Porous metal modifier and preparation method of composite material

A porous metal and composite technology, applied in the coating and other directions, can solve the problems of difficulty in reaching the ideal level, unfavorable processing, limited bonding strength, etc., and achieve the effects of improving bonding force, environmental protection in the processing process, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

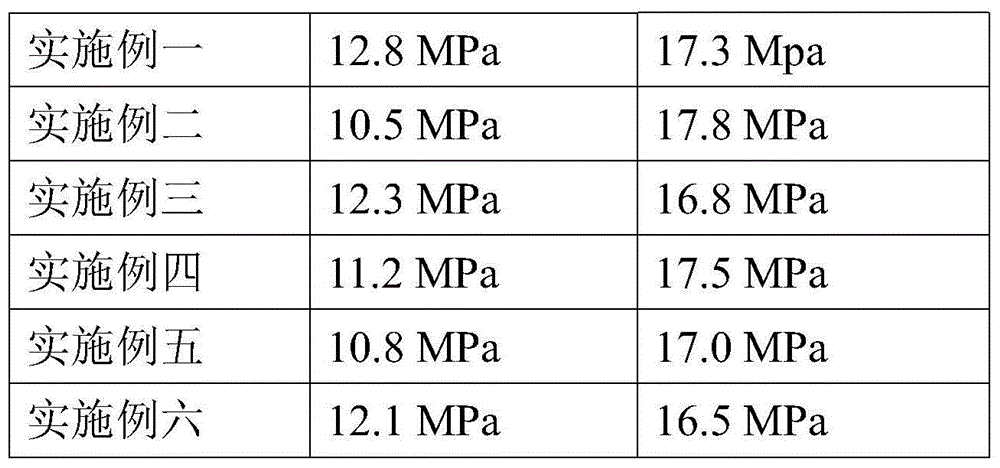

Examples

preparation example Construction

[0030] According to an embodiment of the present invention, a method for preparing a composite material includes the following steps:

[0031] Form a porous metal substrate with micron-scale pores on the surface through powder metallurgy sintering technology;

[0032] Surface treatment of the porous metal substrate with a porous metal modifier, the porous metal modifier contains an organic ester and an organic acid blend for improving the difference in surface tension coefficient between the metal substrate and plastic;

[0033] Injection molding is performed on the metal base material and the plastic treated by the porous metal modifier to obtain a composite material integrating the metal and the plastic.

[0034] The materials involved in the method of the present invention are as follows.

[0035] 1. Metal: The metal base material with micron-sized holes and shaped metal substrates prepared by powder metallurgy can be, but not limited to, Cr-Ni stainless steel such as SUS3...

Embodiment 1

[0052] 1. Porous metal modifier:

[0053] In 1000 parts of solvent (wherein 450 parts of propanol, 550 parts of ethanol), add the raw material that has following weight ratio:

[0054] 1) 80 parts of organic ester

[0055] Wherein: 80 parts of dimethyl terephthalate;

[0056] 2) 325 parts of organic acid

[0057] Among them: 225 parts of maleic acid and 100 parts of malic acid.

[0058] 2. A preparation method of porous metal composite material, specifically comprising the following steps:

[0059] 1) Provide a shaped porous metal substrate, the porous metal substrate is a shaped metal substrate prepared by powder metallurgy, which can be Cr-Ni stainless steel such as SUS304, SUS316, SUS405, SUS429, SUS403 One of Cr series stainless steel.

[0060] 2) Carry out chemical degreasing treatment on the metal substrate with a degreasing agent sold on the market to remove oil stains on the metal surface; the chemical degreasing temperature is 80°C, and the degreasing time depend...

Embodiment 2

[0066] 1. Porous metal modifier:

[0067] In 1000 parts of solvent (wherein 250 parts of propanol, 650 parts of ethanol, 100 parts of acetone), add the raw material that has following weight ratio:

[0068] 1) 145 parts of organic ester

[0069] Among them: 60 parts of dimethyl terephthalate, 85 parts of diethyl terephthalate;

[0070] 2) 120 parts of organic acid

[0071] Among them: 75 parts of maleic acid and 45 parts of malic acid.

[0072] 2. A preparation method of porous metal composite material, specifically comprising the following steps:

[0073] 1) Provide a shaped porous metal substrate, the porous metal substrate is a shaped metal substrate prepared by powder metallurgy, which can be Cr-Ni stainless steel such as SUS304, SUS316, SUS405, SUS429, SUS403 One of Cr series stainless steel.

[0074] 2) Carry out chemical degreasing treatment on the metal substrate with a degreasing agent sold on the market to remove oil stains on the metal surface; the chemical deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com