Device for inoculating mushroom and black fungus sticks and inoculation method

A fungus stick inoculation, black fungus technology, applied in the directions of botanical equipment and methods, application, horticulture, etc., can solve the problems of slow inoculation speed, poor stability, unsuitable for large-scale production, etc., and achieves high and stable inoculation yield. Avoid the effects of slow inoculation speed and controllable inoculation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

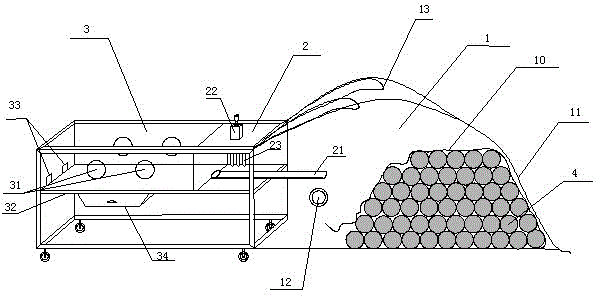

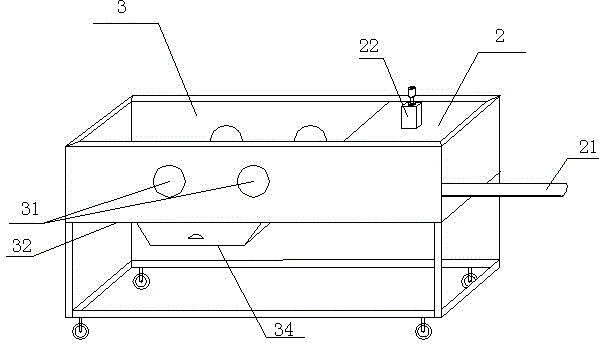

[0028] The present invention is mainly made up of two box bodies and the thin-film bacterial stick room 1 that film covers, and a box body is the inoculation room 3, promptly connects the strain room, and another box body is the bacteria stick punching room 2, and the inoculation room 3 and the bacterium stick punching chamber 2 can be provided with a dividing plate, at this time, one or two holes are set on the dividing plate, which communicate with the bacterium stick conveying groove 21, the inoculation chamber 3 and the bacterium stick punching chamber 2 It is also possible to combine the two chambers into one, that is, no partition is set in the middle.

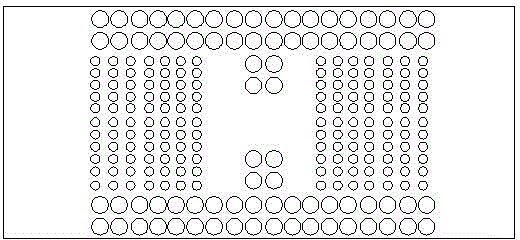

[0029] The film bacteria stick chamber 1 is made of film covering and sealing, which includes two layers, namely the inner film 10 and the outer film 11. The inner film 10 wraps the whole pile of bacteria sticks to form a closed space in which an aerosol disinfectant is placed; Located on the outside of the inner membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com