Heating wall body and manufacturing method thereof

A wall and ointment technology, which is applied in the fields of wall insulation, building materials, and winter heating, can solve the problems of heat loss, bursting, and low insulation effect, and achieve the effects of reduced construction period, less heat loss, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

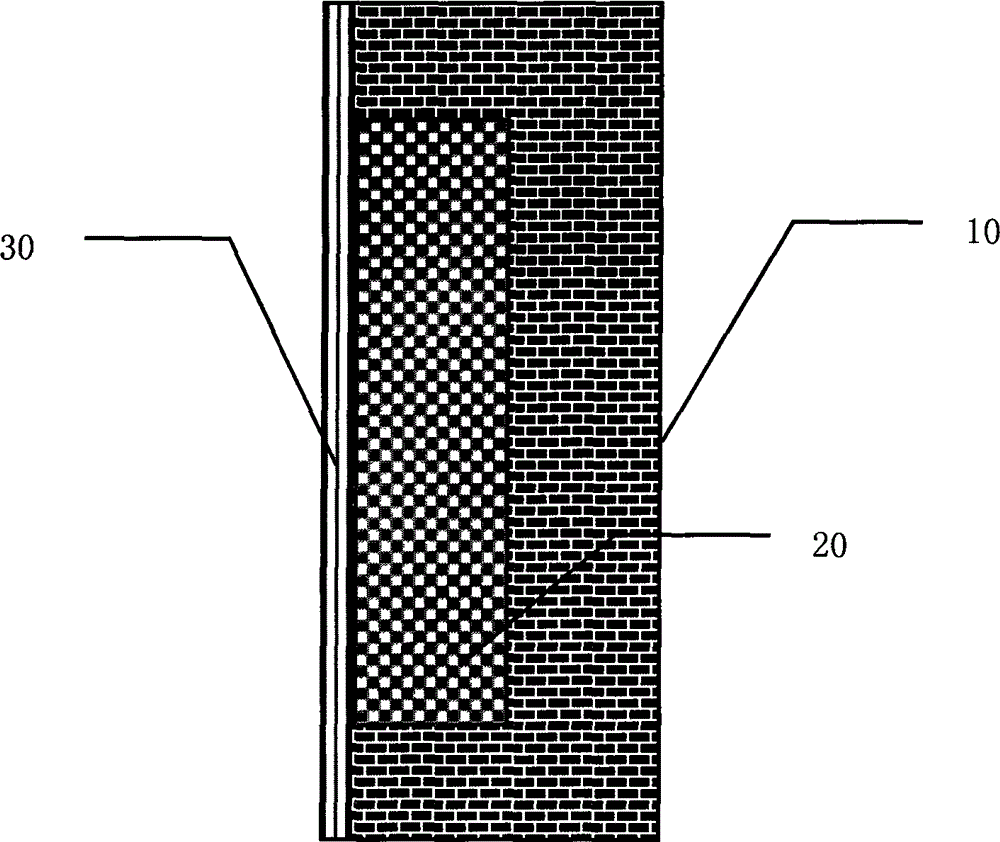

[0025] A heating wall body and a preparation method thereof. It is characterized in that it consists of a glue guide groove in the wall body, a conductive paint ointment and an exterior decorative coating.

[0026] In the heating wall, the glue guide groove is a cuboid structure with a width of 15mm and a depth of 35mm. The inside of the glue guide groove is filled with energized heat-generating paint ointment.

[0027] The conductive paint ointment contains graphene, carbon crystals, and carbon fibers. It generates heat after being energized, and its thermal resistance is 0.1m 2 k / w.

[0028] Its preparation method lies in the following steps:

[0029] 1) Squeeze the conductive paint ointment into the guide groove, flatten it, and connect it to the conductive wire;

[0030] 2) After the ointment is dry and solidified, use cement slurry to smear the convex and concave parts of the wall to make it smooth, and the oil stains on the surface are treated with 15% caustic soda, a...

Embodiment 2

[0038] A heating wall body and a preparation method thereof. It is characterized in that it consists of a glue guide groove in the wall body, a conductive paint ointment and an exterior decorative coating.

[0039] In the heating wall, the glue guide groove is a cuboid structure with a width of 20mm and a depth of 40mm. The inside of the glue guide groove is filled with energized heat-generating paint ointment.

[0040] The conductive paint ointment contains graphene, carbon crystals, and carbon fibers. It generates heat after being energized, and its thermal resistance is 0.1m 2 k / w.

[0041] Its preparation method lies in the following steps:

[0042] 1) Carve a guide groove on the wall to form a conductive circuit;

[0043] 2) Squeeze the conductive paint ointment into the guide groove, flatten it, and connect it to the conductive wire;

[0044] 3) After the ointment is dry and solidified, use cement slurry to smear the convex and concave parts of the wall to make it sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com