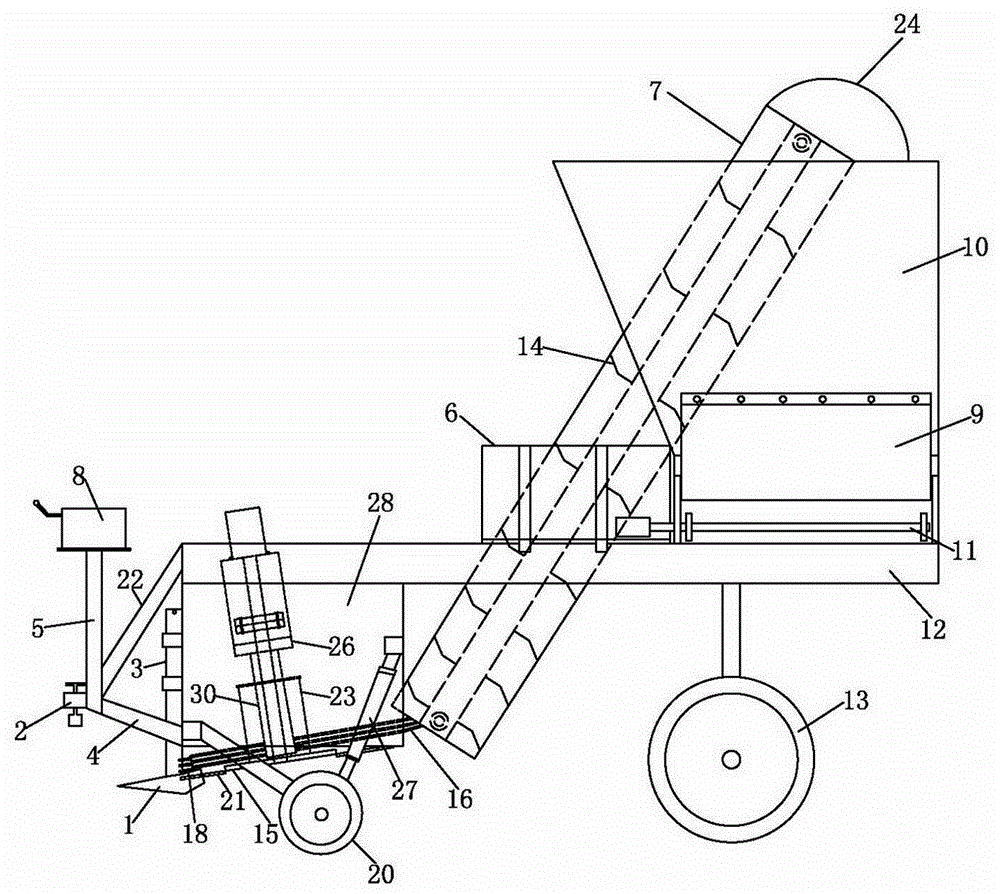

Beet digging-picking harvester

A harvester and sugar beet technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of low work efficiency, high labor intensity, time-consuming and labor-intensive, etc., and achieves high work efficiency and less sugar beet waste. , Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

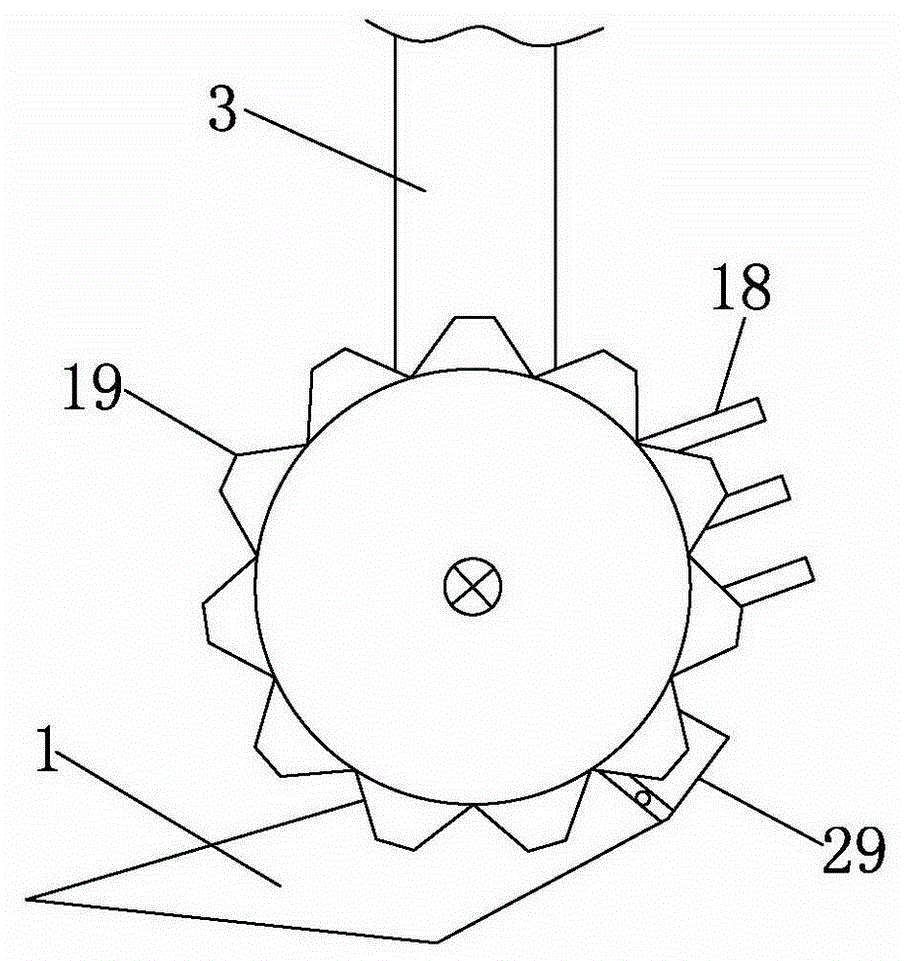

[0015] Embodiment 1, sugar beet excavation picks up harvester, comprises frame 12, spacer wheel 20, road wheel 13 and is arranged on the universal traction frame 2 of frame 12 front ends, and described universal traction frame 2 is consolidated on frame 12 The joint of the front bar 4 and the upper rod 22 protruding out from the lower and upper sides of the front end is provided with a vertical bar 5 on the joint, and an operating console 8 is arranged on the vertical bar 5, and the adjustment bar is locked by buckling at the front end of the frame 12. 3 is connected on the horizontal bracket 25 of the frame 12, the pick-up plow 1 is arranged at the lower end of the adjustment rod 3, and the guide rod 18 is stretched out to the rear of the frame on the adjustment rod 3 above the pick-up plow 1; 12. A rectangular reinforced wall 28 is fixedly arranged on the front outer wall, and a fixed cross bar 26 is arranged on the inner side of the reinforced wall 28, and a rotating shaft i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com