Substrate processing control equipment and control method

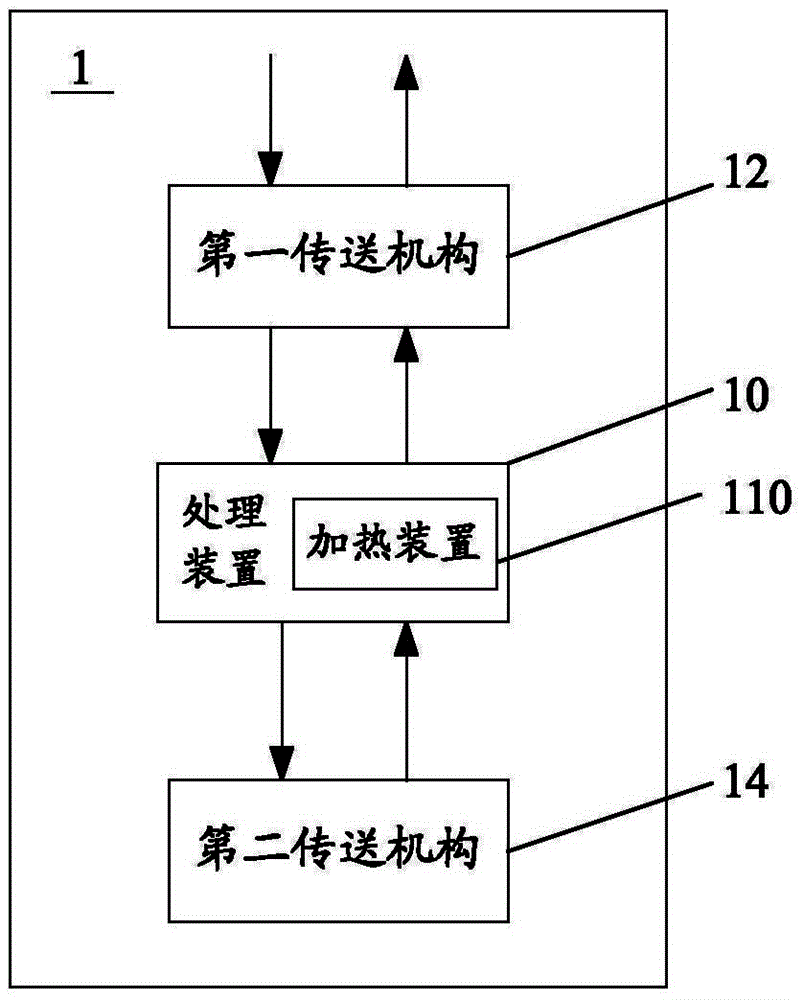

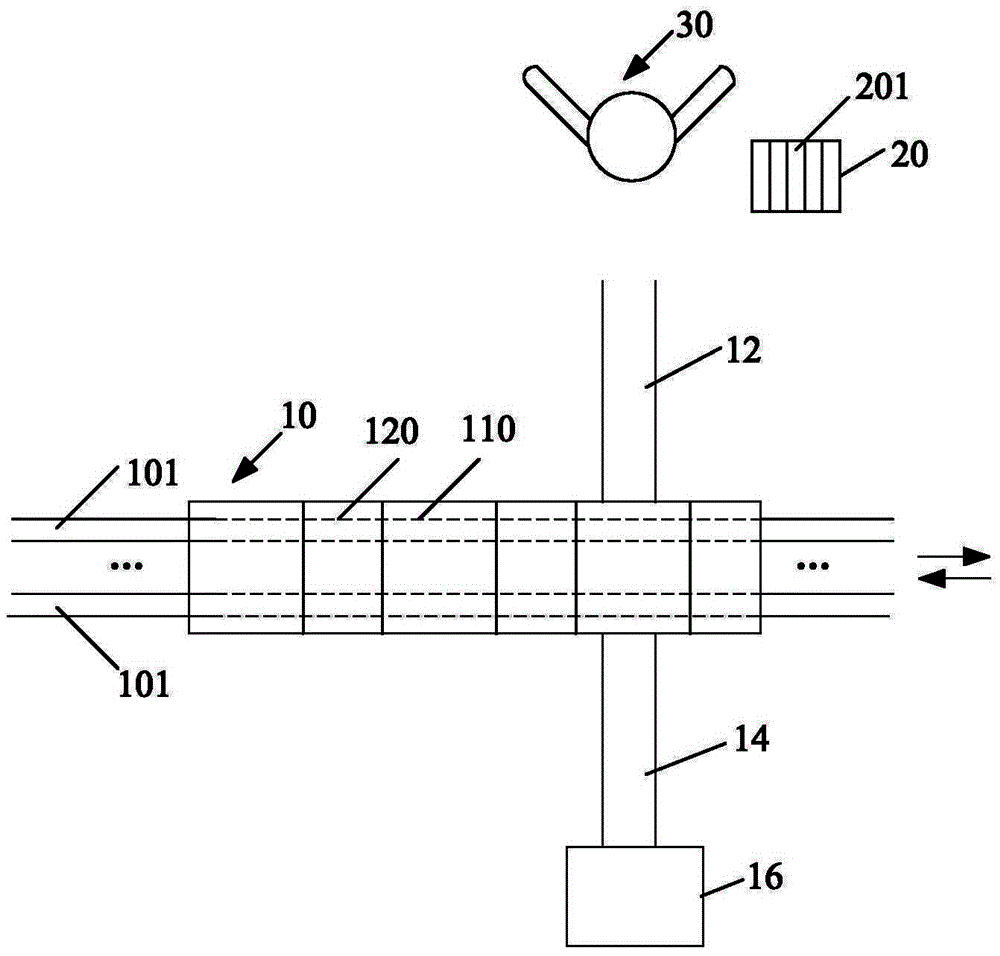

A technology for controlling equipment and substrate processing, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., and can solve the problems of long waiting time and low work efficiency of substrate groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

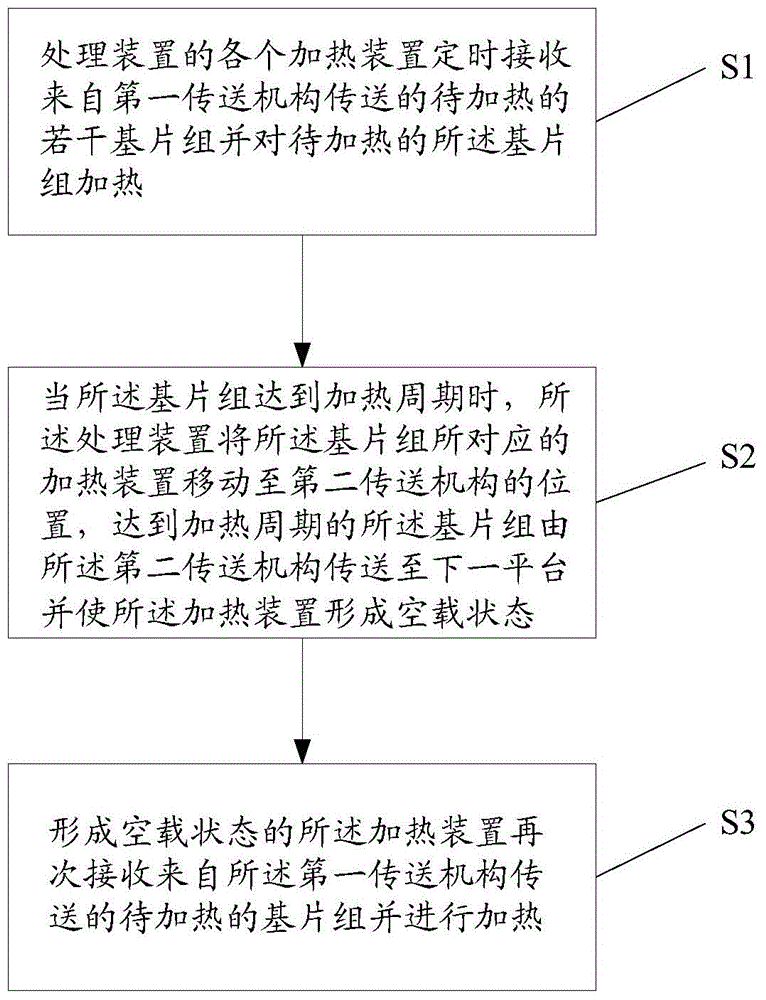

[0035] Please refer to image 3 , the first embodiment of the control method for substrate processing of the present invention includes:

[0036] Step 1 S1: Each heating device 110 of the processing device 10 regularly receives the substrate group 20 to be heated from the first conveying mechanism 12 and heats the substrate group 20 to be heated;

[0037] Step 2 S2: When the substrate group 20 reaches the heating cycle, the processing device 10 moves the heating device 110 corresponding to the substrate group 20 to the position of the second conveying mechanism 14, and the substrate group 20 that reaches the heating cycle Transfer to the next platform by the second transfer mechanism 14 and make the heating device 110 into an empty state;

[0038] Step 3 S3: The heating device 110 in an empty state receives and heats the substrate group 20 to be heated transported from the first transport mechanism 12 again.

[0039]The substrate processing control method of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com