Tin ingot brand character code mechanical automatic printer

A printer and printing mechanism technology, applied in the field of tin metallurgy, can solve problems such as irregular layout, low production efficiency, and low printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

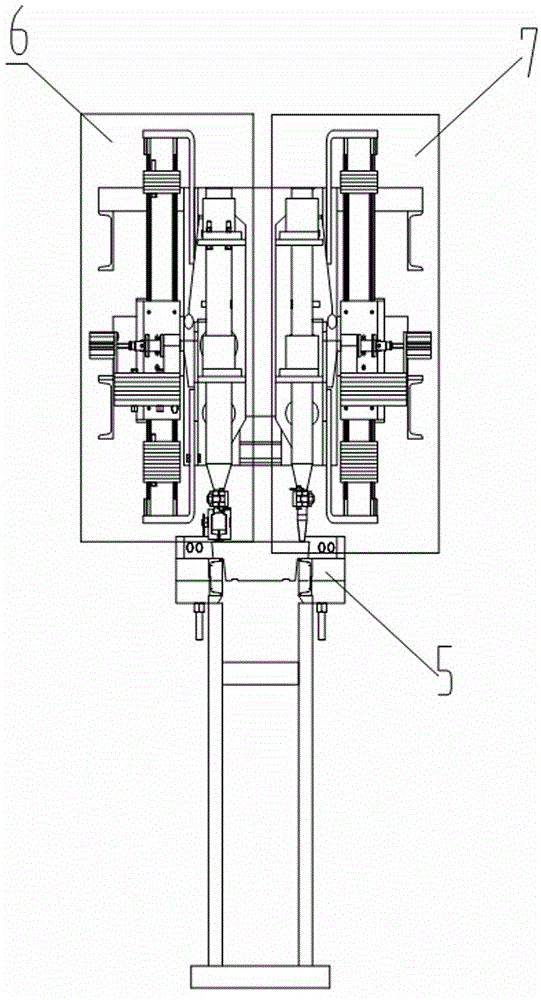

[0019] A tin ingot trademark code mechanical automatic printer, including a tin ingot conveyor 1, a tin ingot pusher 2, a tin ingot printer 3, a tin ingot stacker 4, and a rail anvil 5, the tin ingot printer 3 includes a code printing Mechanism, the character code printing mechanism includes a double-line character code single-group mechanism 6 and a single-line character code single-group mechanism 7, and the double-line character code single-group mechanism 6 includes a word clip character code 61, a quick-release flange 62, a hammer guide cylinder Seat 63, fin rod hammer 64, lifting fin rod hammer group structure 66 and main guide cylinder base 67; hammer guide cylinder base 63 and main guide cylinder base 67 are arranged on the frame 65, and fin rod hammer 64 passes through hammer guide cylinder base 63 and the main guide tube seat 67, the lower end of the fin rod hammer 64 is provided with a clip character code 61, the clip character code 61 and the fin rod hammer 64 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com