Field stop type IGBT device with terminal structure and manufacturing method thereof

A technology of a terminal structure and a manufacturing method, applied in the field of IGBT devices, can solve problems such as increasing device switching loss, and achieve the effect of reducing the possibility of secondary breakdown and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with specific drawings and embodiments.

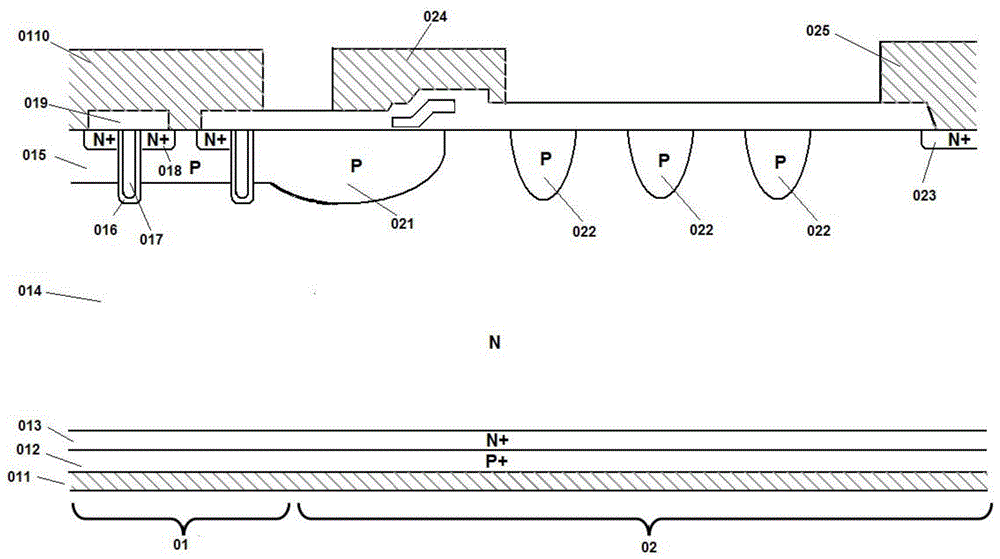

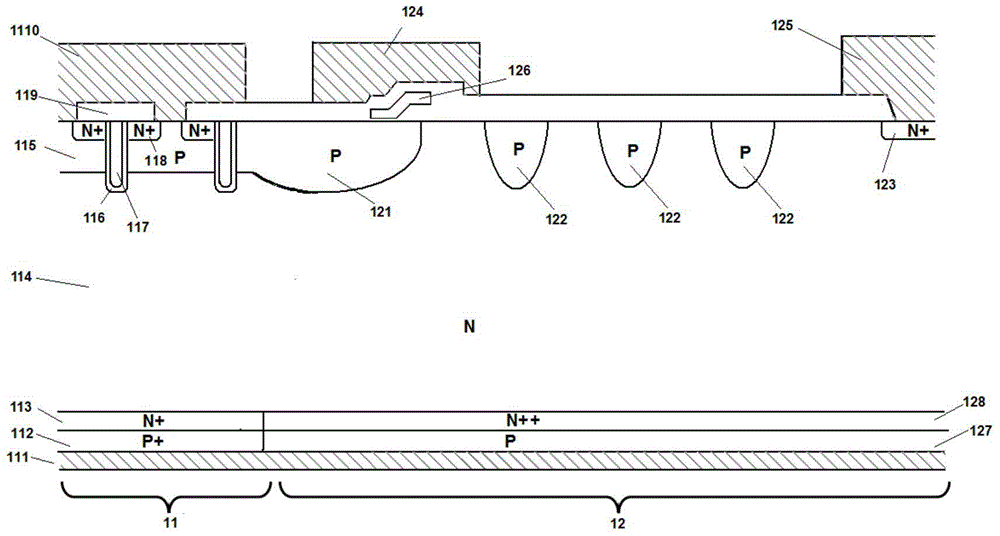

[0048] like Figure 2~Figure 10 As shown: Taking N-type field stop IGBT device as an example, the present invention includes cell region 11, terminal region 12, collector metal 111, P+ first collector region 112, N+ first buffer region 113, N-type drift region 114, P-type body region 115, gate oxide layer 116, polysilicon gate electrode 117, N+ emitter region 118, insulating dielectric layer 119, emitter metal 1110, P-type main junction 121, P-type voltage divider ring 122, N+ cut-off region 123 , gate lead-out metal 124 , cut-off metal 125 , polysilicon field plate 126 , P-type collector region 127 , N++ second buffer zone 128 , buffer mask layer 1111 and collector mask layer 1112 .

[0049] like figure 2 and Figure 10 As shown, on the top view plane of the field stop type IGBT device, it includes a cell region 11 and a terminal region 12 on the semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com