Method for preparing Bi2Se3 thin film by virtue of magnetron sputtering process

A magnetron sputtering and thin film technology, applied in the preparation of Bi2Se3 thin films and thin film materials, can solve the problems of slow epitaxial growth rate, expensive preparation equipment, large energy consumption, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

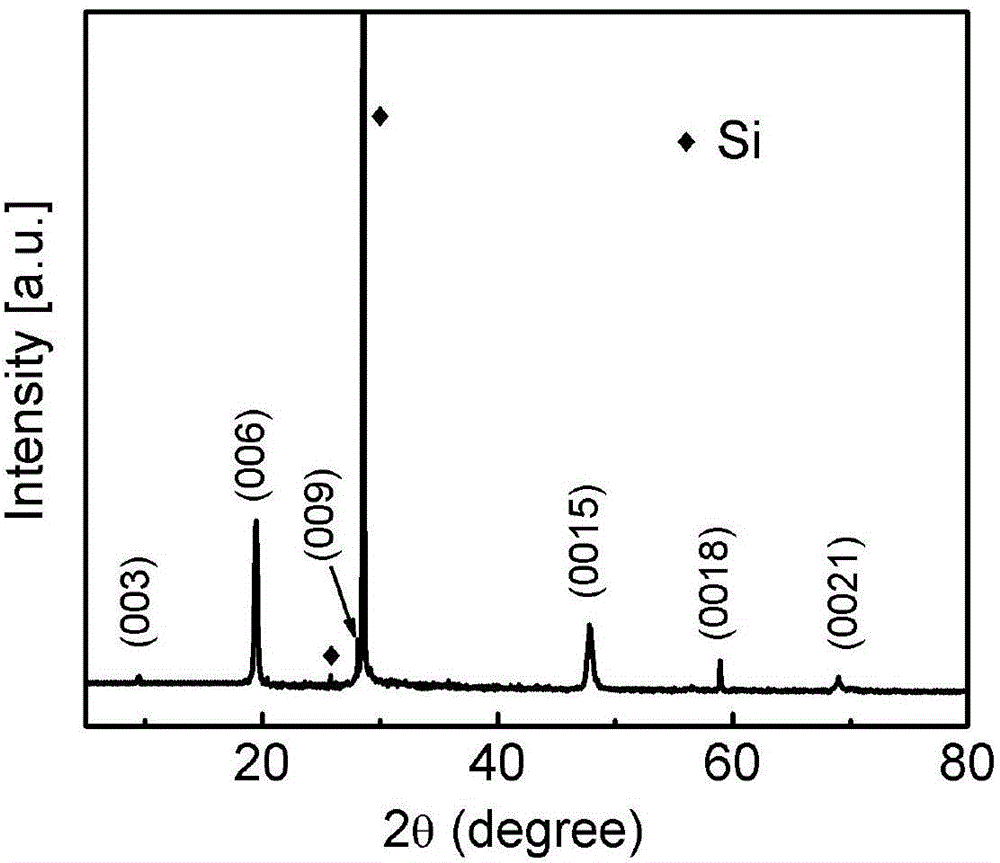

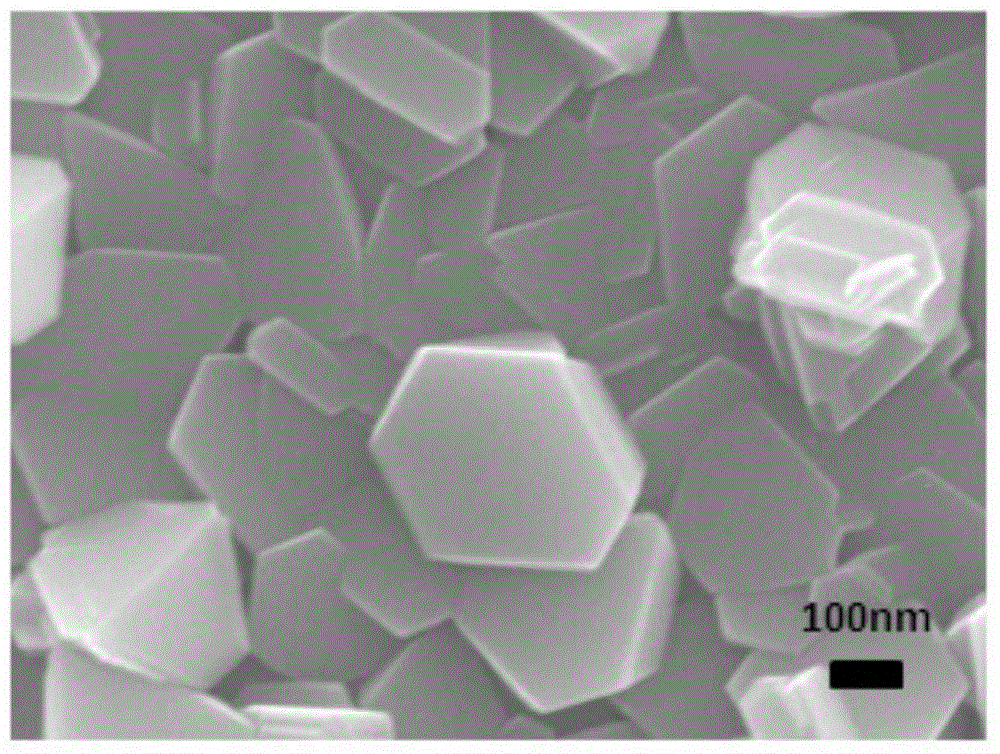

[0022] Preparation of Bi by a magnetron sputtering method 2 Se 3 The method of thin film, its step is:

[0023] a. Clean the substrate: ultrasonically clean the silicon substrate in acetone, ethanol, and deionized water for 10 minutes;

[0024] b. Sputtering preparation: dry the silicon substrate with hot nitrogen and place it on the substrate of the magnetron sputtering equipment, and install Bi with a purity of 99.99% on the sputtering target of the magnetron sputtering equipment 2 Se 3 For the target material, adjust the distance between the sputtering target and the silicon substrate to be 5 cm;

[0025] c. Sputtering Bi 2 Se 3 Thin films: evacuate the sputtering chamber to a pressure of 1.9×10 -4 Pa, and then pass in argon gas with a purity of 99.995%, so that the pressure of the sputtering chamber is 0.5Pa, adjust the substrate temperature to 360°C, and perform sputtering power to 6W / cm 2 , Sputtering deposition with a time of 60 seconds;

[0026] d. Post-anneali...

