Preparation method of mg-zn-y-gd-zr alloy with high strength and high toughness

A high-toughness, high-strength technology, applied in the field of alloys and their preparation, can solve the problem of high rare earth content in alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

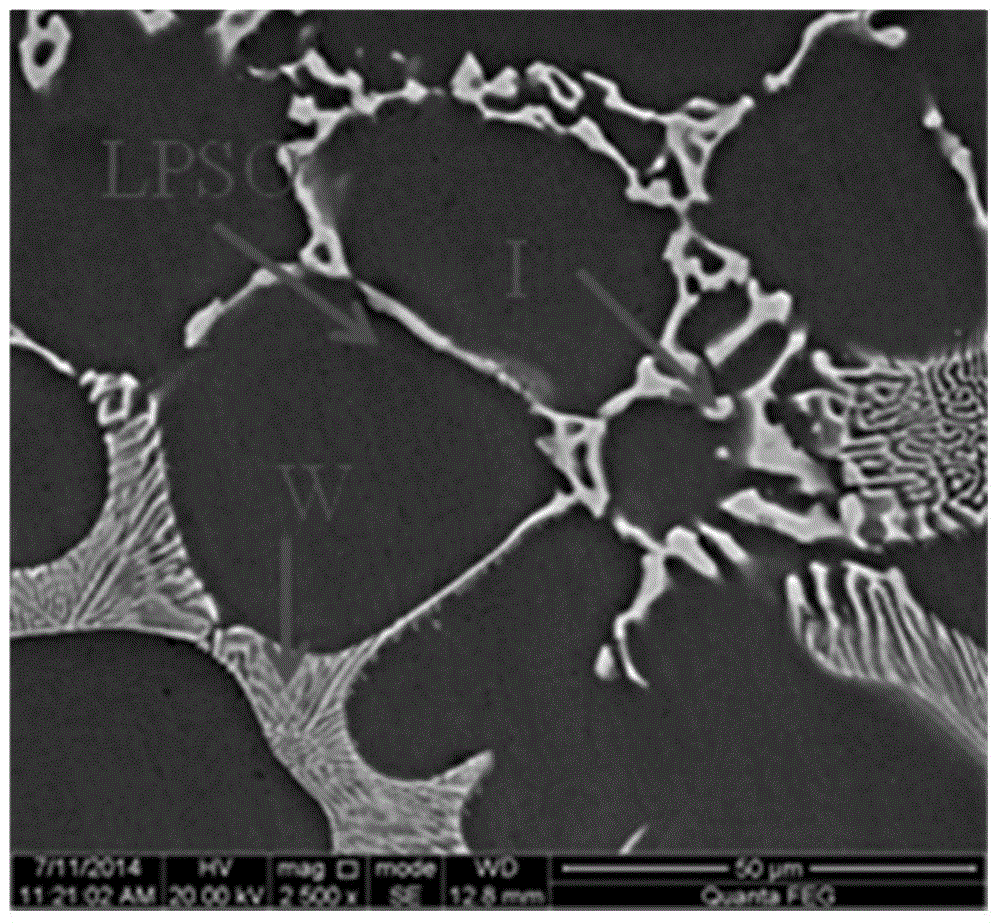

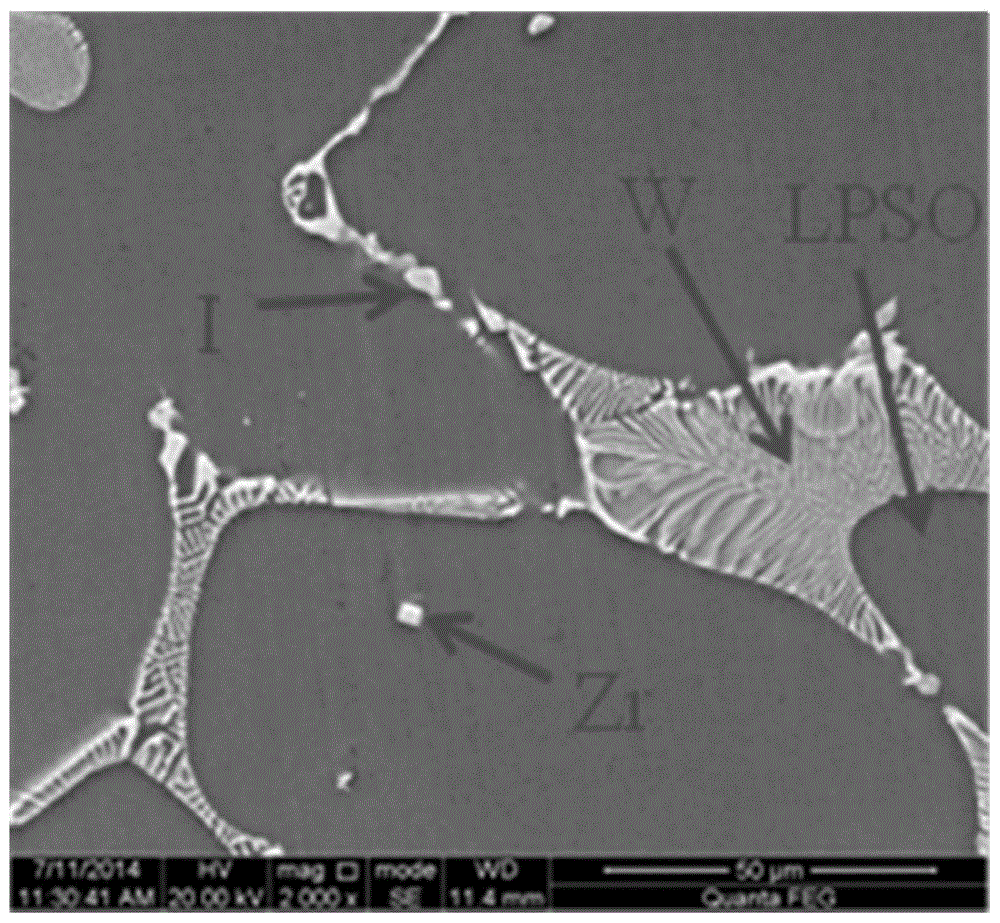

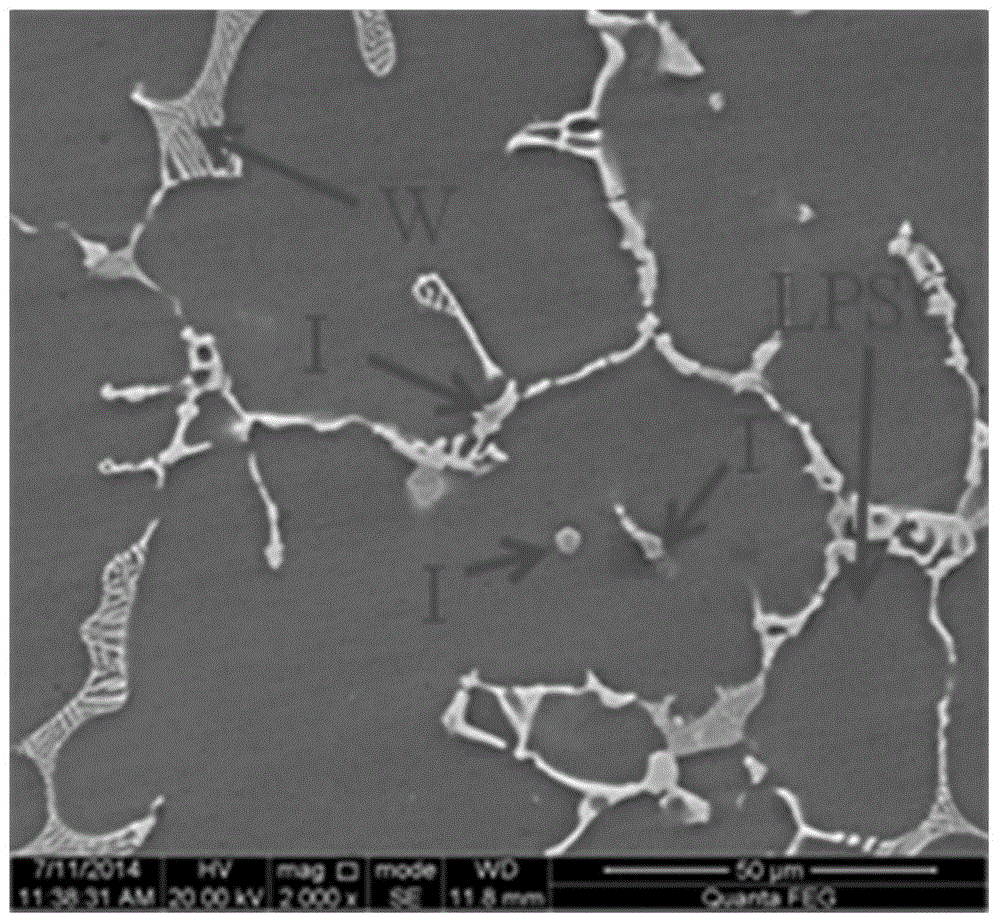

[0021] Specific Embodiment 1: In this embodiment, the high-strength and high-toughness Mg-Zn-Y-Gd-Zr alloy consists of 8-12% Zn, 1-6% Y, 1-6% Gd, 0.3-0.7% Zr and The balance is composed of Mg.

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the high-strength and high-toughness Mg-Zn-Y-Gd-Zr alloy consists of 8.12% Zn, 5.95% Y, 1.01% Gd, 0.31% Zr and The balance is composed of Mg. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: The difference between this embodiment and specific embodiment one or two is that the high-strength and high-toughness Mg-Zn-Y-Gd-Zr alloy consists of 10.06% Zn, 4.75% Y, 1.32% Gd, Composition of 0.46% Zr and balance Mg. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com