Reaction equipment and system and method for preparing reducing gas for gas-base shaft furnace

A technology of reaction equipment and gas-based shaft furnace, which is applied in the field of reducing gas for gas-based shaft furnace preparation, and can solve the problems of increased production cost of gas-based direct reduction process, increased investment and operating costs of gasification equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

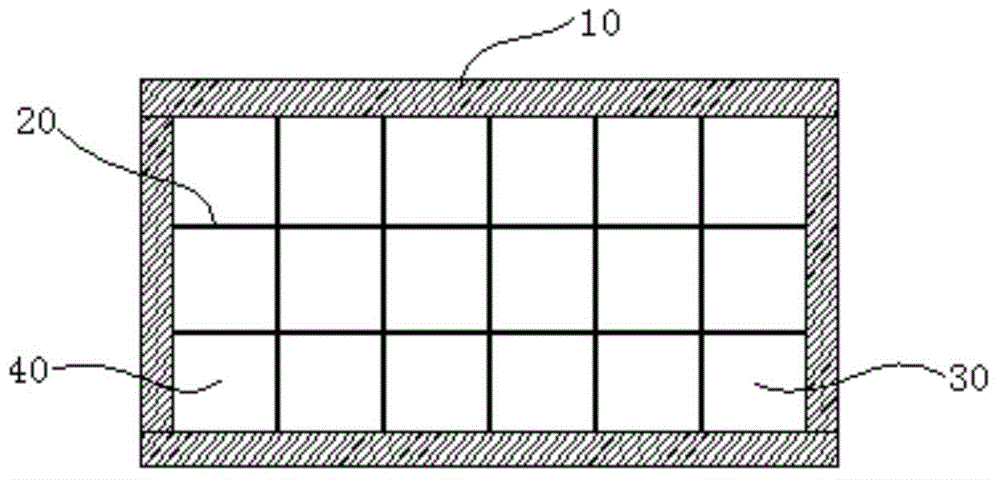

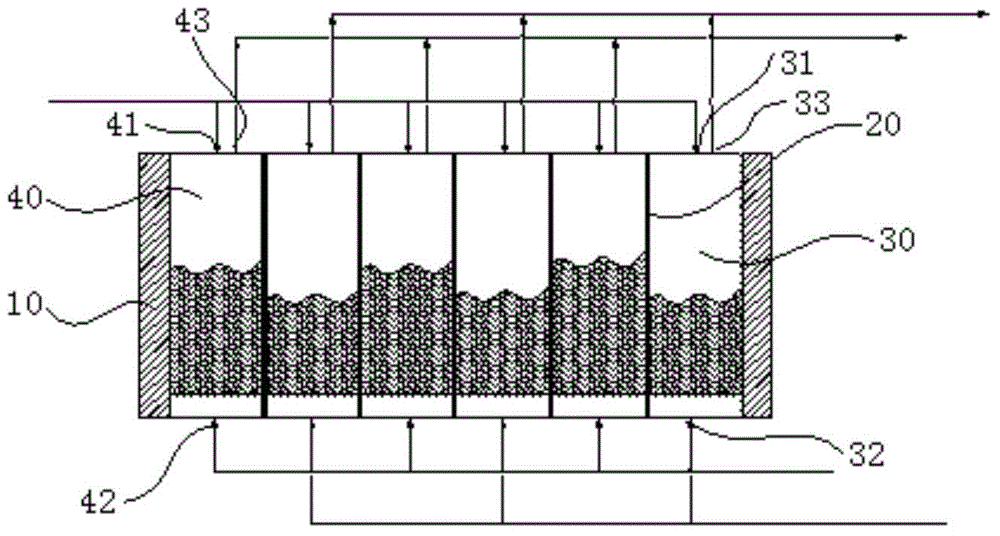

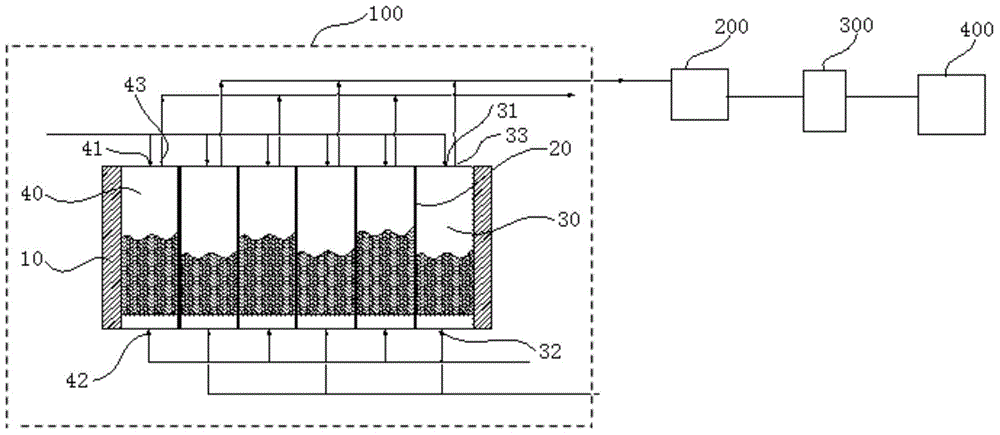

[0049] The system for preparing reducing gas for a gas-based shaft furnace according to a specific embodiment of the present invention includes: a reducing gas generating device 100 , a dust collector 200 , a water washing device 300 and a desulfurization and decarbonization device 400 .

[0050] According to a specific embodiment of the present invention, the above-mentioned reducing gas generating equipment 100 is the aforementioned reaction equipment, wherein the gasification chamber 30 is a gasification chamber, and the combustion chamber 40 is a combustion chamber; the dust collector 200 is connected with each The reducing gas outlet of the gasification chamber 30 is connected; the water washing device 300 is connected with the dust collector 200 for washing the reducing gas; the desulfurization and decarbonization device 400 is connected with the water washing device 300 for desulfurizing and decarbonizing the reducing gas.

[0051] Using the system for preparing reducing...

Embodiment 1

