Green cycle process for preparing activated carbon material for supercapacitors by using rice husks

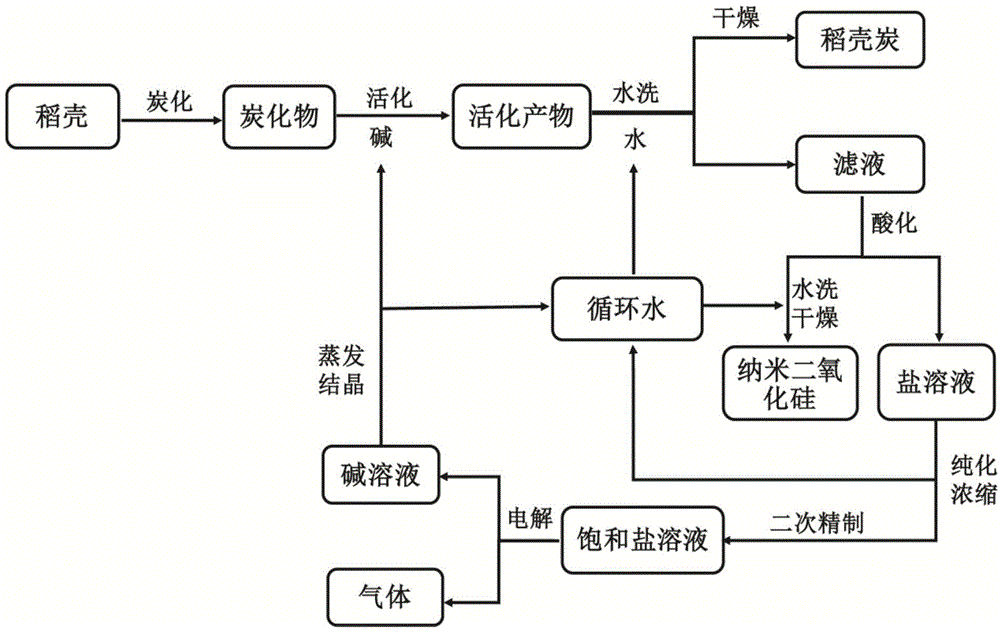

A technology of supercapacitor and activated carbon, which is applied in the field of green recycling process, can solve the problems of high water consumption, large discharge of waste liquid, activated carbon cannot be used for supercapacitors, etc., and achieves the effect of reducing production cost and solving the problem of waste water pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Rice husk is cleaned, dried and ground;

[0025] (2) Carbonizing the ground rice husks in the above step (1) under nitrogen protection at 450° C. for 2 hours to obtain carbonized rice husks;

[0026] (3) Mix the carbonized product obtained in the above step (2) with KOH at a mass ratio of 1:3, add a certain amount of water and mix evenly, dry, control the heating rate of 10°C / min, and activate at 750°C for 1h;

[0027] (4) Soak the activated product in water at 90°C, filter, wash with boiling water until neutral, and dry at 100°C for 12 hours to obtain a rice husk-based activated carbon material with a specific surface area of 3235cm2 / g and an average pore size of 2.0nm. The specific capacitance in 6M KOH solution is 331F / g. After 2000 cycles of charging and discharging at a current density of 1A / g, the specific capacitance retention rate is 93.5%. When the current density increases from 1A / g to 10A / g, the capacitance The retention rate is 67.2%;

[0028] (5) Re...

Embodiment 2

[0036] (1) Rice husk is cleaned, dried and ground;

[0037] (2) carbonizing the ground rice husks in the above step (1) under argon protection at 450°C for 2 hours to obtain carbonized rice husks;

[0038] (3) Mix the carbonized product obtained in the above step (2) with NaOH at a mass ratio of 1:4, add a certain amount of water to mix evenly, dry, control the heating rate of 10°C / min, and activate at 800°C for 2h;

[0039] (4) Soak the activated product in water at 90-100°C, filter, wash with boiling water to neutrality, and dry at 120°C for 12 hours to obtain a rice husk-based activated carbon material with a specific surface area of 2753cm2 / g and an average pore size of 2.3nm. Rice husk charcoal at 1M H 2 SO 4 The specific capacitance measured in the material is 305F / g, and the specific capacitance retention rate is 96.8% after 10,000 cycles of charging and discharging at a current density of 1A / g. When the current density increases from 1A / g to 10A / g, the capacitance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com