Slurry for coating isolating membrane of lithium ion battery, isolating membrane and preparation method of slurry

A lithium-ion battery and separator technology, which is used in secondary batteries, starch coatings, battery pack components, etc. Insufficient and other problems, to achieve the effect of strong high and low temperature tolerance, uniform thickness and uniform electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also provides a method for preparing the coating slurry of the separator of the lithium-ion battery with both high and low temperature, comprising the following steps:

[0023] Step 1: Mix the above-mentioned components according to the ratio of each weight percentage, and carry out planetary stirring at a speed of 80-120 RPM for 20-40 minutes.

[0024] Step 2: A high-power ultrasonic device (Guangzhou Xindongli NP8000) disperses the slurry, the power is 800-1200W, and the ultrasonic dispersion time is more than 10 minutes, that is, the coating of the separator film of the lithium-ion battery with both high and low temperature is obtained slurry.

[0025] Using the above stirring and dispersing methods and stirring parameters can improve the stirring efficiency and effectively solve the phenomenon of molecular agglomeration of the slurry.

[0026] The present invention also provides a high and low temperature separator for lithium ion batteries, i...

Embodiment 1

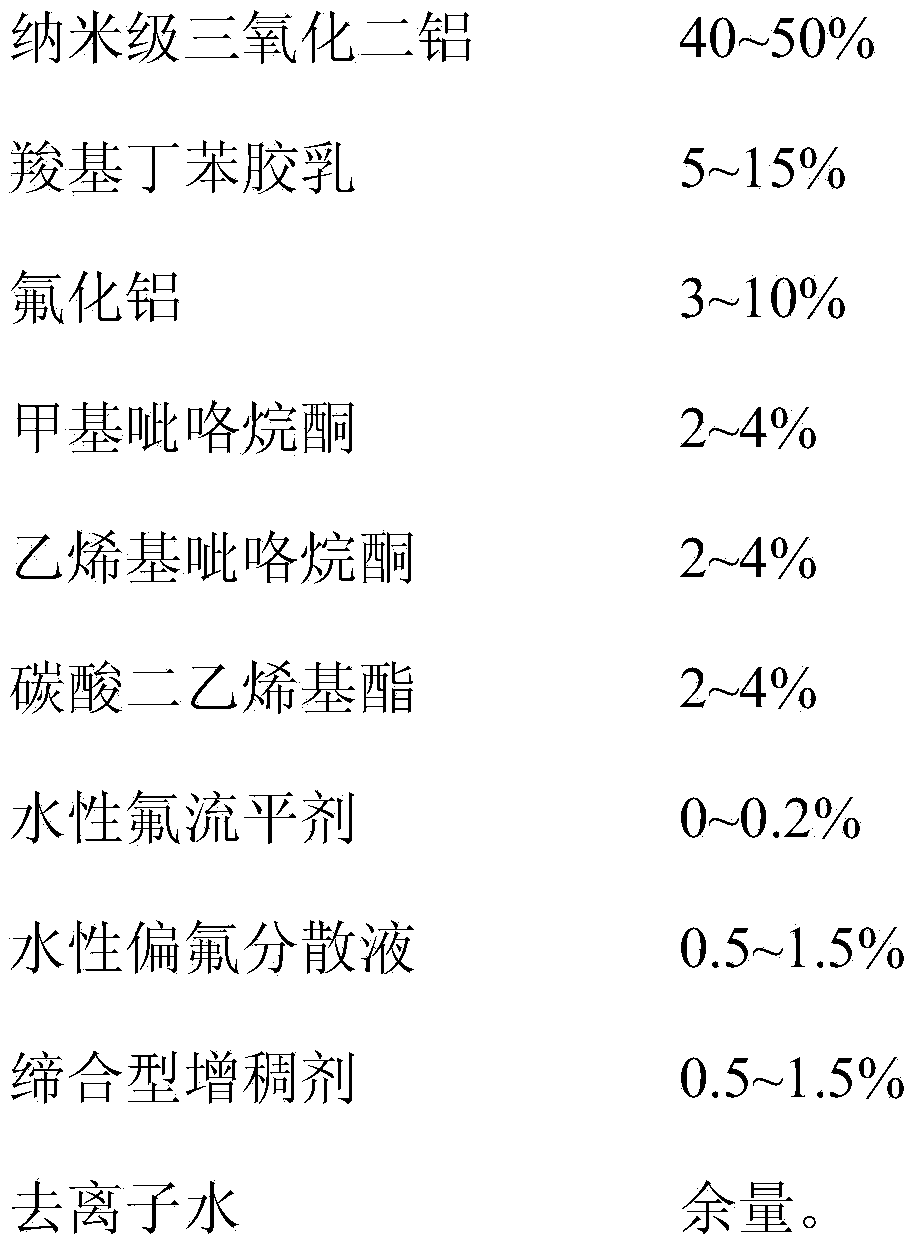

[0030] This embodiment provides a coating slurry for a separator of a lithium-ion battery with both high and low temperature, including the following components in weight percentage:

[0031]

[0032]

[0033] The water-based fluorine leveling agent is DuPont FS-3100, a fluorosurfactant.

