Preparation method for photoinitiator bis(2,4,6-trimethylbenzoyl)phenylphosphine oxide

A technology of trimethylbenzoyl and phenylphosphine oxide, applied in the chemical industry, can solve problems such as unsafe yield, and achieve the effects of reducing production cost, mild conditions, and avoiding pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

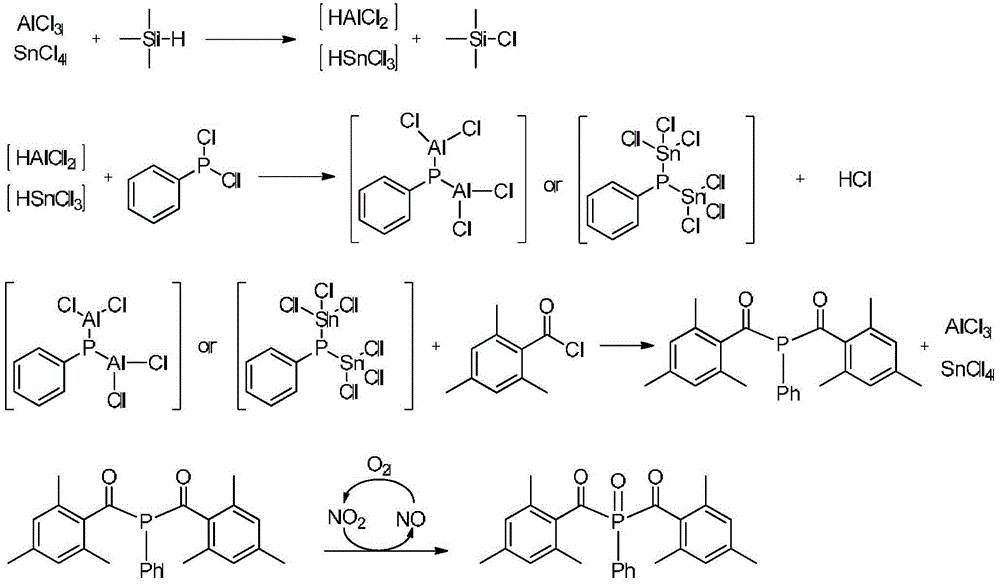

[0028] A kind of preparation method of two (2,4,6-trimethylbenzoyl) phenyl phosphine oxides of photoinitiator, the steps are as follows:

[0029] (1) Under nitrogen protection, add 100ml of toluene as solvent and aluminum trichloride (0.28mol, 37.2g) to the 250ml reaction bottle, at room temperature, stir and add trimethylsilane (0.25mol, 0.25mol, 18.5g), and continued to stir for 0.5 hours; then slowly add phenylphosphine dichloride (0.1mol, 19.4g) dropwise to the reaction flask after heating up to 80°C, and control the rate of addition to keep the reaction temperature constant. After the phosphine was added dropwise, continue to stir for 3 hours to obtain two (aluminum dichloride) phosphine salt intermediates;

[0030] (2) When the temperature of the reaction flask drops to 50°C, slowly add 2,4,6-trimethylbenzoyl chloride (0.22mol, 40g) dropwise into the reaction flask. After the addition is complete, continue heating to control the reaction temperature In the range of 70-8...

Embodiment 2

[0035] (1) Add 200ml toluene as solvent and aluminum trichloride (0.56mol, 74.4g) to the 500ml reaction flask under nitrogen protection, at room temperature, stir and add trimethylsilane (0.5mol, 37.0g), and keep stirring for 45 Minutes; then heat up to 70-80°C, slowly add phenylphosphine dichloride (0.2mol, 38.8g) dropwise to the reaction flask, keep the reaction temperature constant, and continue stirring after the addition of phenylphosphine dichloride is completed In 3 hours, two (aluminum dichloride) phosphonium salt intermediates were obtained;

[0036] (2) Lower the temperature of the reaction flask to 50°C, add 2,4,6-trimethylbenzoyl chloride (0.44mol, 80.0g) dropwise to the reaction flask, and continue heating after the addition is completed, at 100°C Under the conditions of reaction for 4.5 hours, the intermediate product bis(2,4,6-trimethylbenzoyl)phenylphosphine was obtained;

[0037] (3) Cool the reaction flask to 50°C, feed excess nitrogen dioxide gas into the r...

Embodiment 3

[0041] (1) Add 200ml of toluene as solvent and aluminum trichloride (0.56mol, 74.4g) to a 500ml reaction flask under nitrogen protection, at room temperature, stir and add trimethylsilane (0.5mol, 37.0g), and continue stirring for 30min Then be warming up to 100 ℃, slowly dropwise add phenylphosphine dichloride (0.2mol, 38.8g) in reaction flask, keep reaction temperature constant, after treating that phenylphosphine dichloride is added dropwise, continue to stir for 3 hours, Obtain bis (aluminum dichloride) phosphonium salt intermediate;

[0042] (2) Lower the temperature of the reaction flask to 50°C, add 2,4,6-trimethylbenzoyl chloride (0.44mol, 80.0g) dropwise to the reaction flask, and continue heating after the addition is completed, at 100°C Under the conditions of reaction for 4 hours, the intermediate product bis(2,4,6-trimethylbenzoyl)phenylphosphine was obtained;

[0043] (3) The reaction flask is cooled to room temperature, and excessive nitrogen dioxide gas is pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com