C60 full-manufactured sand super high-rise pump concrete

A technology for pumping concrete and machine-made sand, which is applied in the field of building materials, can solve problems such as poor workability and no public reports of concrete, and achieve the effects of reducing production costs, improving work performance, and reducing cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

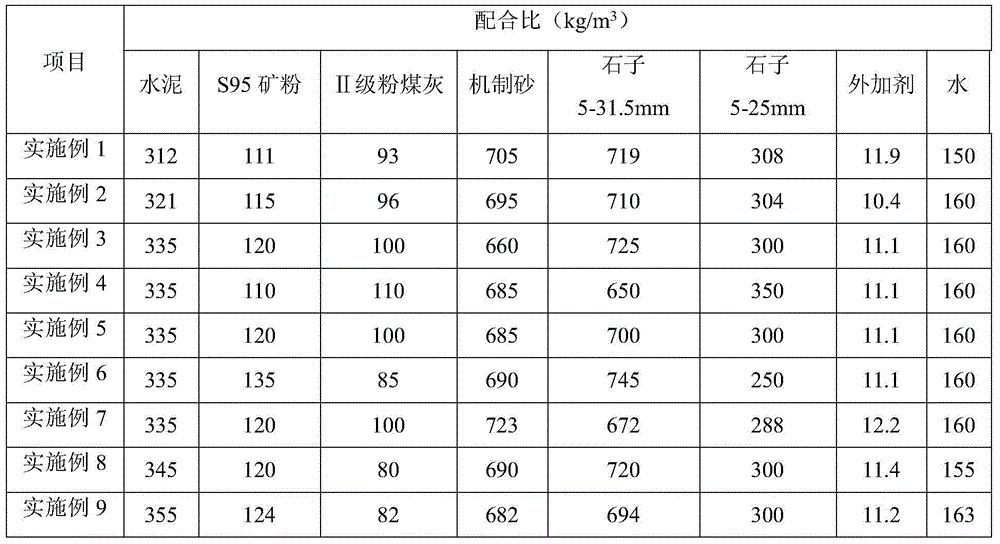

Embodiment 1~9

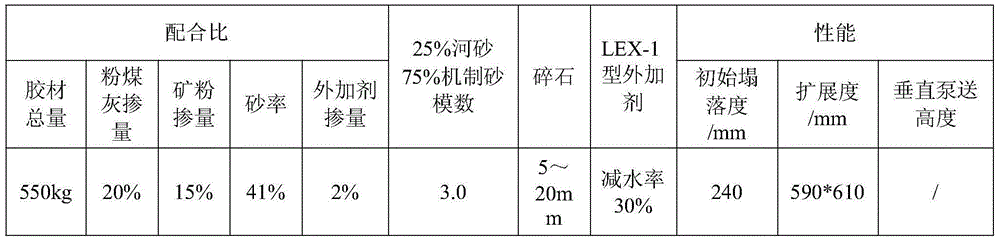

[0042] The present invention has carried out a series of test mixes to concrete by adopting different slag powder and fly ash content, different sand rates and water-cement ratios, and draws the mixing ratio as shown in Table 3, but if other different water-reducing ratios are used The modification of the admixture in various equivalent substitution forms falls within the scope of the claims of the present invention.

[0043] Table 3. C60 fully machine-made sand ultra-high pumping concrete mix ratio

[0044]

[0045] Convert the above mix ratio into 45L concrete raw material in proportion, and mix it in a small concrete mixer with a rated volume of 60L. The steps are: (1) each trial mix first mixes the mortar composed of cement, sand and water according to the mix ratio and a small amount of stones, Rinse the chamber in the mixer; (2) Start the mixer, add stones, sand and cement into the mixer in turn, dry mix for 30s, then add water (admixture mixed in water) slowly, after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com