Anti-ultraviolet heat insulation car film

An anti-ultraviolet and automotive film technology, which is applied in the direction of coating, layered products, and synthetic resin layered products, can solve the problems of single function of automotive film, no anti-ultraviolet function of heat insulation layer, poor heat insulation effect, etc., and achieve The effect of good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

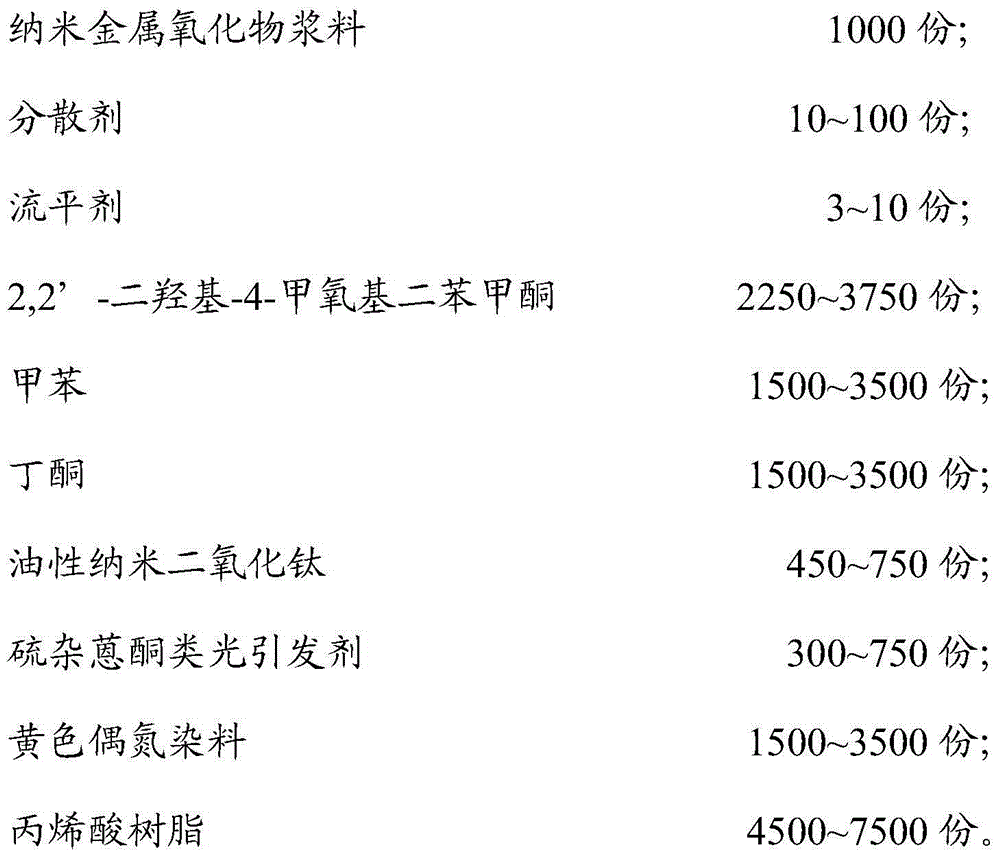

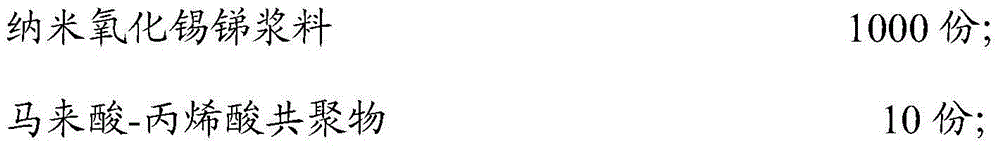

[0031] An anti-ultraviolet and heat-insulating automobile film is characterized in that it includes two layers of films, which are respectively a PET composite film and an ETFE film layer, and an anti-ultraviolet heat-insulating slurry is coated between the PET composite film and the ETFE film layer material, and glue is coated between the anti-ultraviolet and heat-insulating slurry and the two layers of film. The components of the UV-resistant and heat-insulating slurry are as follows:

