Non-migration and degradable antimicrobial polyester film and preparation method thereof

A polyester film and polyester technology, applied in the field of antibacterial, can solve the problems of aggravating the harm of white pollution to human beings, and the high cost of recycling and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

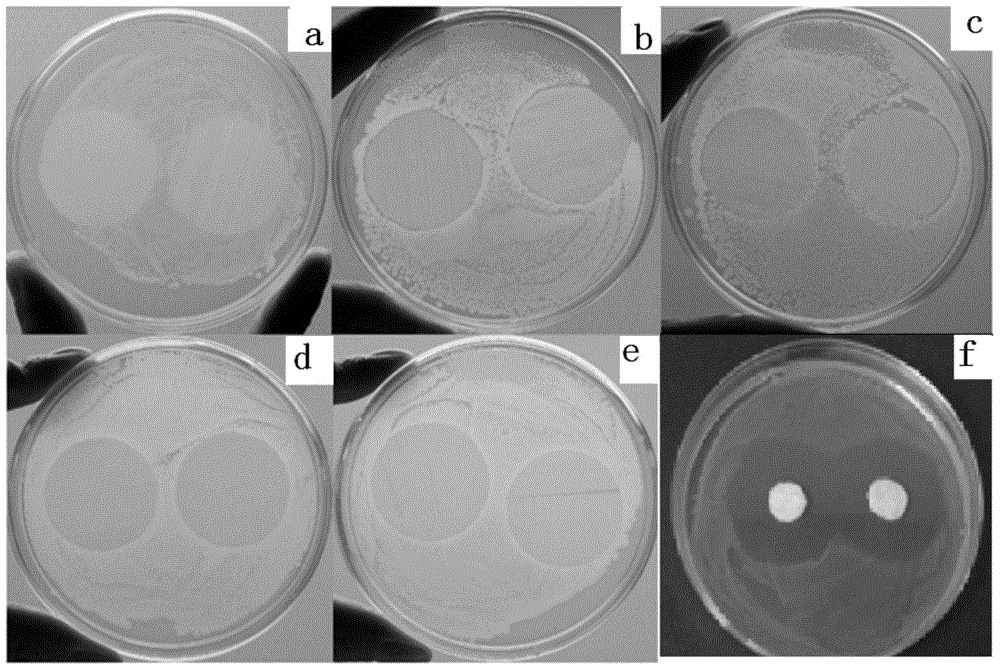

Image

Examples

preparation example Construction

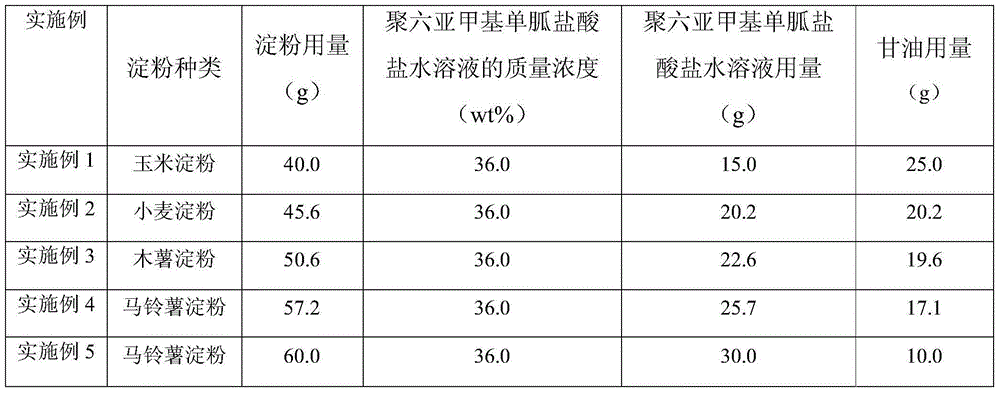

[0028] The preparation method of antibacterial thermoplastic starch granules: take the required amount of each component in Table 1, and then prepare antibacterial thermoplastic starch granules as follows:

[0029] Starch, polyhexamethylene monoguanidine hydrochloride aqueous solution with a mass concentration of 36% and glycerol are mixed and stirred uniformly to obtain a mixture, and the mixture is kneaded, melted, extruded and granulated to obtain antibacterial thermoplastic starch granules.

[0030] The operating conditions for the preparation of antibacterial thermoplastic starch granules are as follows: the mixture is fed into a twin-screw extruder, and the detailed processing parameters are listed below:

[0031] Equipment: ZSK 18mm MEGAlab laboratory extruder

[0032] Temperature distribution: 85 / 110 / 135 / 155 / 170 / 160 / 150 (°C, from feeding area to die)

[0033] Melt temperature: 160-165°C

[0034] Screw speed: 150-180rpm

[0035] The product at the die of the extruder...

Embodiment 1-5

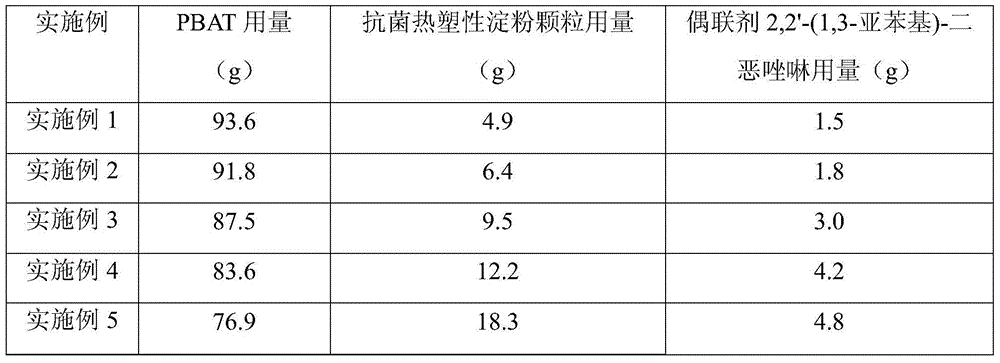

[0037] Table 2 The amount of each component required for the preparation of antibacterial polyester particles in Examples 1-5

[0038]

[0039] The antibacterial thermoplastic starch granules described in the above Table 2 are the antibacterial thermoplastic starch granules prepared in the first step of Example 1-5.

[0040] The method for the preparation of antibacterial polyester particles: take the required amount of each component in Table 2, then prepare antibacterial polyester particles according to the following method:

[0041] First, mix PBAT and antibacterial thermoplastic starch granules and dry them at a temperature of 70-80°C for 20-24 hours, then mix the dried PBAT, dried antibacterial thermoplastic starch granules and 2,2'-(1,3- Phenyl)-bisoxazolines are mixed, and after mixing, the mixture is kneaded, melted, extruded and granulated to obtain antibacterial polyester particles.

[0042] The operating conditions for the preparation of antibacterial polyester ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com