Method for increasing dye uptake of cellulosic fiber dyed with natural dyes

A technology of cellulose fibers and natural dyes, applied in the field of natural dye dyeing, can solve environmental pollution and other problems, and achieve the effect of improving the dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Decamethylcyclopentasiloxane dye liquor dyes cellulose fibers.

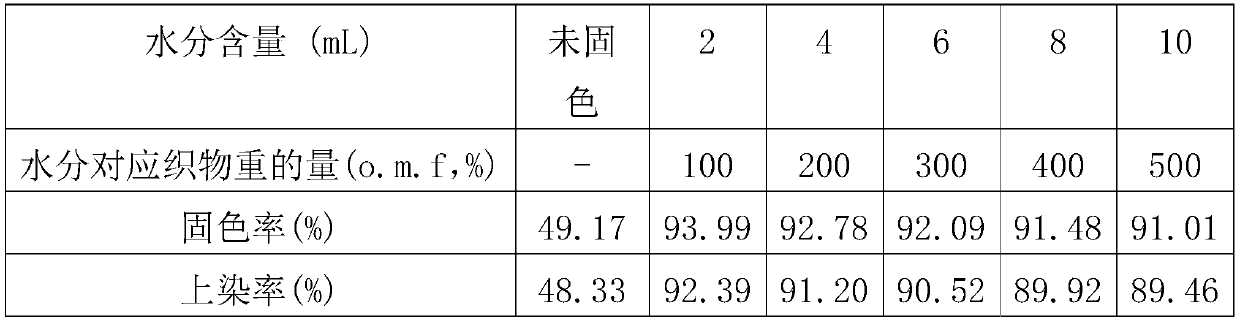

[0047] Take 5g of the surfactant AEO-3 and the co-surfactant n-octanol, stir until uniform, and prepare a co-surfactant solution. Take 2.5 g of the prepared auxiliary agent solution, add the decamethylcyclopentasiloxane solution to 100 mL, stir until uniform, and prepare the decamethylcyclopentasiloxane solution containing the auxiliary agent. Take 0.06g (3% o.m.f) of cocoa shell pigment, dissolve them in 1mL (50% o.m.f), 2mL (100% o.m.f), 4mL (200% o.m.f), 6mL (300% o.m.f), 8mL (400% o.m.f) and 10mL (500% o.m.f) water to prepare high-concentration cocoa shell pigment natural dye solutions containing different moisture contents, then add the prepared decamethylcyclopentasiloxane solution containing additives to 40mL, and stir until uniform , complete the preparation of decamethylcyclopentasiloxane dye solutions containing different water contents, and detect their absorbance, that is, the absorbance of th...

Embodiment 2

[0053] Decamethylcyclopentasiloxane dye liquor dyes cellulose fibers.

[0054] Take 5g of the surfactant AEO-3 and the co-surfactant n-octanol, stir until uniform, and prepare a co-surfactant solution. Take 2.5 g of the prepared auxiliary agent solution, add the decamethylcyclopentasiloxane solution to 100 mL, stir until uniform, and prepare the decamethylcyclopentasiloxane solution containing the auxiliary agent. Take 0.06g (3% o.m.f) of cocoa shell pigment and dissolve it in 2mL (100% o.m.f) of water to prepare a high-concentration cocoa shell pigment natural dye solution, then add the prepared decamethylcyclopentadiene containing additives Add the siloxane solution to 40mL, stir until uniform, and complete the preparation of the decamethylcyclopentasiloxane dye solution, and detect its absorbance, that is, the absorbance of the dye solution before dyeing, which is recorded as A0.

[0055] Take 2g of cotton cloth, soak them in 40mL (bath ratio 1:20) of decamethylcyclopentas...

Embodiment 3

[0060] Decamethylcyclopentasiloxane dye liquor dyes cellulose fibers.

[0061] Take 5g of the surfactant AEO-3 and the co-surfactant n-octanol, stir until uniform, and prepare a co-surfactant solution. Take 2.5 g of the prepared auxiliary agent solution, add the decamethylcyclopentasiloxane solution to 100 mL, stir until uniform, and prepare the decamethylcyclopentasiloxane solution containing the auxiliary agent. Take 0.06g (3% o.m.f) of cocoa shell pigment and dissolve it in 2mL (100% o.m.f) of water to prepare a high-concentration cocoa shell pigment natural dye solution, then add the prepared decamethylcyclopentadiene containing additives Add the siloxane solution to 40mL, stir until uniform, and complete the preparation of the decamethylcyclopentasiloxane dye solution, and detect its absorbance, that is, the absorbance of the dye solution before dyeing, which is recorded as A0.

[0062] Take 2g of cotton cloth, dip it into 40mL (bath ratio 1:20) of decamethylcyclopentasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com