[0032]

[0033]

[0034] Prepared as follows:

[0035] Step 1: Weigh 1000 parts of nano-antimony tin oxide slurry and 3000 parts of toluene into a polytetrafluoroethylene container, and stir at a speed of 25000 rpm;

[0036] Step 2: Weigh 10 parts of maleic acid-acrylic acid copolymer and 10 parts of polyethyl acrylate into the above-mentioned polytetrafluoroethylene container and heat to 30-80°C with constant speed;

[0037] Step 3: 500 parts of toluene and 3500 parts of butanone are...

Embodiment 2

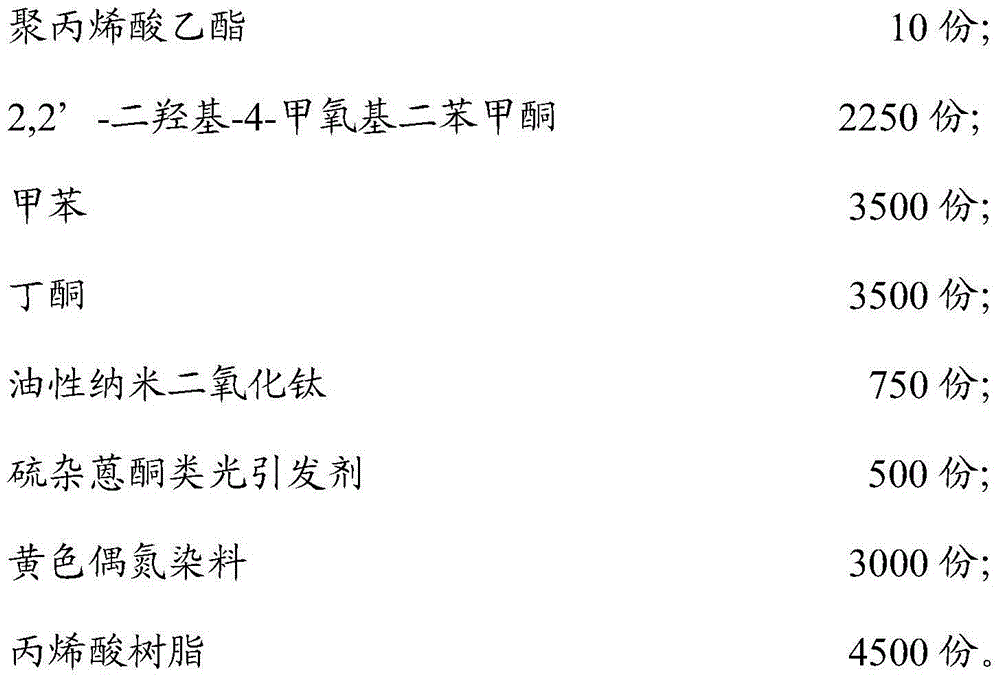

[0047] An anti-ultraviolet and heat-insulating automobile film is characterized in that it includes two layers of films, which are respectively a PET composite film and an ETFE film layer, and an anti-ultraviolet heat-insulating slurry is coated between the PET composite film and the ETFE film layer material, and glue is coated between the anti-ultraviolet and heat-insulating slurry and the two layers of film. The components of the UV-resistant and heat-insulating slurry are as follows:

[0048]

[0049]

[0050] Prepared as follows:

[0051] Step 1: Weigh 1000 parts of nano-zinc gallium oxide slurry and 2500 parts of toluene into a glass container, raise the temperature to 30°C, stir evenly, and rotate at 10000rpm;

[0052] Step 2: Weigh 10 parts of polypropyl ether modified trisiloxane and pour it into a glass container to continue heating and stirring;

[0053] Step 3: 1000 parts of toluene and 3500 parts of butanone are mixed to form a mixed solution;

[0054] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com