Method for manufacturing hydrophobic component, hydrophobic component and photovoltaic device

A component and hydrophobic technology, applied in the field of nanomaterials, can solve problems such as affecting the hydrophobic performance of photovoltaic devices, poor hydrophobic performance of hydrophobic components, and small contact angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background art section, in the prior art, the low surface energy coating is directly formed on the smooth surface of the substrate with fewer hydroxyl groups, thus affecting the hydrophobicity of the low surface energy coating.

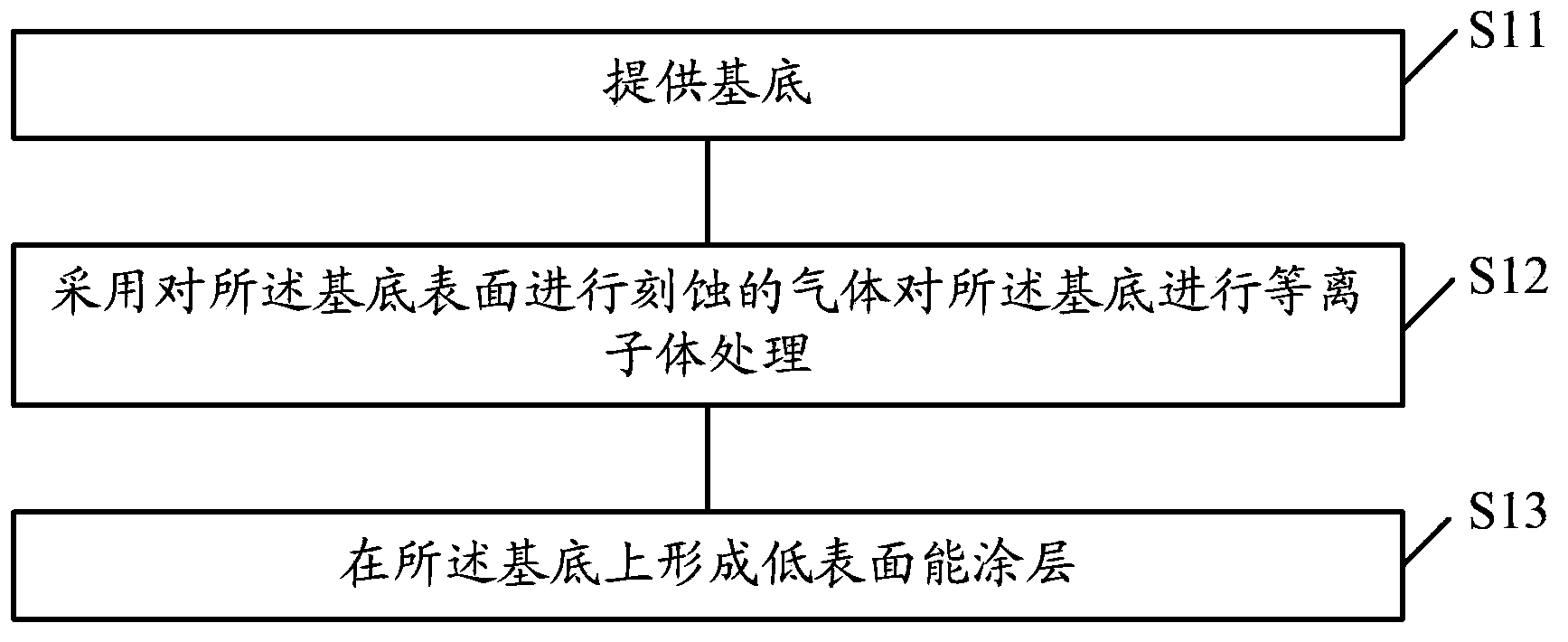

