A kind of preparation method of high whiteness bone ceramic

A technology with high whiteness and bone quality, applied in the field of ceramics, can solve problems such as low whiteness and poor color, achieve high whiteness, low cost, and improve the yield of good products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A high-whiteness bone ceramic, the raw material of the high-whiteness bone ceramic body and its content by mass percentage are: 5% feldspar, 2% talc, 8% kaolin, 9% quartz, and 10% alumina %, bone meal 66%.

[0033] The raw materials of the high-whiteness bone ceramic glaze and their contents by mass percentage are: 40% feldspar, 8% talc, 10% quartz, 12% calcite, 5% zinc oxide, 5% barium carbonate, porcelain powder 20%.

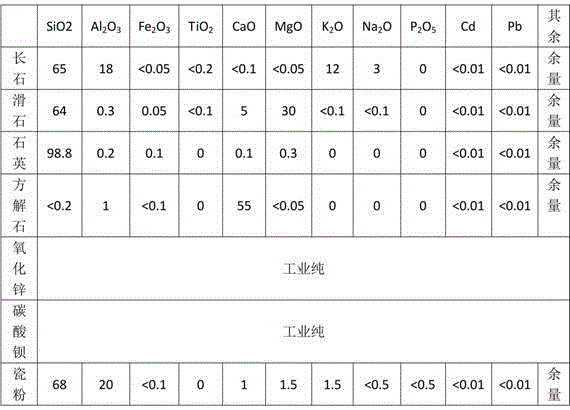

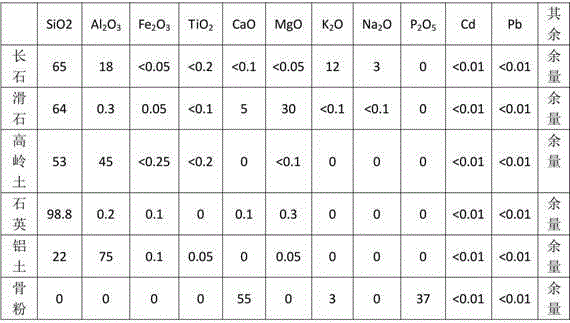

[0034] See Table 1 for the chemical composition of high-whiteness bone ceramic body raw materials by mass percentage, and see Table 2 for the chemical composition of high-whiteness bone ceramic glaze raw materials by mass percentage. Cd and Pb must be strictly controlled for each raw material. The percentage content of elements should be lower than 0.01%, so as to improve the color and whiteness of bone ceramics from the source.

[0035] A method for preparing high-whiteness bone ceramics, comprising the following steps:

[0036] a. Preparing blanks:...

Embodiment 2

[0044] A high-whiteness bone ceramic, the raw materials of the high-whiteness bone ceramic body and their contents by mass percentage are: 7% talc, 3% talc, 9% kaolin, 11% quartz, and 13% alumina , bone meal 57%.

[0045] The raw materials of the high-whiteness bone ceramic glaze and their contents by mass percentage are: 40% feldspar, 8% talc, 10% quartz, 12% calcite, 5% zinc oxide, 5% barium carbonate, porcelain powder 20%.

[0046] See Table 1 for the chemical composition of high-whiteness bone ceramic body raw materials by mass percentage, and see Table 2 for the chemical composition of high-whiteness bone ceramic glaze raw materials by mass percentage. Cd and Pb must be strictly controlled for each raw material. The percentage content of elements should be lower than 0.01%, so as to improve the color and whiteness of bone ceramics from the source.

[0047] A method for preparing high-whiteness bone ceramics, comprising the following steps:

[0048]a. Preparing blanks: ...

Embodiment 3

[0056] A high-whiteness bone ceramic, the raw material of the high-whiteness bone ceramic body and its content by mass percentage are: 6% feldspar, 2.5% talc, 8.5% kaolin, 10% quartz, 12% alumina %, bone meal 61%.

[0057] The raw materials of the high-whiteness bone ceramic glaze and their contents by mass percentage are: 40% feldspar, 8% talc, 10% quartz, 12% calcite, 5% zinc oxide, 5% barium carbonate, porcelain powder 20%.

[0058] See Table 1 for the chemical composition of high-whiteness bone ceramic body raw materials by mass percentage, and see Table 2 for the chemical composition of high-whiteness bone ceramic glaze raw materials by mass percentage. Cd and Pb must be strictly controlled for each raw material. The percentage content of elements should be lower than 0.01%, so as to improve the color and whiteness of bone ceramics from the source.

[0059] A method for preparing high-whiteness bone ceramics, comprising the following steps:

[0060] a. Preparing blanks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com