Screw stirring pulp squeezer

A technology of screw press and screw mixing, which is applied in pulp dehydration, pulp fat/resin/pitch/wax removal, raw material separation, etc., to achieve the effect of small footprint, high efficiency and high-efficiency treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described with reference to the accompanying drawings.

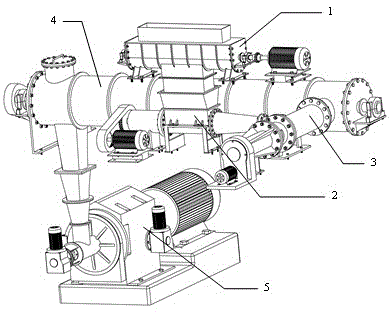

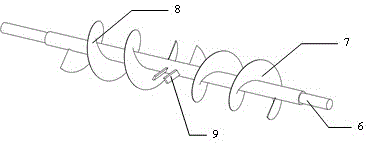

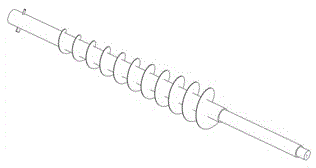

[0015] The screw agitating squeezer includes a screw squeezer 1, a plug screw conveyor 2 whose feed inlet communicates with the outlet of the screw squeezer 1, and a feed inlet that communicates with the outlet of the plug screw conveyor 2 The shredder 3, the heater 4 whose feed inlet communicates with the outlet of the shredder 3, the disc heat disperser 5 whose feed inlet communicates with the heater 4 outlet, is characterized in that the screw extruder On the first main shaft 6 of the pulp machine 1, two left-handed impellers 7 and right-handed impellers 8 with opposite rotation directions are arranged on the disk, and the main shaft 6 between the left-handed impeller 7 and the right-handed impeller 8 is also provided with stirring teeth 9; The upper disk of the second main shaft of the plug screw conveyor 2 is set as a variable compression ratio conical cantilever screw im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com