[0075] use as Figure 4 The shown system for producing reducing gas for a gas-based shaft furnace produces reducing gas for a gas-based shaft furnace. The specific steps are as follows: first, coal and air are delivered to the combustion chamber 40 from the coal inlet at the top of the combustion chamber 40 and the air inlet at the bottom, and the coal is burned to provide heat for the gasification chamber 30, and the combustion chamber 40 The combustion temperature inside is about 1000-1050 degrees Celsius, and the heat is transferred to the gasification chamber 30 through heat conduction and radiation heat transfer, so that the temperature in the gasification chamber 30 reaches 900-950 degrees Celsius.

[0076] The raw coal inlet at the top of the gasification chamber 30 and the water vapor inlet at the bottom are respectively transported into the heated gasification chamber 30 for gasification raw coal and saturated water vapor, and the gasification raw coal and water vapor...

Embodiment 2

[0079] use as Figure 4 The shown system for producing reducing gas for a gas-based shaft furnace produces reducing gas for a gas-based shaft furnace. The specific steps are as follows: first, coal and air are delivered to the combustion chamber 40 from the coal inlet at the top of the combustion chamber 40 and the air inlet at the bottom, and the coal is burned to provide heat for the gasification chamber 30, and the combustion chamber 40 The combustion temperature inside is about 900-950 degrees Celsius, and the heat is transferred to the gasification chamber 30 through heat conduction and radiation heat transfer, so that the temperature in the gasification chamber 30 reaches 800-900 degrees Celsius.

[0080] From the raw coal inlet at the top of the gasification chamber 30 and the steam inlet at the bottom, the gasified raw coal and water vapor are respectively delivered to the heated gasification chamber 30, wherein the water vapor contains a small amount of air and makes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com