Manufacturing method of PTFE (polytetrafluoroethylene) fabric self-lubricating spherical plain bearing

A technology of joint bearings and PTFE, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of curing failure, wear resistance and bonding strength decline, and low processing efficiency, and achieve excellent strength and wear resistance , Improve performance and life, and increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

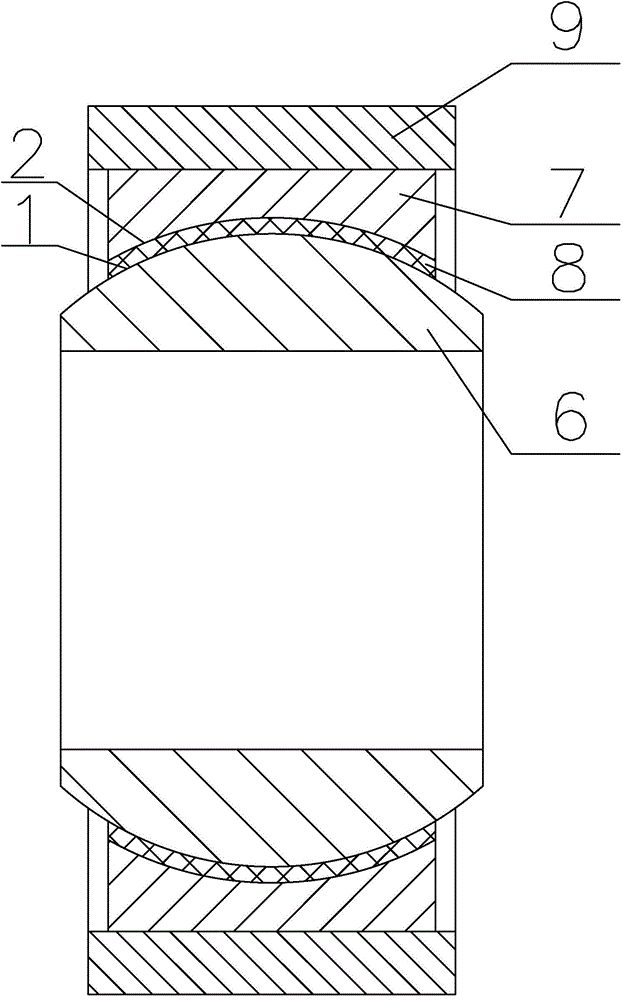

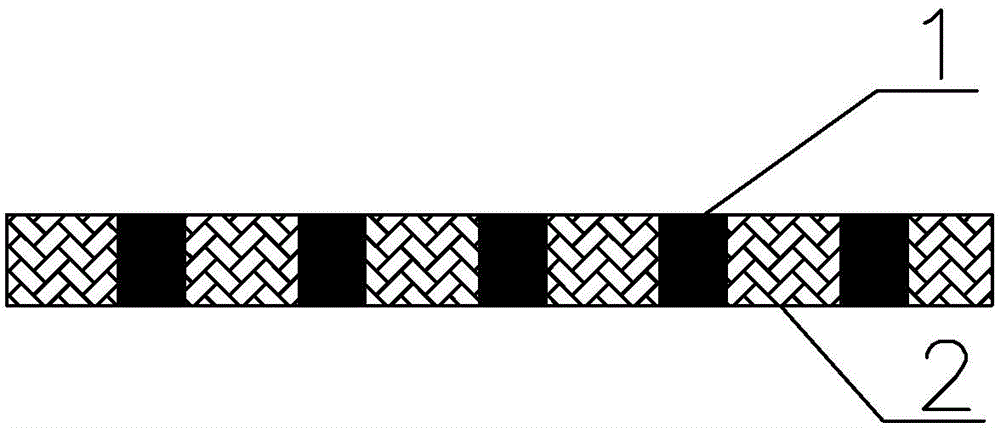

[0035] Choose a self-lubricating joint bearing with an inner diameter of 30 mm, an outer diameter of 47 mm, an inner ring width of 22 mm, and an outer ring width of 18 mm. The thickness of the PTFE fabric liner 8 is 0.58 mm;

[0036] Colloid A is coated on the friction surface 1 of the PTFE fabric liner 8;

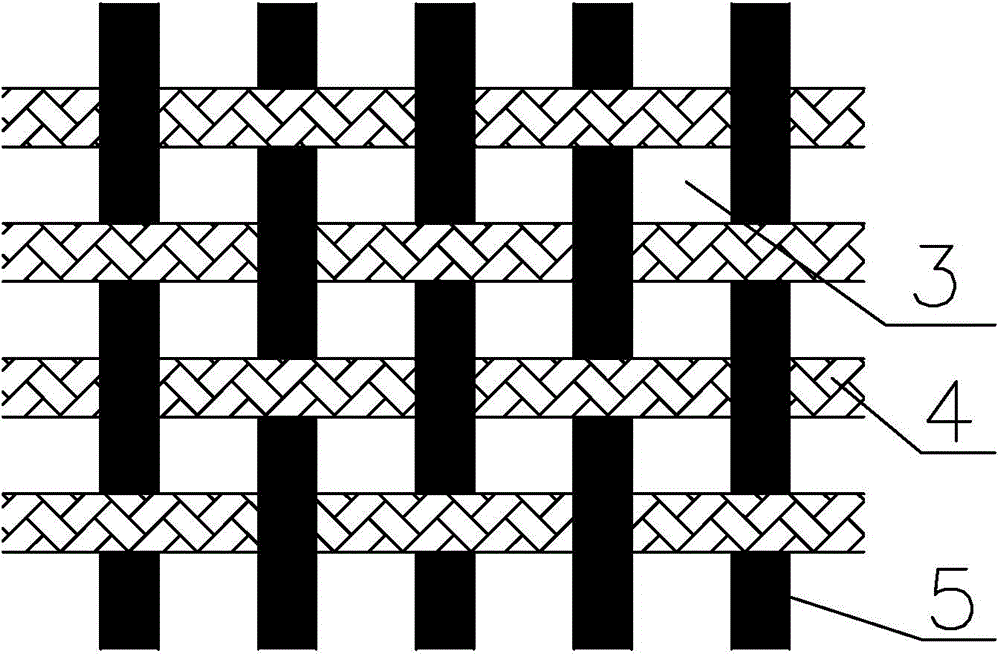

[0037] The PTFE fabric liner 8 coated with colloid A is rolled, and the colloid A is pressed into the warp 5 of the PTFE fabric liner 8 and the intersecting gap 3 of the weft 4, and the thickness range of the PTFE fabric liner 8 is accurately controlled as 0.68±0.02mm;

[0038] The fabric liner is cured by flat hot pressing technology, so that the friction surface 1 is not sticky: a piece of release paper is placed on the friction surface 1 and the sticking surface 2 of the PTFE fabric liner 8 respectively, and placed between two flat workpieces , use a press to apply a pressure of 0.5MPa, cover the pressure part of the press with an oven to cure the PTFE fabric liner 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com