Treatment method for green cotton fiber

A treatment method and fiber technology, which is applied in the field of green cotton fiber treatment, can solve problems such as poor light fastness, lowering the grade of green cotton products, affecting product wearing performance and market development, etc., so as to improve the color fastness to soaping , Improving the effect of light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

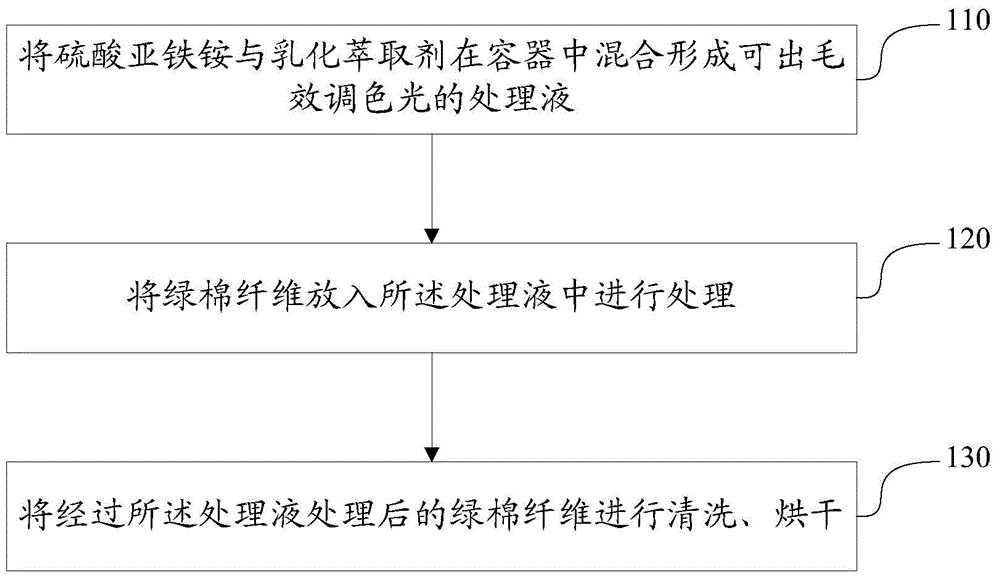

Method used

Image

Examples

Embodiment 1

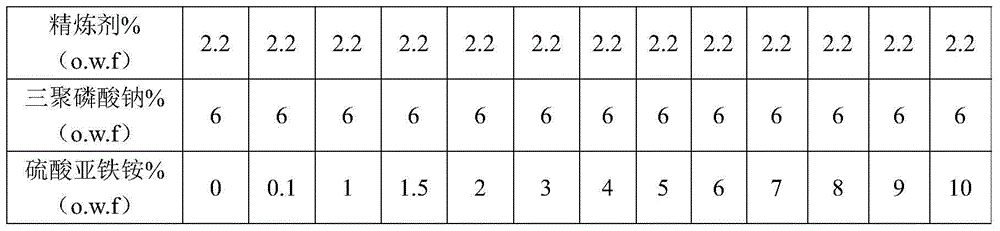

[0059] Adopt one-bath method to process green cotton fiber, as shown in table 1, namely refining agent 2.2% (o.w.f), sodium tripolyphosphate 6% (o.w.f), ferrous ammonium sulfate 0.1-10% (o.w.f) in bath ratio 1: 20. Treat the green cotton at 95°C for 60 minutes, then fully wash it three times with 80°C hot water, once in cold water, wring it out, and dry it at 100°C.

[0060] Table 1

[0061]

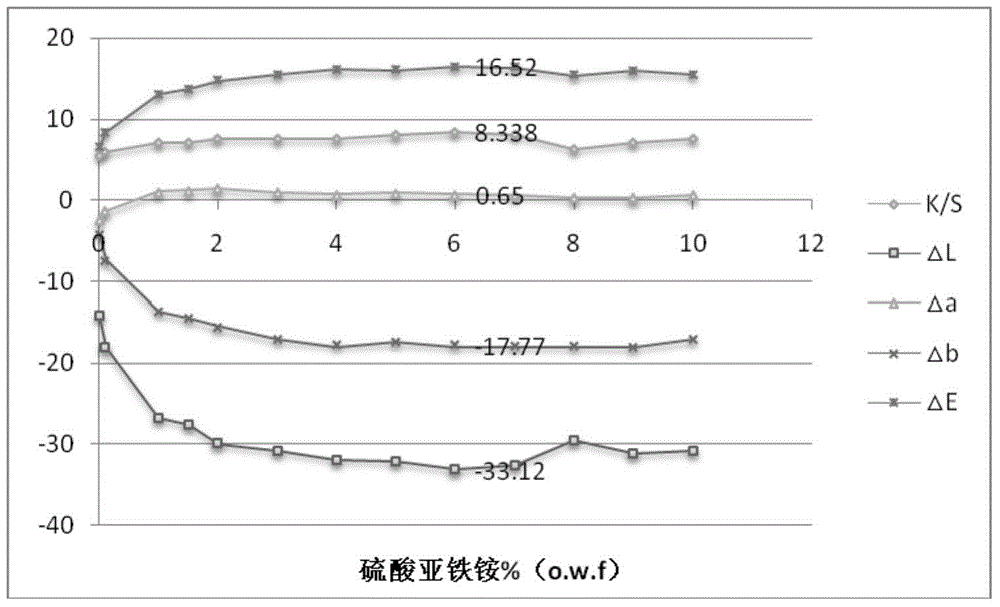

[0062] The difference in the amount of ferrous ammonium sulfate can make the green cotton produce different colors, as can be seen from Table 2 the relationship between the amount of ferrous ammonium sulfate and the color parameter index of the green cotton fiber after treatment. The color parameter indexes are K / S, L, a, b and ΔE. K / S value indicates the color depth; L indicates the brightness of the sample color, the larger the L value, the lighter the sample color, and the smaller the sample color is thicker; the larger the positive value of a, the redder the shade, and the negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com