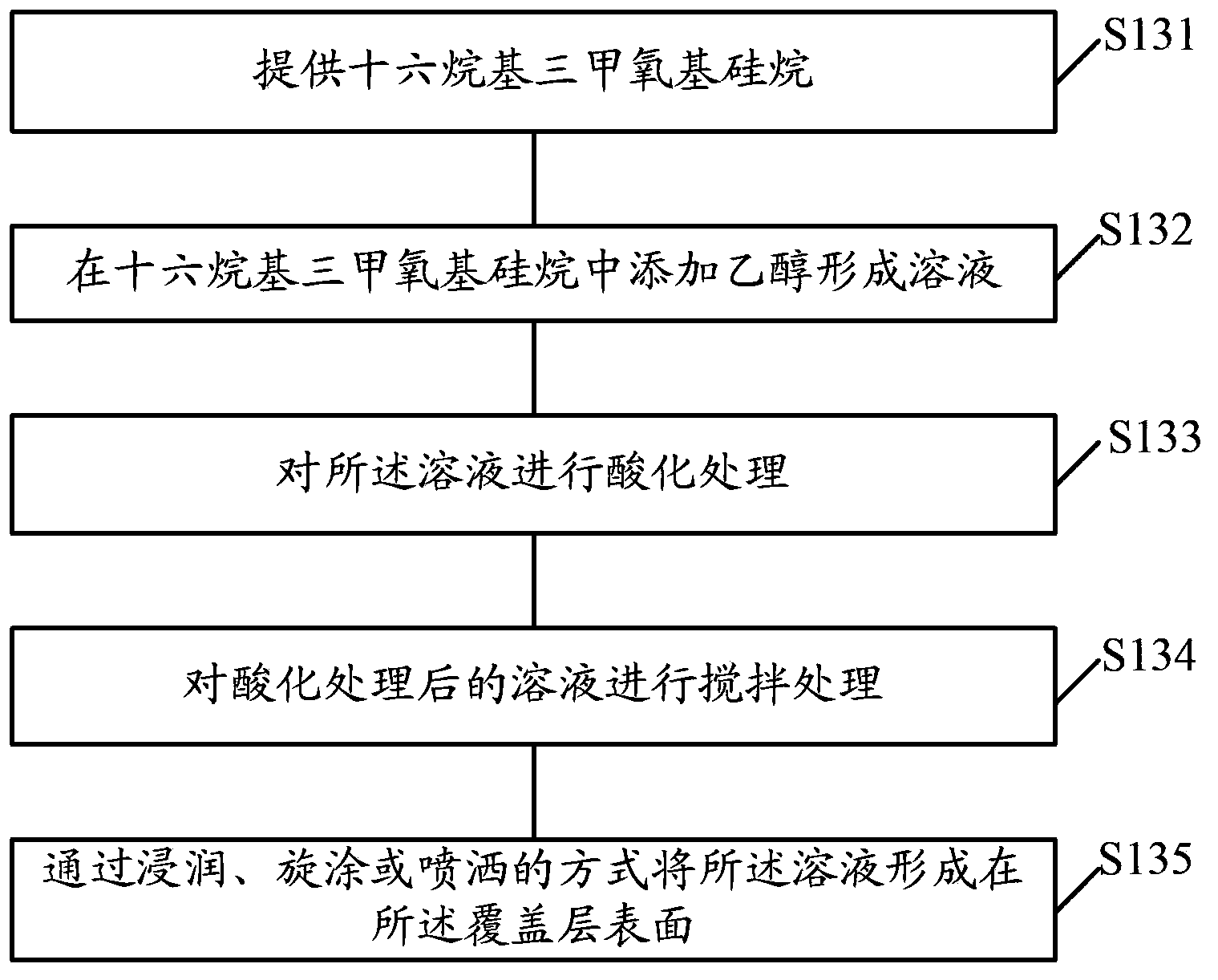

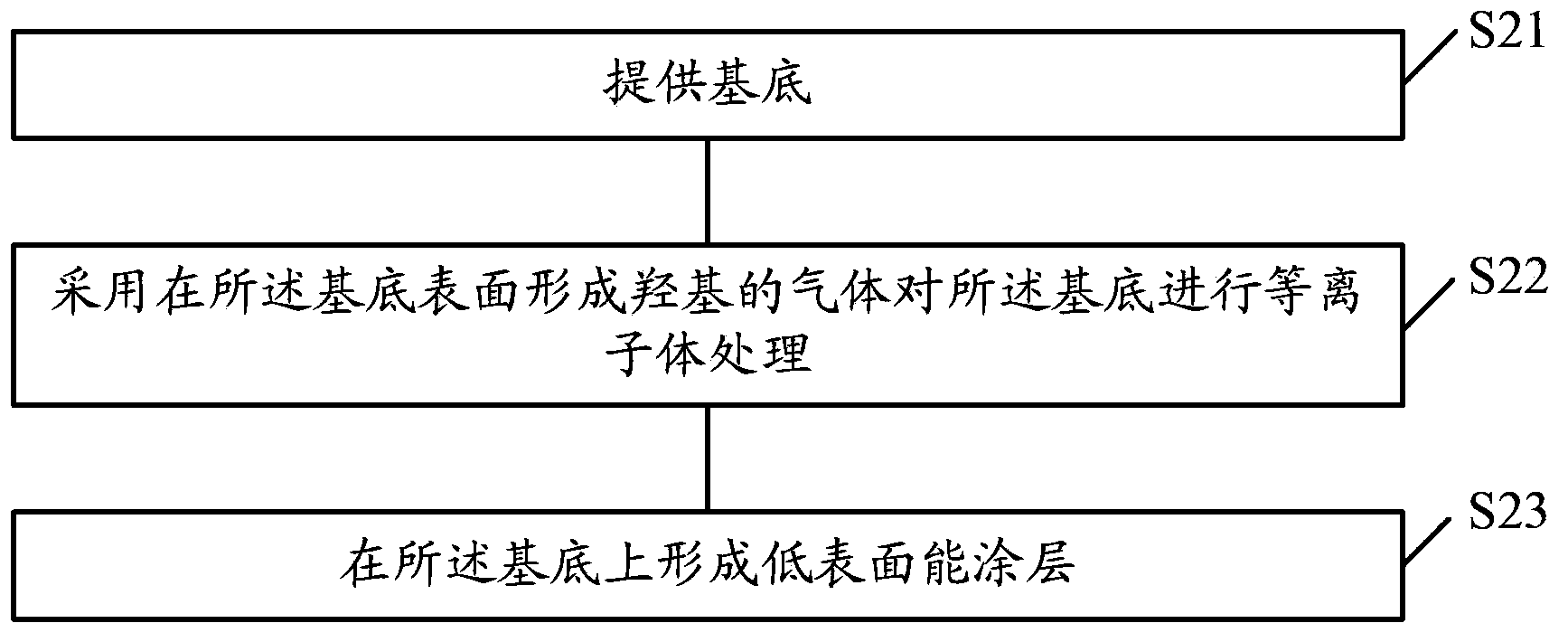

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] In view of the above problems, the inventors have found through research that when the low surface energy coating is formed on a substrate with a rough surface or a hydrophilic surface, the contact angle between the low surface energy coating and the substrate can be increased, thereby improving the hydrophobic performance. Further, the inventors have found that when performing plasma treatment on the surface of the substrate, by selecting an appropriate gas, the roughness of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com