Preparation method of isomaltooligosacharide

A technology for isomalto-oligosaccharide and maltotriose, which is applied in the field of preparation of isomalto-oligosaccharide to achieve the effects of improving tolerance, improving functionality and improving flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

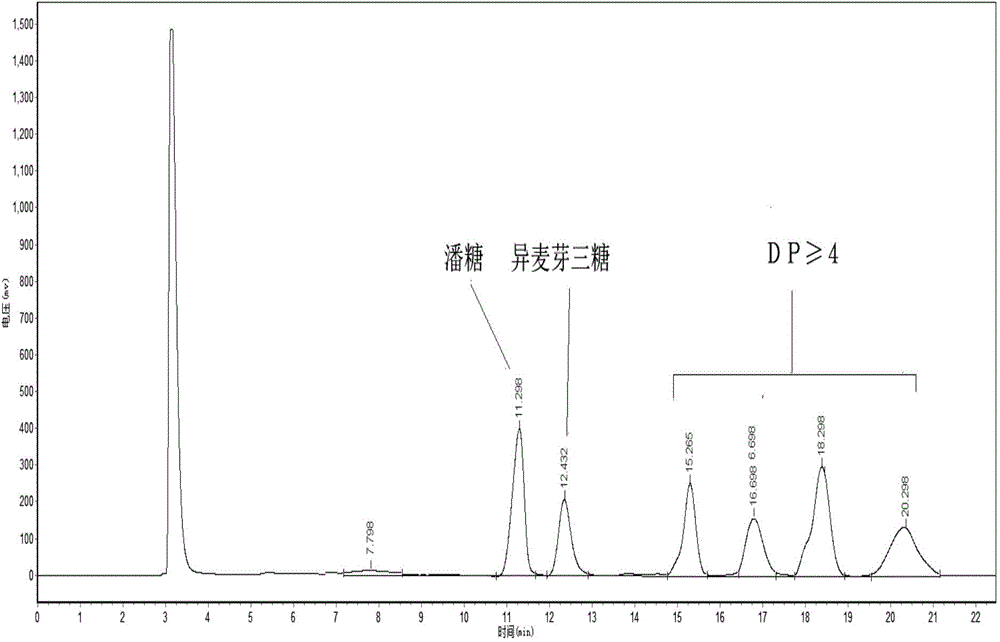

Image

Examples

Embodiment 1

[0048] A preparation method of isomaltooligosaccharide, comprising the steps of:

[0049] (1) Add water to the starch raw material to adjust the starch slurry concentration to 20 degrees Baume, adjust the pH value to 5.2, then add high temperature resistant α-amylase, the amount of high temperature resistant α-amylase is 0.5 per ton of starch raw material L, made starch slurry;

[0050] (2) The starch slurry prepared in step (1) is liquefied by the second spraying, the first spraying liquefaction temperature is 100°C, and the second spraying liquefaction temperature is 121°C to obtain a liquefied liquid with a DE value of 4%. ;

[0051] (3) After cooling the liquefied liquid obtained in step (2) to 50°C, adjust the pH to 6.0, then add maltotriose-forming enzyme and pullulanase, the amount of maltotriose-forming enzyme added is 1 ton of starch raw material Add 500ml, the amount of pullulanase added is 300ml per ton of starch raw material, after 36 hours of heat preservation a...

Embodiment 2

[0058] A preparation method of isomaltooligosaccharide, comprising the steps of:

[0059] (1) Add water to the starch raw material to adjust the starch slurry concentration to 22 degrees Baume, adjust the pH value to 6.0, then add high temperature resistant α-amylase, the amount of high temperature resistant α-amylase is 0.8 per ton of starch raw material L, made starch slurry;

[0060] (2) The starch slurry prepared in step (1) is liquefied by the second injection, the liquefaction temperature of the first injection is 105°C, and after the second injection liquefaction temperature is 130°C, a liquefied liquid with a DE value of 8% is obtained ;

[0061] (3) After cooling the liquefied liquid prepared in step (2) to 53°C, adjust the pH to 6.2, then add maltotriose-forming enzyme and pullulanase, the amount of maltotriose-forming enzyme added is 1 ton of starch raw material Add 600ml, the amount of pullulanase added is 400ml per ton of starch raw material, after 45 hours of h...

Embodiment 3

[0069] A preparation method of isomaltooligosaccharide, comprising the steps of:

[0070] (1) Add water to the starch raw material to adjust the starch slurry concentration to 25 degrees Baume, adjust the pH value to 6.2, then add high temperature resistant α-amylase, the amount of high temperature resistant α-amylase is 1.0 per ton of starch raw material L, made starch slurry;

[0071] (2) The starch slurry prepared in step (1) is liquefied by the second injection, the liquefaction temperature of the first injection is 110°C, and after the second injection liquefaction temperature is 140°C, a liquefied liquid with a DE value of 10% is obtained ;

[0072] (3) After cooling the liquefied liquid prepared in step (2) to 55°C, adjust the pH to 6.5, then add maltotriose-forming enzyme and pullulanase, the amount of maltotriose-forming enzyme added is 1 ton of starch raw material Add 800ml, the amount of pullulanase added is 600ml per ton of starch raw material, after 56 hours of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com