Lithium sulfur battery adopting stannous sulfide as anchoring center and preparation method of positive electrode of lithium sulfur battery

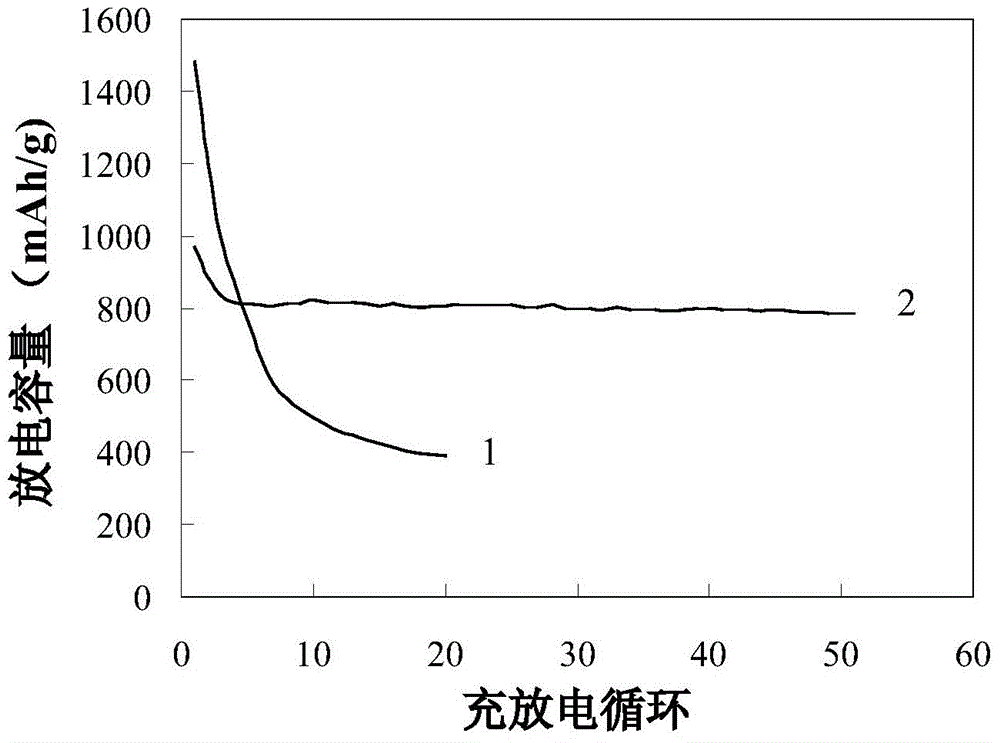

A stannous sulfide and lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, batteries, etc., can solve the problems of capacity loss, lithium-sulfur battery capacity decline, poor cycle life, etc., to improve speed capacity, good electrode reaction reversible The effect of stability and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of macroporous carbon material supported by nano-stannous sulfide

[0032] Weigh commercially available hydrophilic nano-CaCO with a particle size of 15-40 nm according to the mass ratio of 1:1:0.1 3 (10g), glucose (10g) and stannous chloride (1g), added to 100mL deionized water, ultrasonic vibration (ultrasonic frequency 40kHz) mixed for 30 minutes to dissolve glucose and stannous chloride and mix with nano-CaCO 3 Disperse evenly; heat to evaporate water, and then solidify at 160°C for 6 hours; heat the cured product to 700°C under the protection of a nitrogen atmosphere, and carbonize at a constant temperature for 2 hours; cool to 500°C, pass in hydrogen sulfide gas, and react for 1 hour. The product was washed and filtered successively with 1 wt% hydrochloric acid and deionized water, and then dried at a constant temperature at 120° C. for 4 hours to obtain a macroporous carbon material containing diffusely distributed nano-stannous sulfide on ...

Embodiment 2

[0033] Example 2: Carrying sulfur in macroporous carbon

[0034] Weigh commercially available hydrophilic nano-CaCO with a particle size of 15-40 nm according to the mass ratio of 1:1:0.3 3 (10g), sucrose (10g) and stannous nitrate (3g), added to 100mL deionized water, ultrasonic vibration (ultrasonic frequency 40kHz) mixed for 30 minutes to dissolve sucrose and stannous nitrate and mix with nano-CaCO 3 Disperse evenly; heat to evaporate the water, and then solidify at 160°C for 6 hours; heat the cured product to 850°C under the protection of nitrogen atmosphere, and carbonize at constant temperature for 2 hours; cool to 500°C, pass in hydrogen sulfide gas, and react for 1 hour. The product was washed and filtered successively with 1 wt% hydrochloric acid and deionized water, and then dried at a constant temperature at 120° C. for 4 hours to obtain a macroporous carbon material containing diffusely distributed nano-stannous sulfide on the inner wall.

[0035] Grind and mix el...

Embodiment 3

[0036] Embodiment three: stannous sulfide coating

[0037] Weigh commercially available hydrophilic nano-CaCO with a particle size of 15-40 nm according to the mass ratio of 1:1:0.5 3 (10g), starch (10g) and stannous sulfate (5g), added to 100mL deionized water, ultrasonic vibration mixing (ultrasonic frequency 40kHz) for 30 minutes to dissolve starch and stannous sulfate and mix with nano-CaCO 3 Disperse evenly; heat to evaporate the water, and then solidify at 160°C for 6 hours; heat the cured product to 900°C under the protection of nitrogen atmosphere, and carbonize at constant temperature for 2 hours; cool to 500°C, pass in hydrogen sulfide gas, and react for 1 hour. The product was washed and filtered successively with 1 wt% hydrochloric acid and deionized water, and then dried at a constant temperature at 120° C. for 4 hours to obtain a macroporous carbon material containing diffusely distributed nano-stannous sulfide on the inner wall.

[0038] Grind and mix elemental...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com