[0034] The aqueous fluoride dispersion is DuPont FSWET1010, a fluorine wetting and leveling agent.

[0035] The associative thickener is Clariant thickener associative TK530.

[0036] The present invention also provides a method for preparing the coating slurry of the separator of the lithium-ion battery with both high and low temperature, comprising the following steps:

[0037] Step 1: Weigh 45kg of nano-scale aluminum oxide, 10kg of carboxylated styrene-butadiene latex, 5kg of aluminum fluoride, 3kg of methylpyrrolidone, 3kg of vinylpyrrolidone, 3kg of divinyl carbonate, 0.1kg of fluorine Surfactant DuPont FS-3100, 1kg fluorine wetting and leveling agent DuPont FSWET1010, 1kg Clar...

Embodiment 2

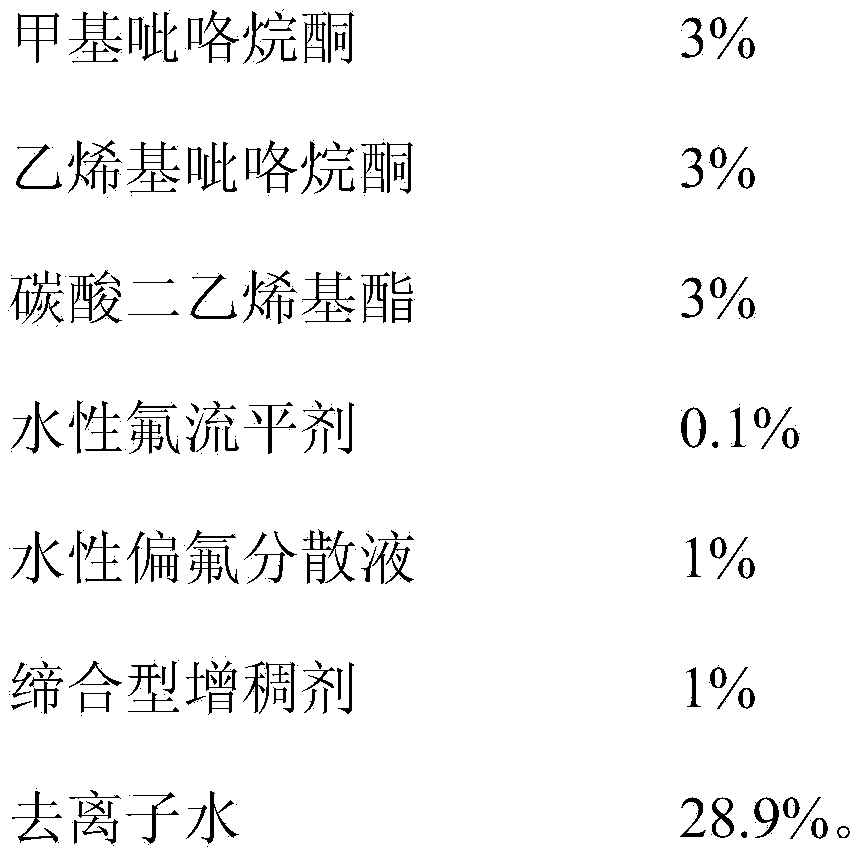

[0048] This embodiment provides a coating slurry for a separator of a lithium-ion battery with both high and low temperature, including the following components in weight percentage:

[0049]

[0050]

[0051] The water-based fluorine leveling agent is DuPont FS-3100, a fluorosurfactant.

[0052] The aqueous fluoride dispersion is DuPont FSWET1010, a fluorine wetting and leveling agent.

[0053] The associative thickener is Clariant thickener associative TK530.

[0054] The present invention also provides a method for preparing the coating slurry of the separator of the lithium-ion battery with both high and low temperature, comprising the following steps:

[0055] Step 1: Weigh 50kg of nano-sized aluminum oxide, 5kg of carboxylated styrene-butadiene latex, 8kg of aluminum fluoride, 2kg of methylpyrrolidone, 2kg of vinylpyrrolidone, 4kg of divinyl carbonate, 0.2kg of fluorine Surfactant DuPont FS-3100, 0.5kg fluorine wetting and leveling agent DuPont FSWET1010, 1.5kg C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com