Acidic color fixing agent and preparation method and application method thereof

An acidic color fixing agent and solvent technology, which is applied in the field of printing and dyeing auxiliaries, can solve the problems of fabrics that are easy to form color spots, color changes, and not resistant to concentrated acids, so as to avoid color spots, reduce color change, and improve The effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a preparation method for preparing the acidic color fixing agent involved in the present invention, which includes the following steps: adding resin, glacial acetic acid, solvent and active body to the reaction vessel to obtain the first mixed solution; stirring For the first mixed solution, heat the reaction vessel until the temperature of the first mixed solution reaches 95-102°C, and keep it warm for 30-45 minutes until the resin is fully dissolved to obtain the second mixed solution; the reaction vessel The temperature of the second mixed liquid in the mixture was lowered to 70°C, and a sulfonating agent was added dropwise to the reaction vessel to keep the reaction temperature lower than 80°C; after the dropwise addition of the sulfonating agent, the temperature was kept at 75 ℃-80℃, heat preservation reaction for 4-6 hours to obtain the third mixed solution; cool the third mixed solution to 45-55℃, add deionized water, continue s...

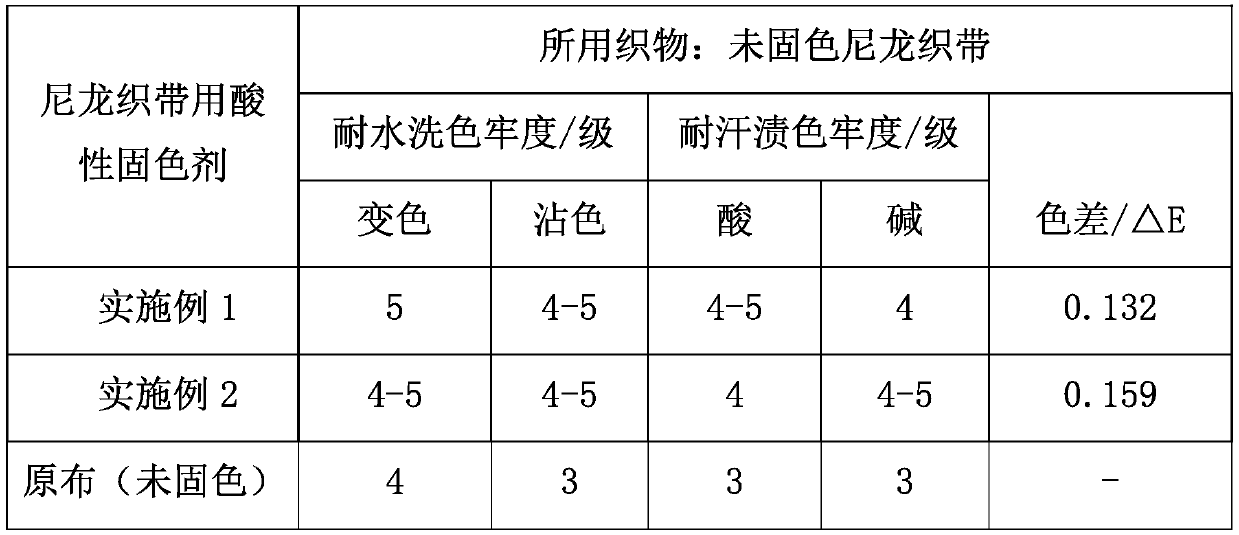

Embodiment 1

[0034]A preparation method provided by this embodiment is used to prepare the acidic color fixing agent involved in the present invention, in parts by weight, comprising the following steps: adding 45 parts of resin, 30 parts of glacial acetic acid, and 5 parts of fatty alcohol into the reaction vessel Polyoxyethylene ether sulfate and 10 parts of tripropylene glycol to obtain the first mixed solution; stir the first mixed solution, heat the reaction vessel with steam until the temperature of the first mixed solution reaches 95-102°C, and keep warm for the reaction 30-45 minutes, until the resin is fully dissolved to obtain the second mixed solution; the second mixed solution in the reaction vessel is cooled to 70°C, and 15 parts of concentrated sulfuric acid is added dropwise to the reaction vessel, keeping The reaction temperature is lower than 80°C. When the reaction temperature exceeds 80°C, cool down with circulating cooling water in time, and the time for dropping the con...

Embodiment 2

[0037] A preparation method provided by this embodiment is used to prepare the acidic color fixing agent involved in the present invention, in parts by weight, comprising the following steps: adding 42 parts of resin, 35 parts of glacial acetic acid, and 6 parts of cardanol into the reaction vessel Polyoxyethylene ether and 12 parts of diethylene glycol to obtain the first mixed solution; stir the first mixed solution, heat the reaction vessel with steam until the temperature of the first mixed solution reaches 95-102°C, and keep warm for the reaction 30-45 minutes, until the resin is fully dissolved to obtain the second mixed solution; the second mixed solution in the reaction vessel is cooled to 70°C, and 16 parts of concentrated sulfuric acid is added dropwise to the reaction vessel, keeping The reaction temperature is lower than 80°C. When the reaction temperature exceeds 80°C, cool down with circulating cooling water in time, and the time for dropping the concentrated sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com