Emulsion collapse agent and preparation method thereof

A technology of anti-slumping agent and emulsion, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of single product and lack of mature industrial products, and achieve the effect of mild reaction conditions and simple and feasible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

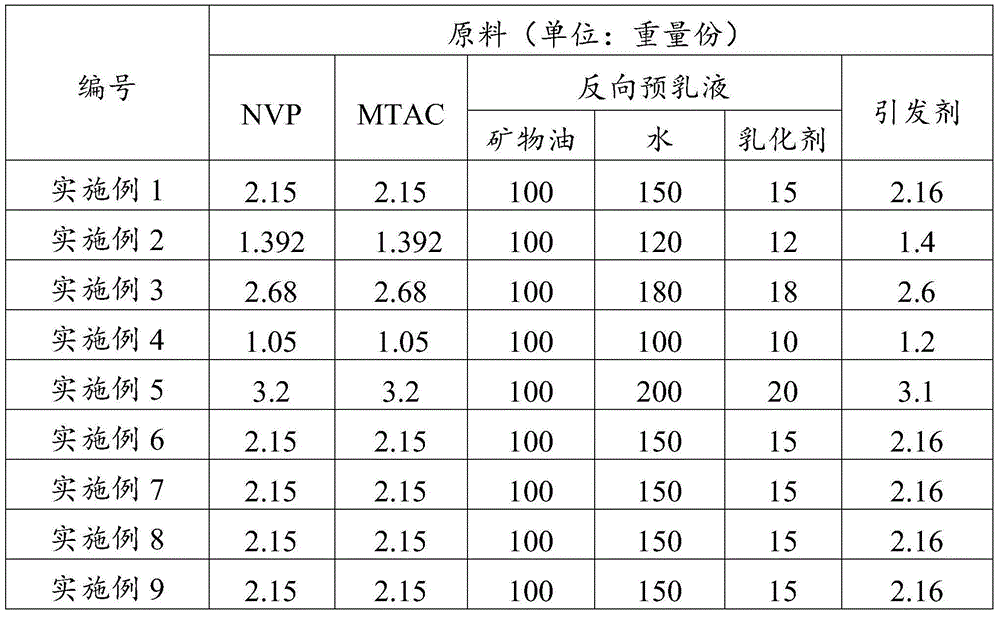

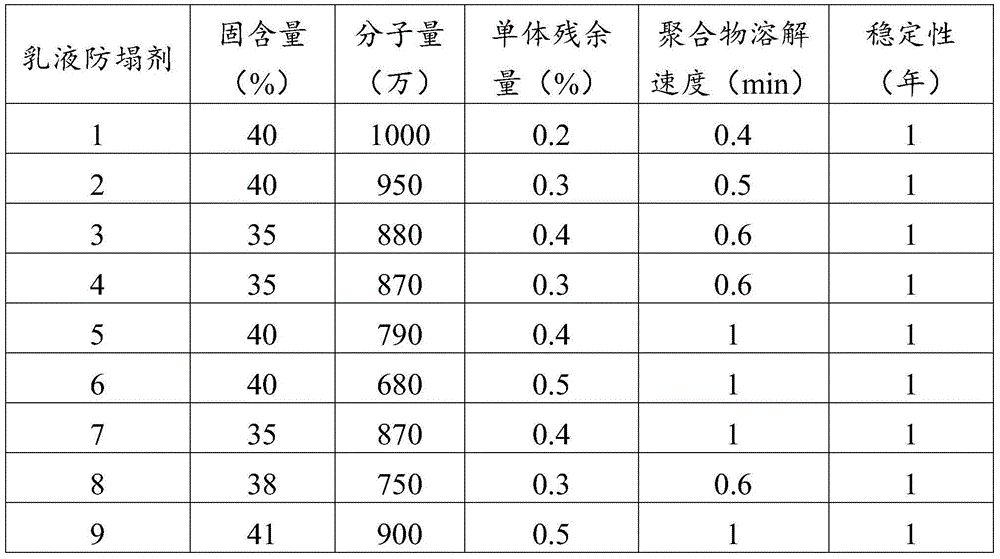

[0038] Examples 1-9 are used to illustrate the preparation method of the emulsion anti-slumping agent provided by the present invention.

[0039] According to the component contents listed in Table 1, the emulsion anti-slump agent was prepared.

[0040] Put mineral oil, water and emulsifier in a four-necked bottle, stir and mix at a constant temperature of 40°C to obtain a reverse pre-emulsion for later use, mix PCM and MTCA in proportion to obtain a mixture in a dropping funnel, and pass nitrogen and Under the condition of stirring (speed 800rpm / min), the mixture of PCM and MTCA is added dropwise to the reverse pre-emulsion at a speed of 20ml / min, continue to stir and pass nitrogen gas for 20min, add initiator, and continue to pass nitrogen gas for 15min to obtain the emulsion Anti-slump agents 1-9.

[0041] Table 1

[0042]

[0043] In embodiment 1-9, the specific selection of each component is as follows:

[0044] In Example 1-5, the initiator is composed of ammonium ...

Embodiment 6

[0046] The emulsion anti-slump agent was prepared according to the method of Example 1, except that the initiator was composed of hydrogen peroxide and ferrous sulfate, and the weight ratio of the two was 1:1.5.

Embodiment 7

[0048] The emulsion anti-slump agent was prepared according to the method of Example 1, except that the initiator was composed of hydrogen peroxide and ferrous sulfate, and the weight ratio of the two was 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com