A flame-retardant polyolefin wood-plastic co-extrusion profile and its preparation method

A polyolefin, extrusion technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem of low flame retardant level, improve the flame retardant safety performance, expand the scope of application, improve The effect of safety fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

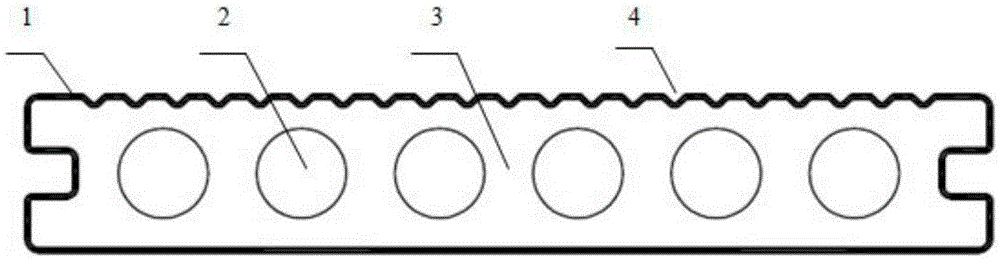

[0023] A flame-retardant polyolefin wood-plastic co-extruded profile and a preparation method thereof, such as figure 1 As shown, including flame retardant layer 1 and core body 3, flame retardant layer 1 is made of the following raw materials by weight percentage: plastic 57, wood flour 15, polyolefin flame retardant 20, polyethylene coupling agent 2, stearic acid And compound lubricant 2.4, compound phosphite antioxidant 0.2, hindered amine light stabilizer and ultraviolet absorber 0.4, inorganic pigment 3.

[0024] The core body 3 is made of the following raw materials in percentage by weight: wood powder 62, high-density polyethylene particles 30, stearic acid and composite lubricant 3, polyethylene coupling agent 2, and inorganic pigment 3.

[0025] The core body 3 and the flame-retardant layer 1 are formed by co-extrusion process at one time, and the steps are as follows: A, raw material preparation; B, feeding and mixing materials; C, granulation; D, extrusion molding; ...

Embodiment 2

[0035] A flame-retardant polyolefin wood-plastic co-extrusion profile and its preparation method, the core body 3 and the flame-retardant layer 1 are formed by a co-extrusion process, and the steps are as follows: A, raw material preparation; B, feeding and mixing materials; C, granulation ; D, extrusion molding; E, cooling and setting; F, cutting.

[0036] A, raw material preparation: core body 3 is prepared by the following raw materials by weight percentage: 50 of wood powder, 37 of plastic, 5 of stearic acid and compound lubricant, 3 of polyethylene coupling agent, and 5 of inorganic pigment are weighed respectively Quantity, the plastic is high-density polyethylene particles; the flame retardant layer is prepared according to the following raw materials in weight percentage: plastic is 30, wood powder is 30, environmental protection polyolefin flame retardant is 30, polyethylene coupling agent is 3, stearic acid And the compound lubricant is 5, the antioxidant is 0.4, the...

Embodiment 3

[0045] A flame-retardant polyolefin wood-plastic co-extruded profile and a preparation method thereof, such as figure 1 As shown, the core body 3 and the flame retardant layer 1 are formed by co-extrusion process at one time, and the steps are as follows: A, raw material preparation; B, feeding and mixing materials; C, granulation; D, extrusion molding; E, cooling and setting; F , cutting.

[0046] A, raw material preparation: the core body 3 is prepared by the following raw materials by weight percentage: the wood powder is 70, the plastic is 27, stearic acid and compound lubricant are 1, polyethylene coupling agent is 1, and inorganic pigment is 1 respectively. Weighing, the plastic is high-density polyethylene particles; the flame-retardant layer is prepared by the following raw materials in weight percentage: the plastic is 80, the environmentally friendly polyolefin flame retardant is 12.7, the polyethylene coupling agent is 1, stearic acid and compound lubricant 1 for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com