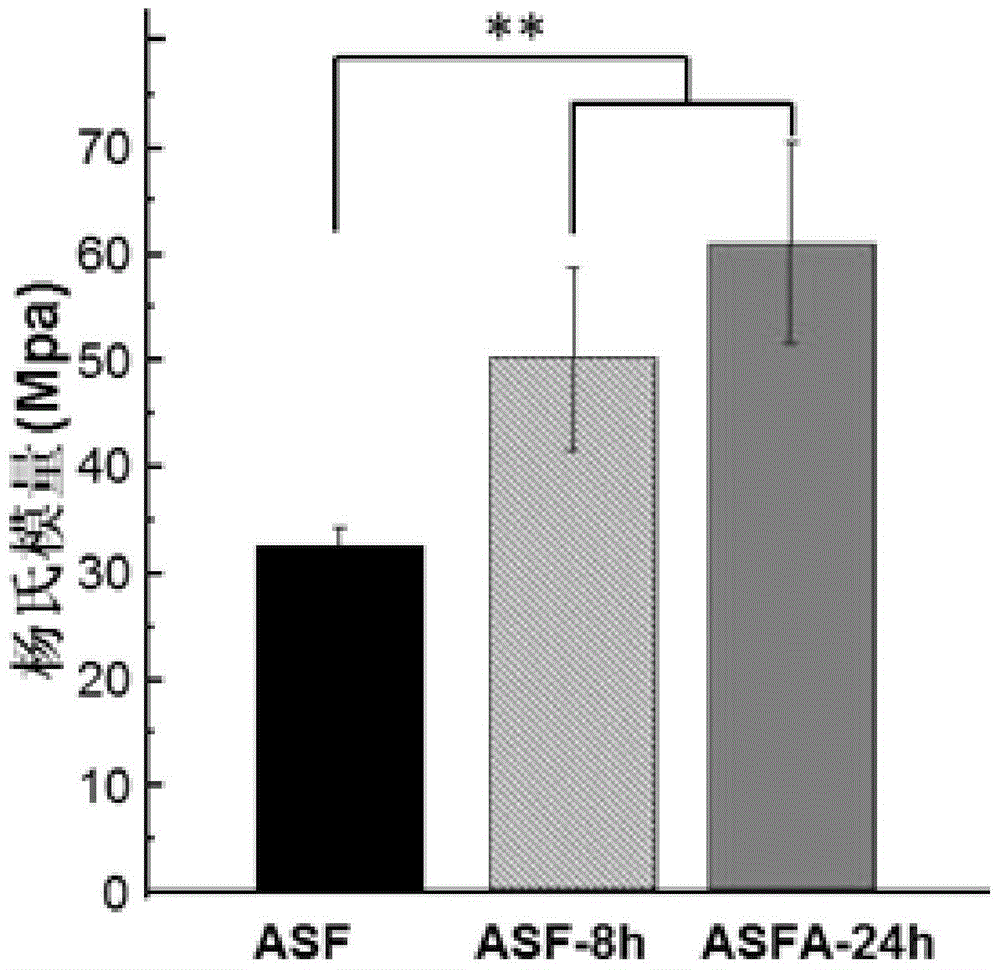

A method to enhance the mechanical properties of silk protein membranes through biomineralization

A technology of biomineralization and silk protein, applied in the field of biomineralization of silk protein film, can solve the problems of reduced mechanical properties of silk protein film, incomplete mineralization, etc., and achieves short preparation cycle, short production cycle and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the present embodiment, the method for biomineralization to improve the mechanical properties of silk protein film comprises the following steps in turn:

[0031] (1) Dissolving the tussah silk fibroin powder in a hexafluoroacetone machine solvent to obtain a tussah silk fibroin protein solution, then adding the tussah silk fibroin protein solution dropwise to a plastic plate, and drying to obtain a silk protein film;

[0032] (2) Soak the silk protein film in step (1) in 75% alcohol and treat it for 12 hours to obtain an insoluble tussah silk protein film;

[0033] (3) soak the tussah silk fibroin protein film in step (2) in CaCl with a pH value of 6.0 2 Soak in the aqueous solution for half an hour to obtain a premineralized tussah silk fibroin film;

[0034] (4) Add 1g of nano-hydroxyapatite powder to 40mL of deionized water, then add 0.64mL of HCl with a concentration of 0.1 moles per liter, and ultrasonicate for 10 minutes to form a uniform milky white suspensi...

Embodiment 2

[0041] The biomineralization method of the tussah silk fibroin that promotes cell growth in the present embodiment comprises the following steps successively:

[0042](1) dissolving silk fibroin powder in hexafluoroisopropanol to obtain a silk fibroin solution, then adding the silk fibroin solution dropwise to a plastic plate, and drying to obtain a silk fibroin film;

[0043] (2) soaking the silk fibroin film in step (1) in 75% alcohol for 24 hours to obtain an insoluble silk fibroin film;

[0044] (3) Soak the silk fibroin film in step (2) in CaCl with a pH value of 7.0 2 Soak in the aqueous solution for half an hour to obtain a premineralized silk fibroin film;

[0045] (4) Add 2g of nano-hydroxyapatite powder to 40mL of deionized water, then add 0.64mL of HCl with a concentration of 0.1 moles per liter, and ultrasonicate for 10 minutes to form a uniform milky white suspension, which is hydroxyapatite working fluid;

[0046] (5) Add 3gNaCl and 200mL deionized water to th...

Embodiment 3

[0051] In the present embodiment, the method for biomineralization to improve the mechanical properties of silk protein film comprises the following steps in turn:

[0052] (1) Dissolving the tussah silk fibroin powder in a hexafluoroacetone machine solvent to obtain a tussah silk fibroin protein solution, then adding the tussah silk fibroin protein solution dropwise to a plastic plate, and drying to obtain a silk protein film;

[0053] (2) Soak the silk protein film in step (1) in 75% alcohol and treat it for 12 hours to obtain an insoluble tussah silk protein film;

[0054] (3) soak the tussah silk fibroin protein film in step (2) in CaCl with a pH value of 6.0 2 Soak in the aqueous solution for half an hour to obtain a premineralized tussah silk fibroin film;

[0055] (4) Add 1g of nano-hydroxyapatite powder to 40mL of deionized water, then add 0.64mL of HCl with a concentration of 0.1 moles per liter, and ultrasonicate for 10 minutes to form a uniform milky white suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com