Composite FRP Crusher

A crusher, fiberglass technology, applied in the direction of mechanical material recovery, recycling technology, grain processing, etc., can solve problems such as sticking together or on the crushing mechanism, lack of crushing equipment, and hindering the smooth progress of the crushing process, so as to achieve unsatisfactory Easy to stick to knives, high crushing efficiency, and prevent the adhesion of glass fiber reinforced plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The main shaft 5 is vertically installed in the center of the crusher through the bearing 4, the chain 8 and the cutter head hammer assembly 7 are fixed on the same main shaft 5, the motor 1 drives the main shaft 5 to rotate through the transmission mechanism 2, and then drives the chain 8 And the movement of the cutter head hammer head assembly 7 strikes and breaks the material. The motor speed and main shaft speed can be adjusted according to the needs, and since the same rotating shaft is shared, the two-stage crushing process will be carried out at the same time.

[0017] The material to be crushed enters the upper crushing cavity from the top, and after being crushed by the rotating chain, it enters the lower cavity 6 through the lower trough 9. The opening size of the lower trough 9 can be adjusted to control the output of the material and the output.

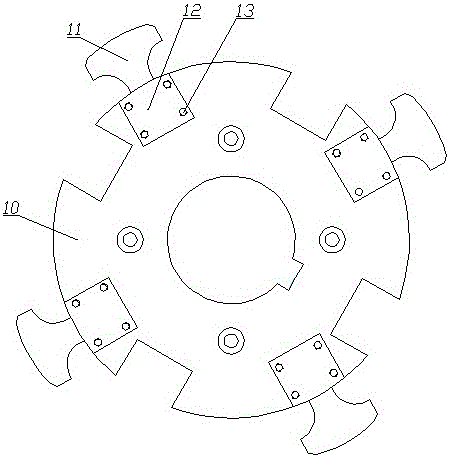

[0018] Inside the lower cavity 6 are multi-layer crushing cutterheads 10, the diameter of each lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com