Device and method for rapidly separating sea buckthorn fruit seeds

A seabuckthorn fruit, fast technology, applied in solid separation, chemical instruments and methods, separation of solids from solids by air flow, etc., can solve problems such as low separation efficiency and environmental pollution, and achieve high separation efficiency and low residual rate. ,Easy to clean the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

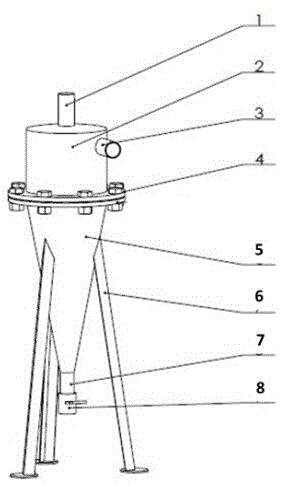

[0018] Pass the fresh sea buckthorn pomace after squeezing the juice through a trommel to remove the stalks above 2 cm. Collect the destemmed pomace, collect the destemmed pomace for the cellulase hydrolysis test, the enzymatic hydrolysis conditions are: 1% cellulase added, pH adjusted to 5.0, enzymatic hydrolysis temperature controlled at 40 ℃, enzyme The solution time is 1.5 hours. After enzymolysis, mix evenly at a ratio of material to water (mass: volume) of 1:30, and adjust the temperature of the material to 33°C. Feed the uniformly mixed materials into the bucket screw pump, turn on the power, pump into the device for separating seabuckthorn fruit seeds, and adjust the opening degree of the ball valve 8 of the underflow port 7 to 30 degrees. The mixed materials are fed into a bucket screw pump, and then pumped into the device for separating sea buckthorn fruit seeds after the power is turned on; the sea buckthorn fruit seeds are separated by hydraulic power. Due to the d...

Embodiment 2

[0020] The difference from Example 1 is that the enzymatic hydrolysis conditions are: 1.5% cellulase addition, enzymatic hydrolysis pH 5.5, enzymatic hydrolysis temperature controlled at 50° C., enzymatic hydrolysis time 2 hours. Adjust the material liquid temperature to 25°C, and other conditions are the same. Feed the uniformly mixed materials into the bucket screw pump, turn on the power, pump into the device for separating seabuckthorn fruit seeds, and adjust the opening degree of the lower overflow ball valve to 60 degrees. After separation, it was determined that the purity of underflow fruit seeds was 90.0%, and the residual rate of overflow fruit seeds was 8.7%.

Embodiment 3

[0022] The difference from Example 2 is that the enzymolysis conditions are: 2% cellulase addition, enzymolysis time is 2h, enzymolysis temperature is controlled at 45°C, enzymolysis time is 1.5 hours. After enzymolysis, mix evenly at the ratio of material to water (mass:volume) 1:40, and adjust the temperature of the material to 40℃, and other conditions are the same. Feed the uniformly mixed materials into the bucket screw pump, turn on the power, pump into the device for separating seabuckthorn fruit seeds, and adjust the opening degree of the lower overflow ball valve to 45 degrees. After separation, it was determined that the purity of the underflow fruit seeds was 94.6%, and the residual rate of the overflow fruit seeds was 2.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com