Coal cutter state monitoring method based on black box

A technology of coal shearer and black box, applied in the field of status information monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

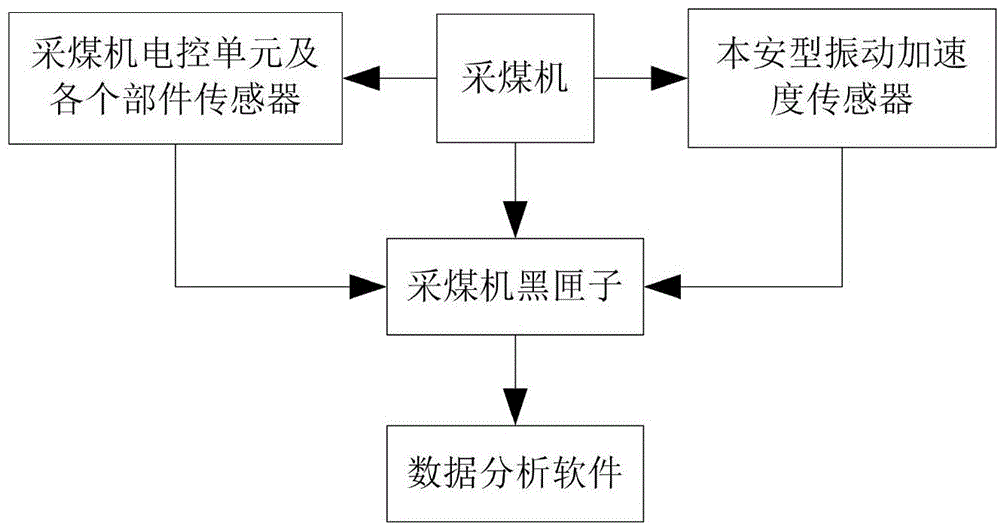

[0080] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings: figure 1 As shown, the shearer condition monitoring system based on the black box mainly includes the black box of the shearer, the intrinsically safe vibration acceleration sensor with a coal safety certificate, the electric control system of the shearer and sensors on various components, and data analysis software. The black box of the coal mining machine adopts the embedded motherboard Intel3945A, the storage medium is a 512G solid-state hard disk, and has RS232 serial port communication and TCP / IP network port communication functions, multi-channel acquisition of vibration acceleration signals, the highest total sampling frequency is 250K (adjustable), 12V / 1.5A power supply, the system mainly includes Windows XP / E main control module, data communication module, vibration signal acquisition module, data storage module. The intrinsically safe vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com