A preparation method of graphene-coated silicon dioxide nanotube composite negative electrode material for lithium ion battery

A graphene-coated, nanotube composite technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as limiting silica anode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

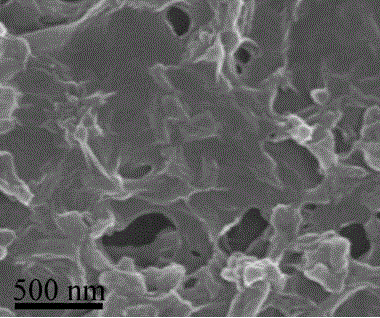

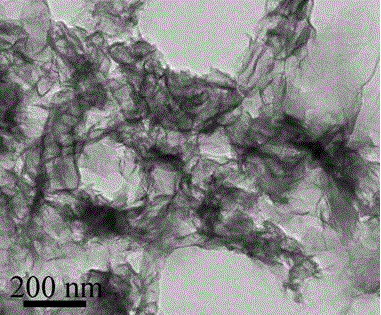

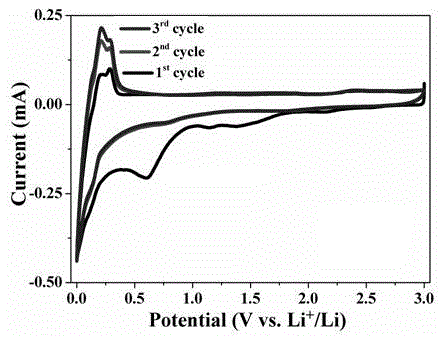

Image

Examples

Embodiment 1

[0026] A preparation method of a graphene-coated silicon dioxide nanotube composite negative electrode material for a lithium ion battery, the steps are as follows:

[0027] (1) Disperse 0.1 gram of zinc oxide nanorods in 120 milliliters of ethanol solution, then add 20 milliliters of water, 20 milliliters of ammonia and 60 microliters of ethyl orthosilicate solution successively, react at room temperature for 1 hour, wash and dry the product, Obtain zinc oxide / silica core-shell nanorods;

[0028] (2) Disperse 0.6 gram of the product obtained in step (1) into 60 milliliters of 0.5 mol / liter sodium chloride aqueous solution, add 0.15 gram of positively charged polydiallyl dimethyl ammonium chloride, stir for 1 hour , the product is washed and dried to obtain zinc oxide / silica core-shell nanorods modified by polydiallyldimethylammonium chloride;

[0029] (3) Disperse 0.6 gram of the product obtained in step (2) and 0.2 gram of graphene oxide into 50 milliliters of aqueous solut...

Embodiment 2

[0033] A preparation method of a graphene-coated silicon dioxide nanotube composite negative electrode material for a lithium ion battery, the steps are as follows:

[0034] (1) Disperse 0.01 gram of zinc oxide nanorods in 1000 milliliters of ethanol solution, then add 100 milliliters of water, 100 milliliters of ammonia and 50 microliters of tetraethyl orthosilicate solution successively, react at room temperature for 0.5 hours, wash and dry the product, Obtain zinc oxide / silica core-shell nanorods;

[0035] (2) Disperse 0.06 gram of the product obtained in step (1) into 20 milliliters of 0.5 mol / liter sodium chloride aqueous solution, add 0.6 gram of positively charged polydiallyldimethylammonium chloride, and stir for 24 hours , the product is washed and dried to obtain zinc oxide / silica core-shell nanorods modified by polydiallyldimethylammonium chloride;

[0036](3) Disperse 0.06 gram of the product obtained in step (2) and 0.3 gram of graphene oxide into 50 milliliters ...

Embodiment 3

[0039] A preparation method of a graphene-coated silicon dioxide nanotube composite negative electrode material for a lithium ion battery, the steps are as follows:

[0040] (1) Disperse 0.01 gram of zinc oxide nanorods in 120 milliliters of ethanol solution, then add 35 milliliters of water, 35 milliliters of ammonia and 30 microliters of tetraethyl orthosilicate solution successively, react at room temperature for 4 hours, wash and dry the product, Obtain zinc oxide / silica core-shell nanorods;

[0041] (2) Disperse 0.06 gram of the product obtained in step (1) into 200 milliliters of 0.5 mol / liter sodium chloride aqueous solution, add 0.06 gram of positively charged polydiallyldimethylammonium chloride, and stir for 12 hours , the product is washed and dried to obtain zinc oxide / silica core-shell nanorods modified by polydiallyldimethylammonium chloride;

[0042] (3) Disperse 0.06 gram of the product obtained in step (2) and 0.06 gram of graphene oxide into 50 milliliters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com