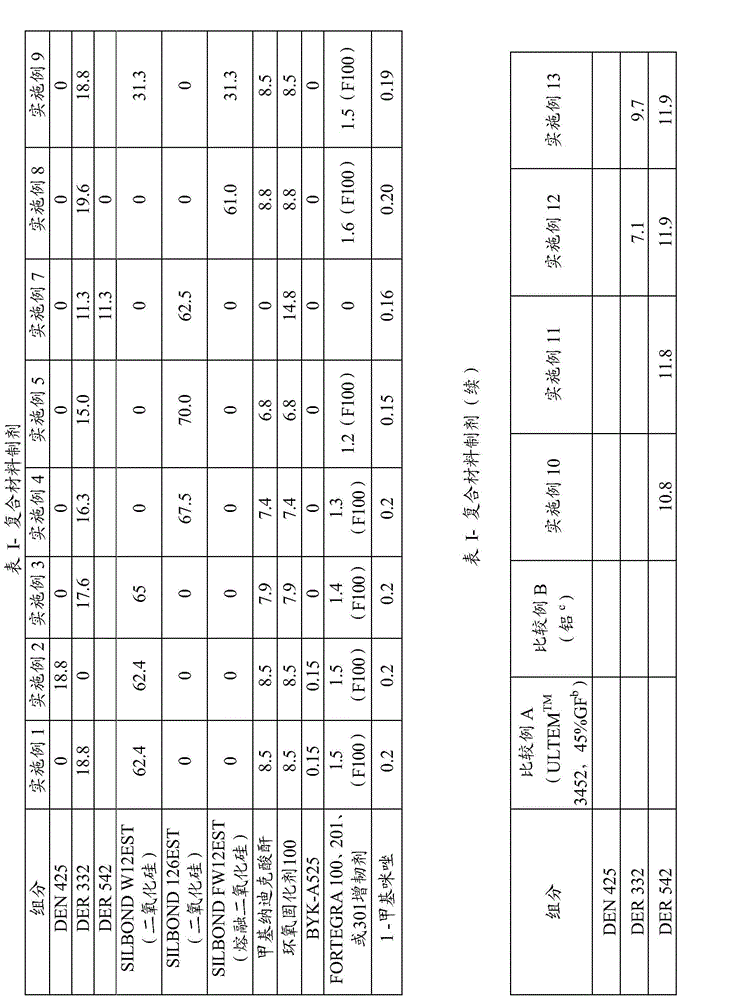

Embodiment 1-18 and comparative example A and B

[0160] Examples and comparative examples of epoxy composite compositions of the present invention are shown in Tables I-III. The mixing, casting and curing process of the epoxy composite composition is generally carried out as follows.

[0161] General procedure

[0162] The required amount of filler was dried overnight in a vacuum oven at a temperature of about (~) 70°C. Usually contains FORTEGRA TM Epoxy resins with toughener and anhydride hardener were individually pre-warmed to ~60°C. A wide mouth plastic container is filled with the specified amount by weight of warmed epoxy resin, warmed anhydride hardener, optional BYK-A 525 and / or BYK W9010 and 1-methylimidazole, which is added to Manually swirl in warm filler that may contain FR additives before. The contents of the container are then placed in the FlackTek SpeedMixer TM Mixing was performed using multiple cycles from about 800 to about 2000 rpm, duration -1-2 minutes.

[0163] The mixed formulations were fill...

Embodiment 19

[0174] In this Example 19, the formulation of the invention (the formulation of Example 1) was cured to form an epoxy composite which was then plated with a copper layer according to the general plating procedure and as described in Table IV below:

[0175] General Plating Procedure

[0176] Processes for plating the epoxy composite substrates of the present invention may include various techniques for rendering the surface receptive to metallization. In general, epoxy substrates can be metallized by a process that first involves sequential exposure to a material containing the composition, increased attack in a subsequent etch step, followed by exposure to an etch step followed by exposure to substantially remove Residues from the etching step.

[0177]The first step, often referred to as "solvent swelling," utilizes a "swelling agent" that may include materials such as solvents and / or basic materials such as alkali metal hydroxides. The second step, often referred to as ...

