Rear part visualization detection apparatus for wearing of shield machine cutter and method thereof

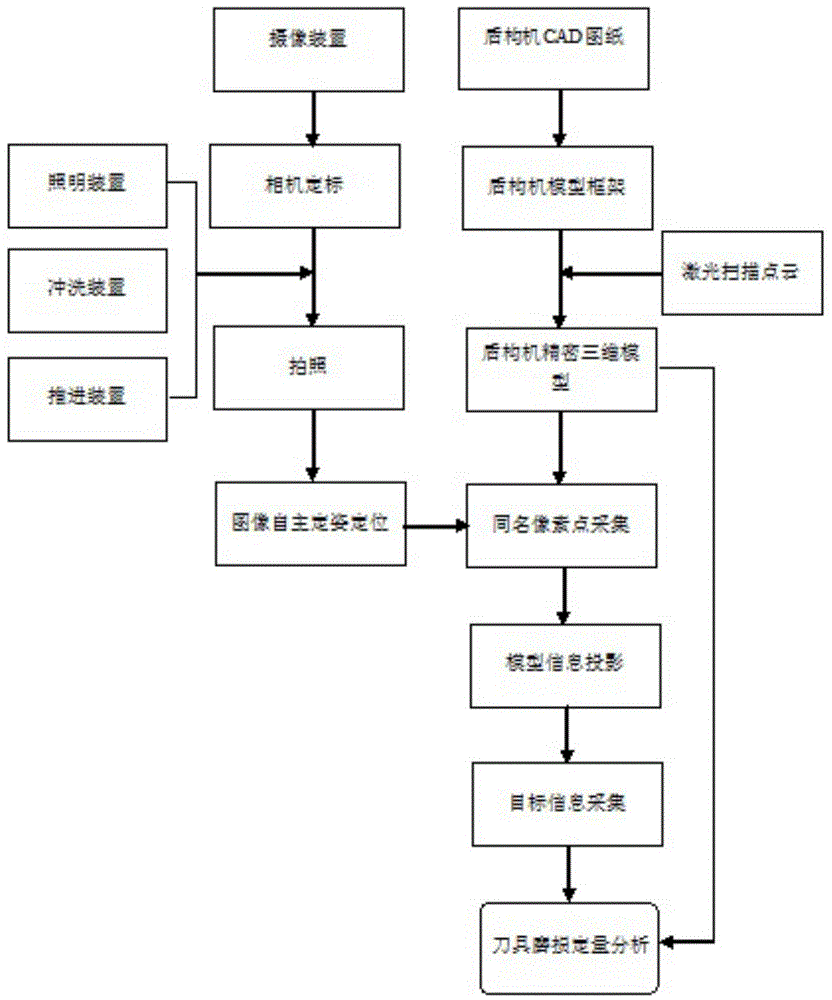

A shield machine tool and detection device technology, which is applied in the direction of measuring devices, optical devices, and material analysis through optical means, can solve the problem of inability to accurately predict tool wear, inability to detect eccentric wear and abnormal wear, and affecting tunnels. The safety of surrounding buildings and other issues can be achieved to maximize construction and operation benefits, reduce project safety risks, and achieve important economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

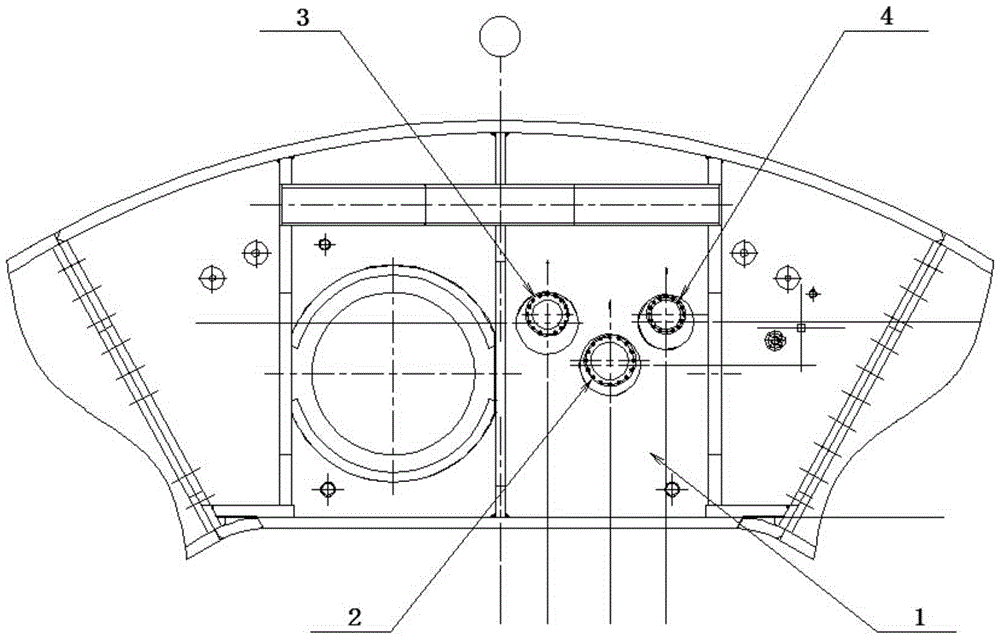

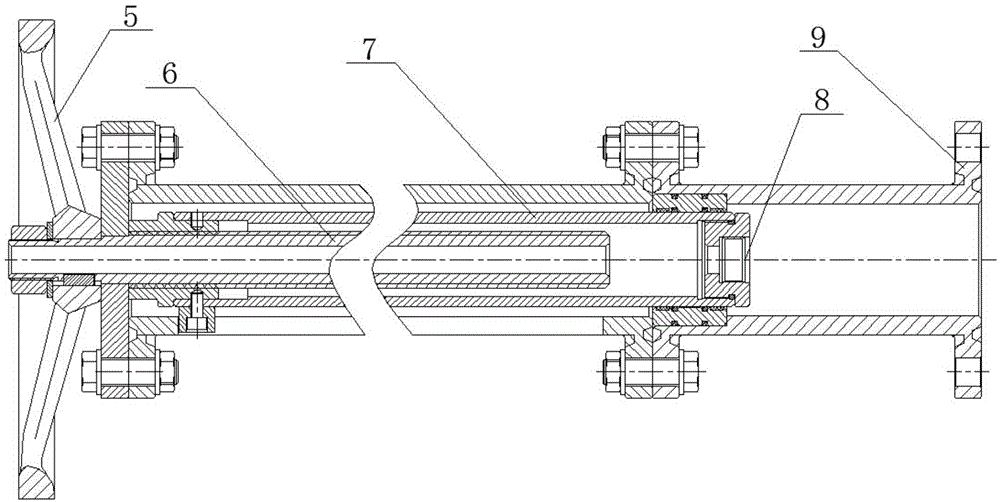

[0027] like figure 2 In the described embodiment, a rear visual detection device for shield machine tool wear includes a camera device 2, an illumination device 3, a flushing device 4, a first propulsion device, a second propulsion device, a data acquisition and analysis device and The bubble chamber 1 of the shield machine. There are three round holes on the front wall of the bubble chamber 1 of the shield machine. The round holes are welded with ball joints and ball valves are respectively installed for connecting the camera device 2, the lighting device 3 and the washing device 4. The first propulsion The device is respectively threaded with the camera device 2 and the lighting device 3, the second propulsion device is threaded with the flushing device 4, the camera device 2 is connected with the data acquisition and analysis device, and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com