Rotatable pressing mould base

A technology for pressing molds and rotating shafts, which is applied in the direction of molds and forming indenters, which can solve the problems of weakening the compressive strength of the stamping seat, increasing the manufacturing cost of the stamping seat, and affecting the quality of refractory brick forming, so as to reduce the manufacturing cost and simplify the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

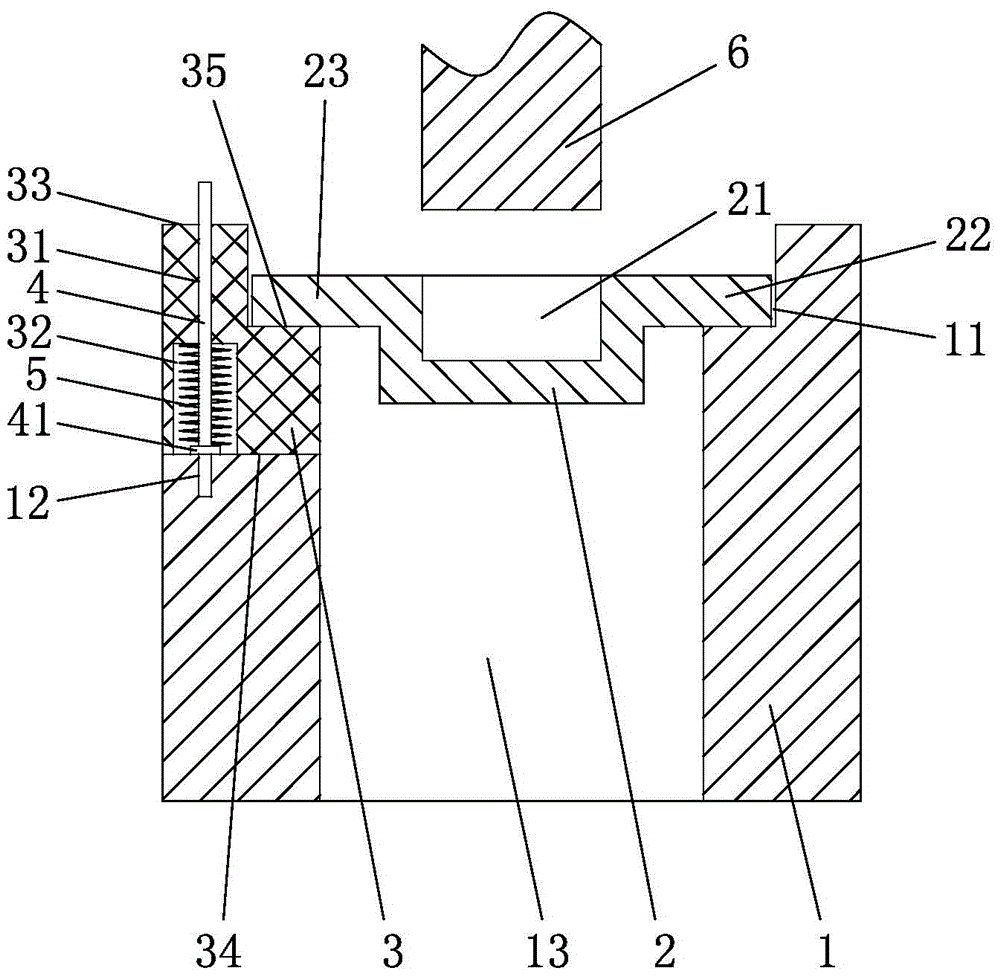

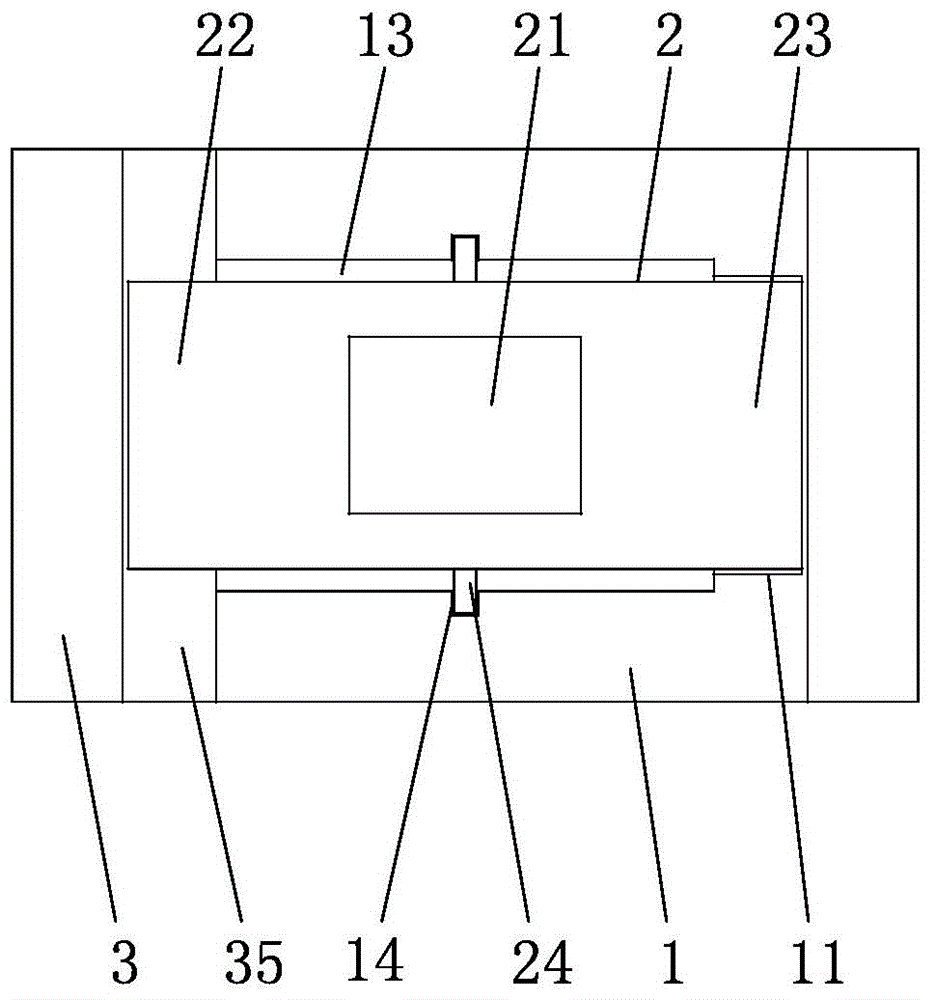

[0016] refer to figure 1 and figure 2 , a rotatable pressing mold base, including a stamping base 2 and a fixed assembly, the stamping base 2 is provided with a forming groove 21, and the side walls of the front and rear sides of the stamping base 2 are respectively provided with outwardly protruding rotating shafts 24, stamping The right end of the seat 2 is provided with a first connecting block 22 , and the left end of the stamping seat 2 is provided with a second connecting block 23 . The fixed assembly includes a fixed block body 1 and a step block 3. The fixed block body 1 is provided with a card slot 11, a discharge channel 13 and a positioning groove 14. After the step block 3 is fastened on the fixed block body 1, the top of the step block 3 The surface 33 is flush with the top surface of the fixed block body 1, the step surface 35 on the step block 3 is flush with the bottom wall of the slot 11, the first connecting block 22 is inserted into the slot 11, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com