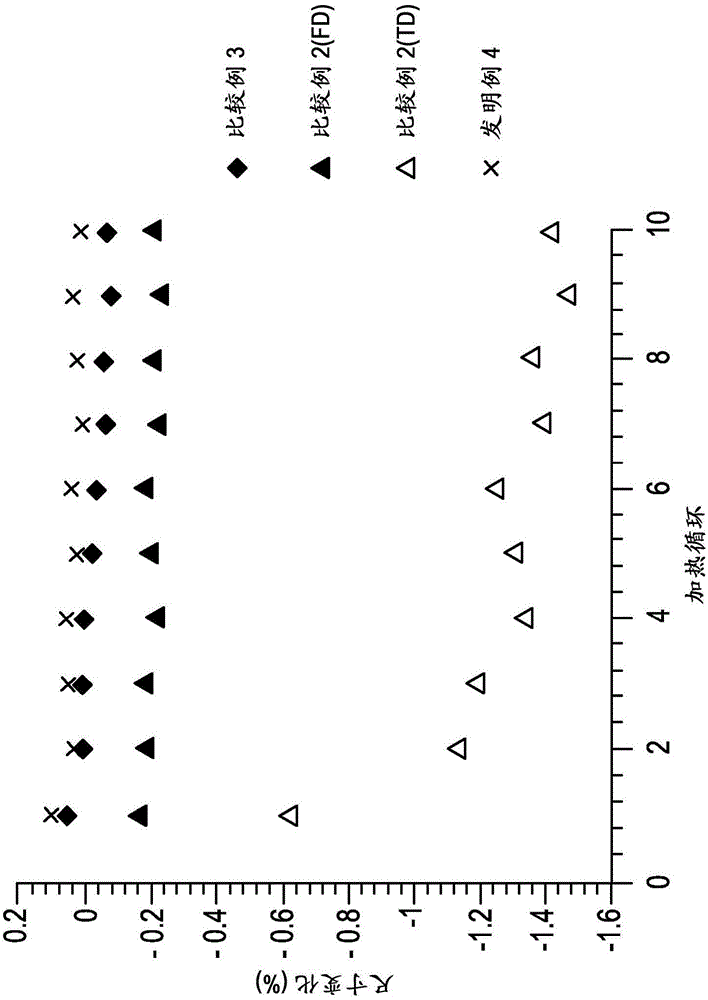

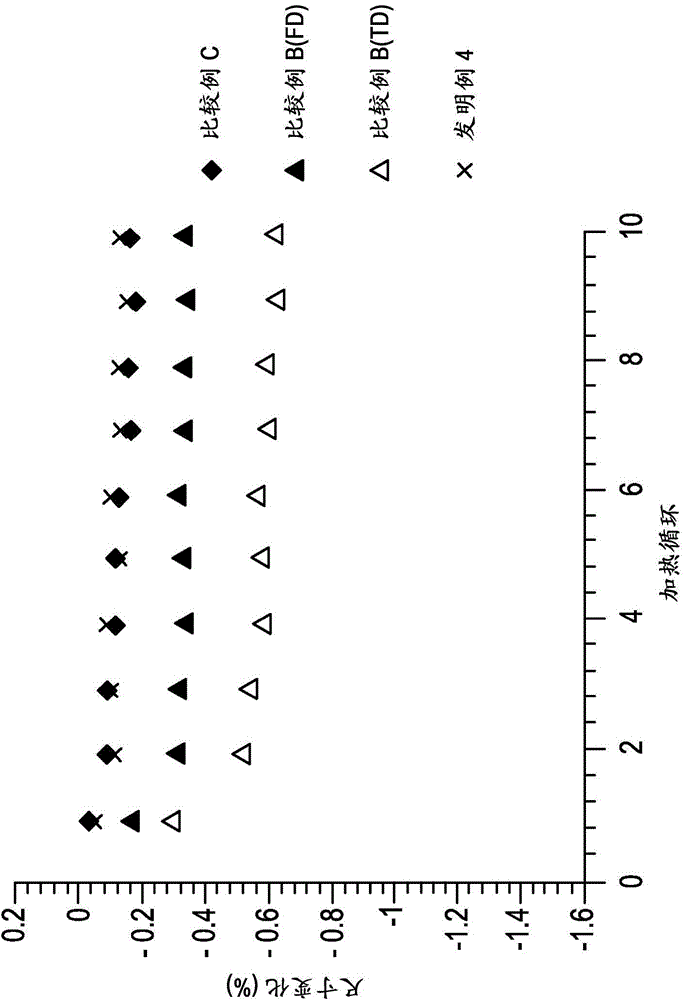

Embodiment 20 and comparative example C

[0190] RF Filter Sample Fabrication and Testing Procedures

[0191] Two RF filter cartridge samples (Example 20 and Comparative Example C) were prepared as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com