small combine harvester

A combine harvester, small-scale technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of the strength of the output shaft of the shell, the stroke cannot meet the requirements, and the braking device is easy to fail, etc., so as to achieve easy handling , simple structure, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

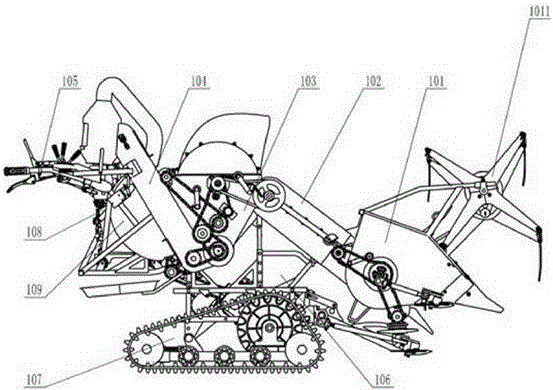

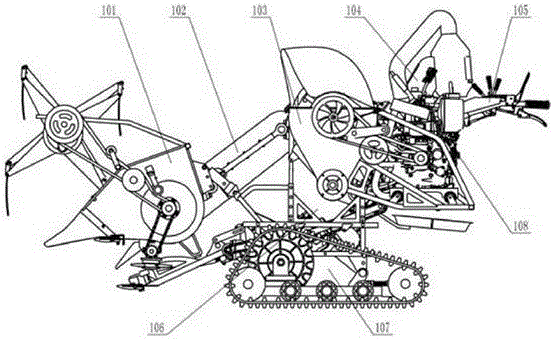

[0037] see Figure 1 to Figure 2, a small combine harvester, including a header device 101, an intermediate transmission device 102, a threshing device 103, a grain delivery device 104, a manipulation device 105, a lifting device 106, a walking device 107, a grain cleaning device 109, and a power device 108. Header device 101 comprises reel 1011, and is connected with intermediate transmission device 102, and intermediate transmission device 102 is connected with threshing device 103, and threshing device 103 is connected with grain delivery device 104, and grain delivery device 104 is connected with clearing grain device 109, clearing The grain device 109 is connected with the operating device 105 and the power device 108, and the above-mentioned devices are installed on the lifting device 106, and the walking device 107 is installed at the bottom of the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com