Concrete pile construction equipment and method

A technology for concrete piles and construction devices, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of difficulty in forming the design depth of the pile holes, not making full use of the original soil, and unable to carry out the next construction. Fast, wide-ranging, robust results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

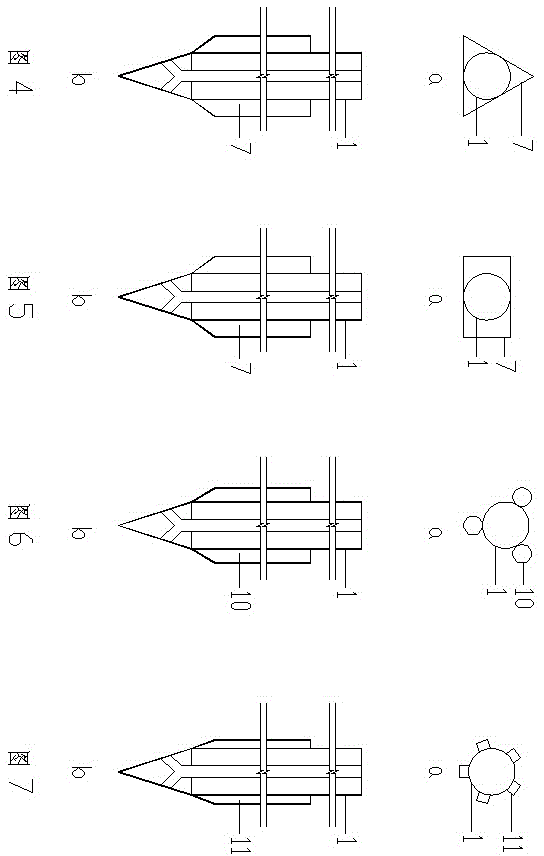

Image

Examples

Embodiment Construction

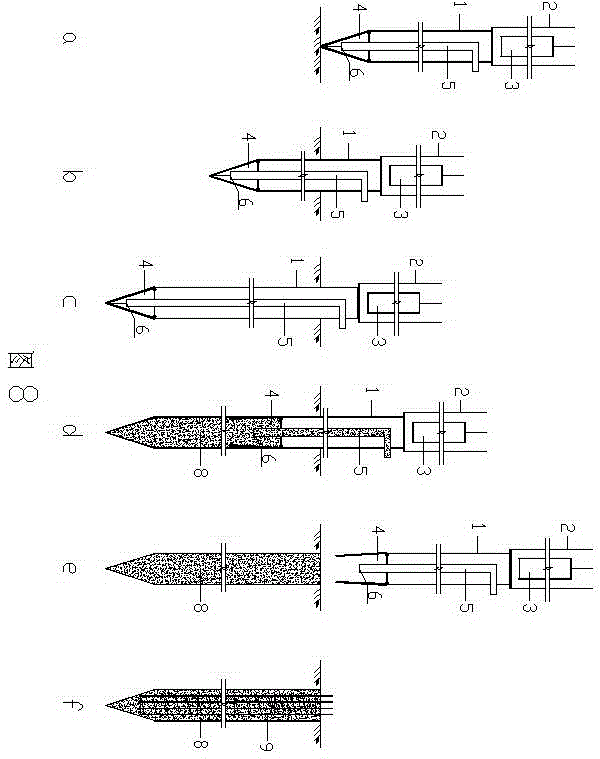

[0057] figure 1 It is the sectional view of an embodiment of the construction device of the concrete pile of the first kind of structural form of the present invention, as figure 1 As shown, the top of the casing 1 is connected and fixed with a ramming sleeve 2, and a ramming hammer that can be lifted is arranged inside the ramming sleeve 2; the bottom end of the casing 1 is connected and fixed with an impact hammer tip 4, and the impact hammer tip 4 consists of four Composed of three triangular steel plates, the upper side of each steel plate is hingedly connected with the bottom end of the casing 1 for easy closing and opening. When the steel plates are closed inward, a hollow cone with a sharp point downward is formed, and an opening is formed when the steel plate is opened outward; The interior of the casing 1 is provided with a delivery pipe 5 capable of transporting concrete. The upper opening of the delivery pipe 5 protrudes out of the casing 1 at the upper end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com