Ore selection method for treating tin, lead and zinc polymetallic oxidized ore

A technology of polymetallic oxide ore and ore dressing method, which is applied in flotation, solid separation, etc., can solve the problems of high cost and inapplicability, and achieve the effects of improving grade, easy control and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

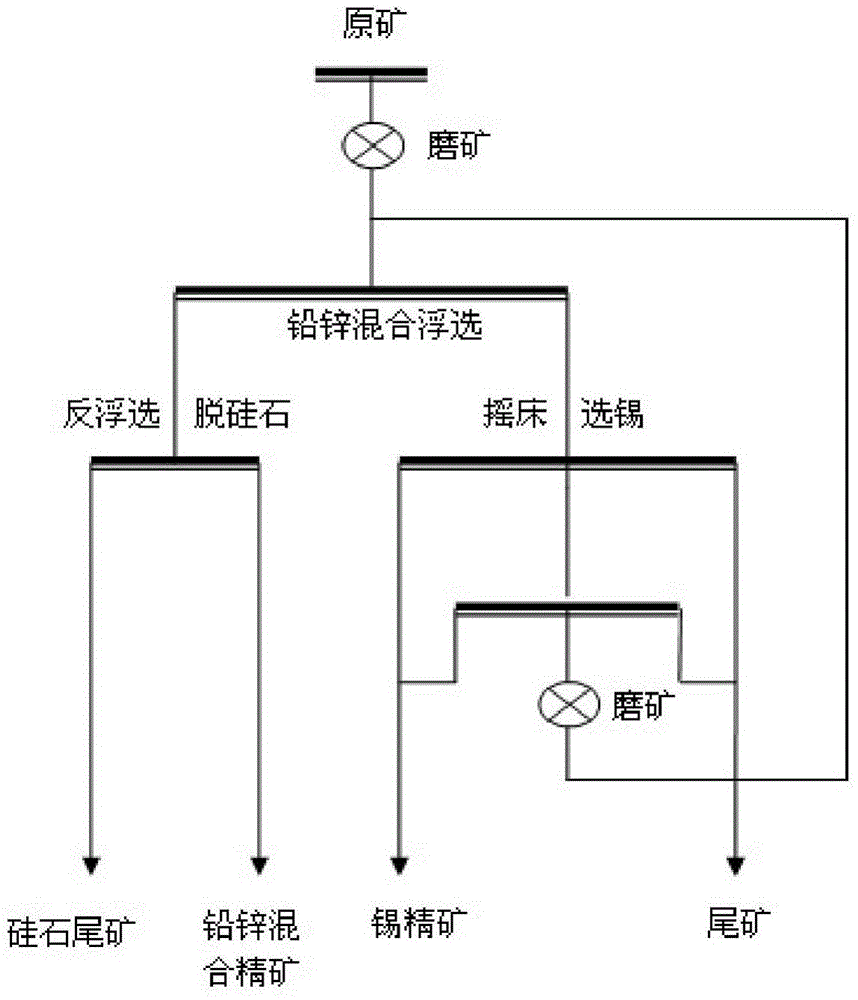

Image

Examples

Embodiment 1

[0029] A beneficiation method for processing tin-lead-zinc polymetallic oxide ore, the raw ore composition of the processed low-grade tin-lead-zinc polymetallic oxide ore: 0.28% tin, 1.06% lead, 0.70% antimony, 78.2g / t silver, 5.52 g / t zinc %, indium 45.0g / t.

[0030] Above-mentioned raw ore is passed through following processing steps:

[0031] (1) Crush the raw ore and grind it to -200 mesh about 75%;

[0032] (2) The grinding and grading products are directly subjected to lead-zinc oxide mixed flotation without desliming, the feeding concentration is about 30%, the dosage of sodium sulfide is 2600g / t, the dosage of butyl xanthate is 120g / t, and the dosage of mixed amine is 250g / t , the flotation process is first coarse, second fine and second sweeping; all the minerals that can float up will all enter the foam product; the products in the flotation tank will be re-selected on a shaking table to obtain tin concentrate, a middle ore and tailings; Tin concentrate, middle ore...

Embodiment 2

[0039]A beneficiation method for treating tin-lead-zinc polymetallic oxide ore, the raw ore composition of low-grade tin-lead-zinc polymetallic oxide ore: 0.52% tin, 1.26% lead, 0.61% antimony, 81.4g / t silver, 4.05% zinc %, indium 48.0g / t.

[0040] Above-mentioned raw ore is passed through following processing steps:

[0041] (1) Crushing the raw ore and grinding it to -200 mesh about 80%;

[0042] (2) The ore grinding and grading products are directly subjected to mixed flotation of lead and zinc oxide without desliming, the feeding concentration is about 35%, the dosage of sodium sulfide is 2200g / t, the dosage of ethyl xanthate is 100g / t, and the dosage of stearylamine is 220g / t, the flotation process is firstly coarse, secondly refined and secondly swept; all the minerals that can be floated will all enter the foam product; the products in the flotation tank will be re-selected on a shaking table to obtain tin concentrate, a middle ore and tailings; The ore is re-selecte...

Embodiment 3

[0049] A beneficiation method for processing tin-lead-zinc polymetallic oxide ore, the raw ore composition of the processed low-grade tin-lead-zinc polymetallic oxide ore: 0.64% tin, 2.61% lead, 1.65% antimony, 76.4g / t silver, 9.72% zinc %, indium 43.2g / t.

[0050] Above-mentioned raw ore is passed through following processing steps:

[0051] (1) Crushing the raw ore and grinding it to -200 mesh about 80%;

[0052] (2) The ore grinding and grading products are directly subjected to mixed flotation of lead and zinc oxide without desliming, the feeding concentration is about 25%, the dosage of sodium sulfide is 3000g / t, the dosage of butyl xanthate is 100g / t, and the dosage of butyl ammonium black is used for medicine 50g / t of mixed amine, 400g / t of mixed amine, 30~50 g / t of terpineol oil, the flotation process is firstly coarse, secondly refined and secondly swept; Bed re-election to obtain tin concentrate, first-stage middling and tailings; put the first-stage middling to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com