Embodiment 2

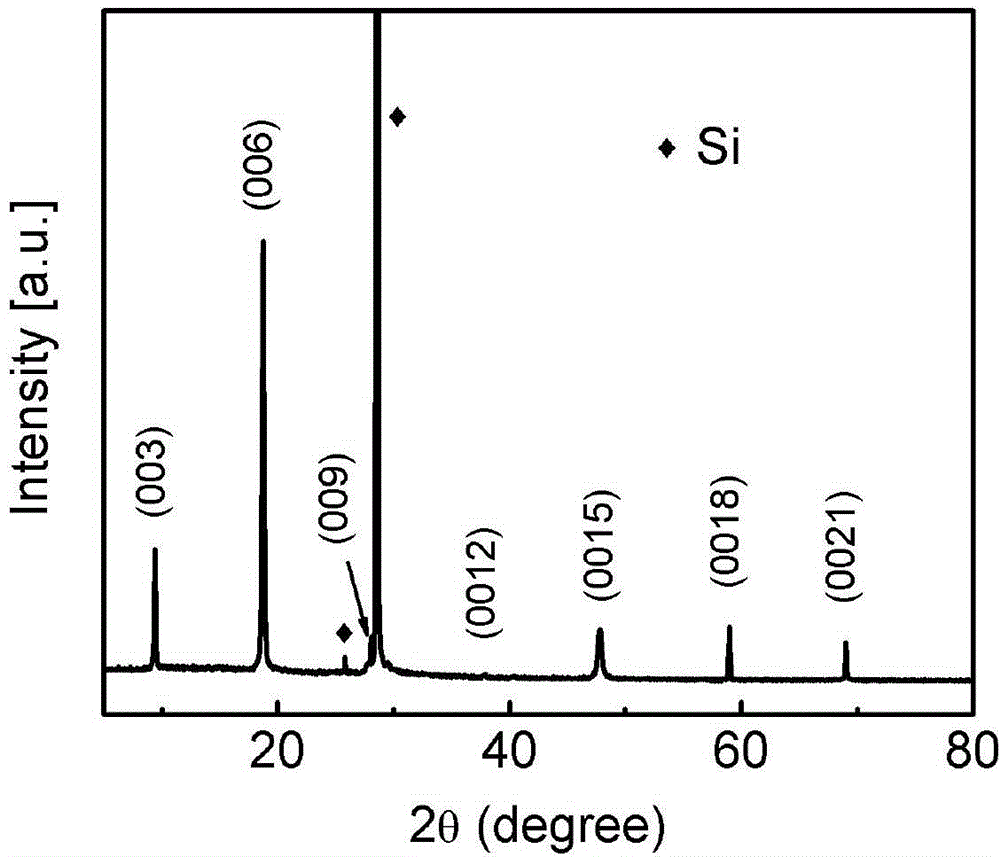

[0031] Preparation of Bi by a magnetron sputtering method 2 Se 3 The method of thin film, its step is:

[0032] a. Clean the substrate: ultrasonically clean the silicon substrate in acetone, ethanol, and deionized water for 15 minutes;

[0033] b. Sputtering preparation: dry the silicon substrate with hot nitrogen and place it on the substrate of the magnetron sputtering equipment, and install Bi with a purity of 99.99% on the sputtering target of the magnetron sputtering equipment 2 Se 3 Target material, adjust the distance from the sputtering target to the silicon substrate to be 6 cm;

[0034] c. Sputtering Bi 2 Se 3 Thin film: evacuate the sputtering chamber to a pressure of 1.8×10 -4 Pa, and then inject argon gas with a purity of 99.995%, so that the pressure of the sputtering chamber is 0.4Pa, adjust the substrate temperature to 360°C, and perform sputtering power to 4W / cm 2 , sputter deposition for 300 seconds;

[0035] d. Post-annealing treatment: the deposition ...

Embodiment 3

[0040] Preparation of Bi by a magnetron sputtering method 2 Se 3 The method of thin film, its step is:

[0041] a. Clean the substrate: ultrasonically clean the silicon substrate in acetone, ethanol, and deionized water for 20 minutes;

[0042] b. Sputtering preparation: dry the silicon substrate with hot nitrogen and place it on the substrate of the magnetron sputtering equipment, and install Bi with a purity of 99.99% on the sputtering target of the magnetron sputtering equipment 2 Se 3 Target material, adjust the distance from the sputtering target to the silicon substrate to be 7 cm;

[0043] c. Sputtering Bi 2 Se 3 Thin films: evacuate the sputtering chamber to a pressure of 1.6×10 -4 Pa, and then feed argon gas with a purity of 99.995%, so that the pressure of the sputtering chamber is 0.6Pa, adjust the substrate temperature to 360°C, and perform sputtering power to 5W / cm 2 , Sputtering deposition with a time of 600 seconds;

[0044] d. Post-annealing treatment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com