Preparation method for nanoscale base material of crude oil pourpoint depressant

A crude oil pour point depressant, nano-scale technology, applied in the analysis of materials, mechanical equipment, particles and sedimentation analysis, etc., can solve the problems of high wax content, poor fluidity, high consumption of fuel oil and power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

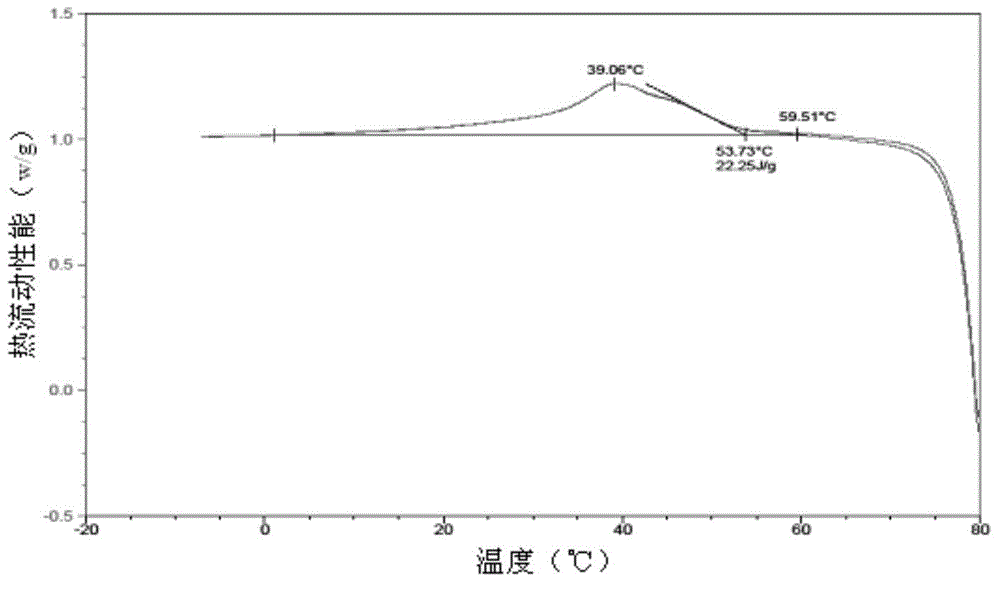

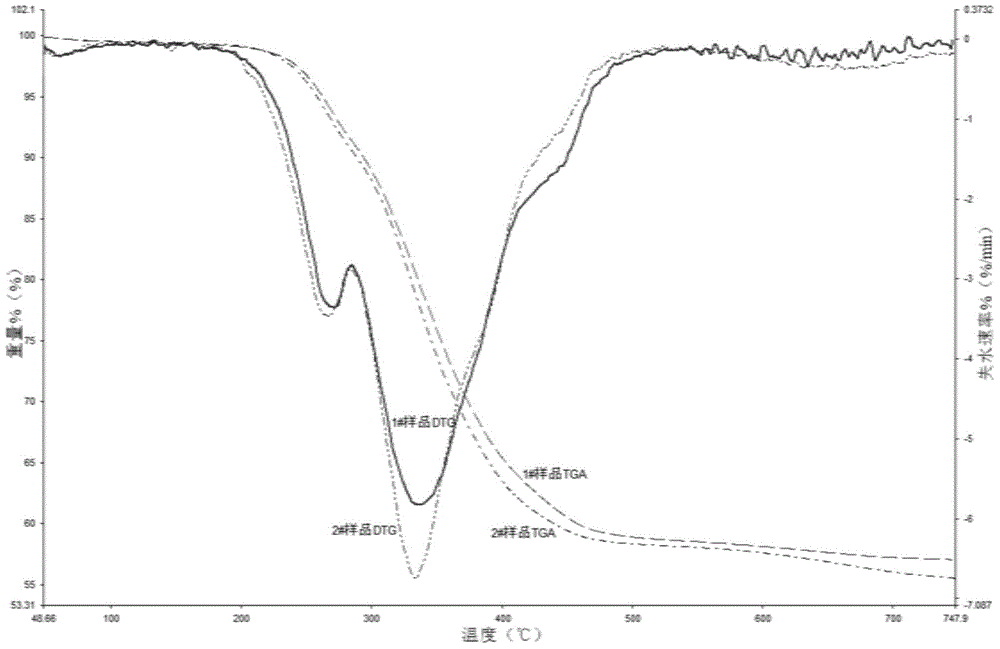

[0030] The preparation method of the crude oil point depressant nano-scale substrate provided by the present invention comprises the following steps: thermal weight loss test, crystallization performance test, X-ray diffraction test, powder particle size test, moisture content test and the nano-scale base material of the crude oil point depressant The viscosity test of adding the compounding agent formed by the base material to crude oil, wherein the polar group is grafted onto the surface of inorganic nanoparticles, when the thermal weight loss test, crystallization performance test, X-ray diffraction test, When the results of the powder particle size test, the moisture content test and the viscosity test of adding the composite agent formed by the nano-scale base material of the crude oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com