Nonstandard diesel oil treatment technology and apparatus thereof

A treatment process and treatment device technology, applied in the field of deep processing of oil products, can solve problems such as reduced production efficiency, oil loss, product color, excessive sulfur content, etc., to ensure quality stability, reduce environmental pressure, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

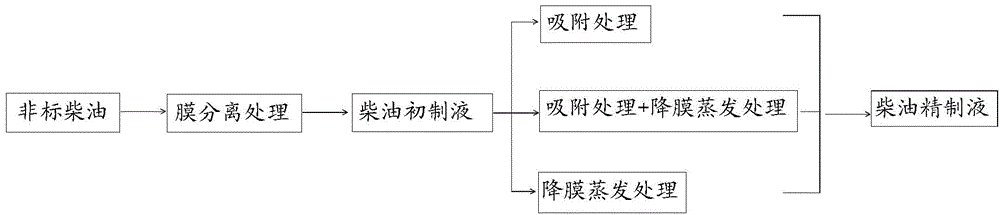

Method used

Image

Examples

Embodiment 1

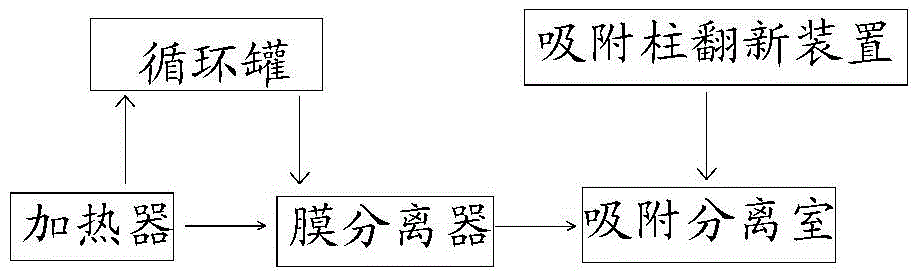

[0047] The non-standard diesel processing device of this embodiment also includes an adsorption separation chamber, the inlet end of which is provided with a second liquid inlet pump, and an adsorption column is arranged in the adsorption separation chamber; the adsorption separation chamber is used to separate Impurities and sulfur-containing components that are very close in volume and polarity to diesel components will be entrained through the treatment membrane and mixed in the diesel. The impurities and sulfur-containing components can be adsorbed and filtered through adsorption treatment, so that the primary diesel liquid can be made into refined diesel liquid.

[0048] Further, it also includes an adsorption column refurbishment device, which includes a heating device, a blower and a cyclone separation tank, which are connected to each other by pipelines, thereby providing a suitable temperature and aerobic environment for the adsorbed saturated molecular sieve , in thi...

Embodiment 2

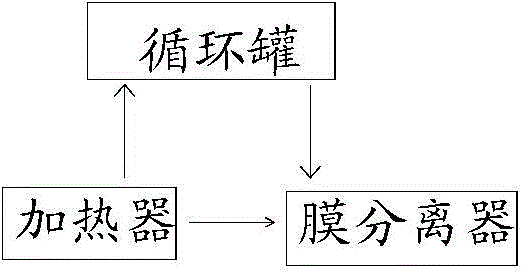

[0050] The non-standard diesel processing device of this embodiment also includes a circulation tank, the outlet of the circulation tank is connected to the membrane separator, and the inlet of the circulation tank is connected to the outlet of the heater; the circulation tank is used to store The non-standard diesel oil in the machine is waiting to participate in the next cycle until all the non-standard diesel oil is extracted.

Embodiment 3

[0052] The non-standard diesel processing device of this embodiment also includes a falling film evaporator, the falling film evaporator includes a heat exchanger, a gas-liquid separation tank and a vacuum system, the heat exchanger is connected to the gas-liquid separation tank, the The vacuum system is connected with the heat exchanger and the gas-liquid separation tank, so that the internal environment of the heat exchanger and the gas-liquid separation tank is in a vacuum, the heat exchanger includes more than two heat exchange tubes, and the falling film evaporator The top of the tank is provided with a liquid separator, which is set correspondingly to the liquid inlet of the heat exchanger, and the top of the gas-liquid separation tank is connected to a condenser through a pipeline; the falling film evaporator adopts vacuum evaporation, which reduces impurities Evaporation temperature, on the one hand, avoids the deterioration and decomposition of organic molecules at hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com