Shock absorption and adjustment mechanism of plane mirror

A technology of adjusting mechanism and plane mirror, applied in installation, optics, instruments, etc., can solve the problems of inability to meet use requirements, high cost, plane mirror deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

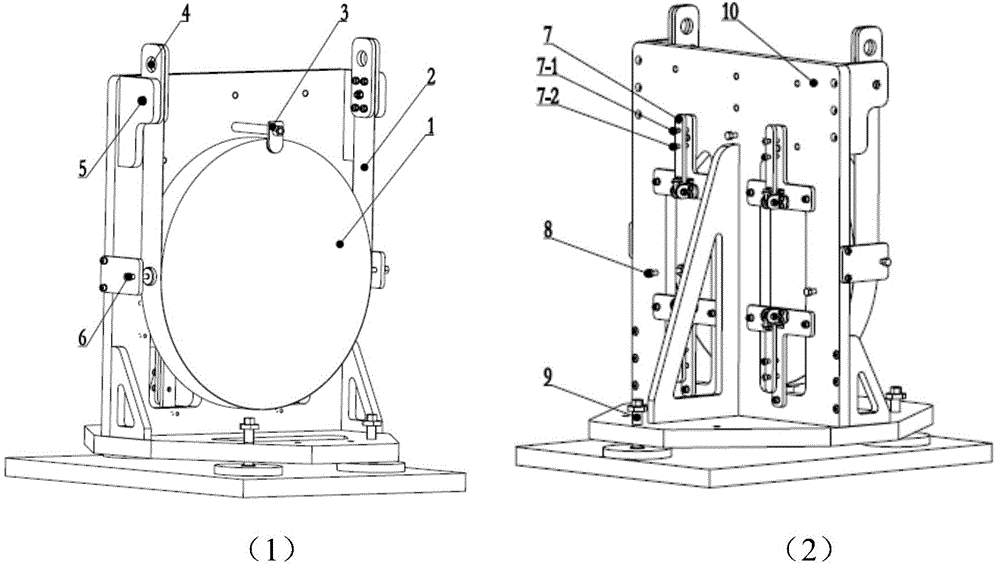

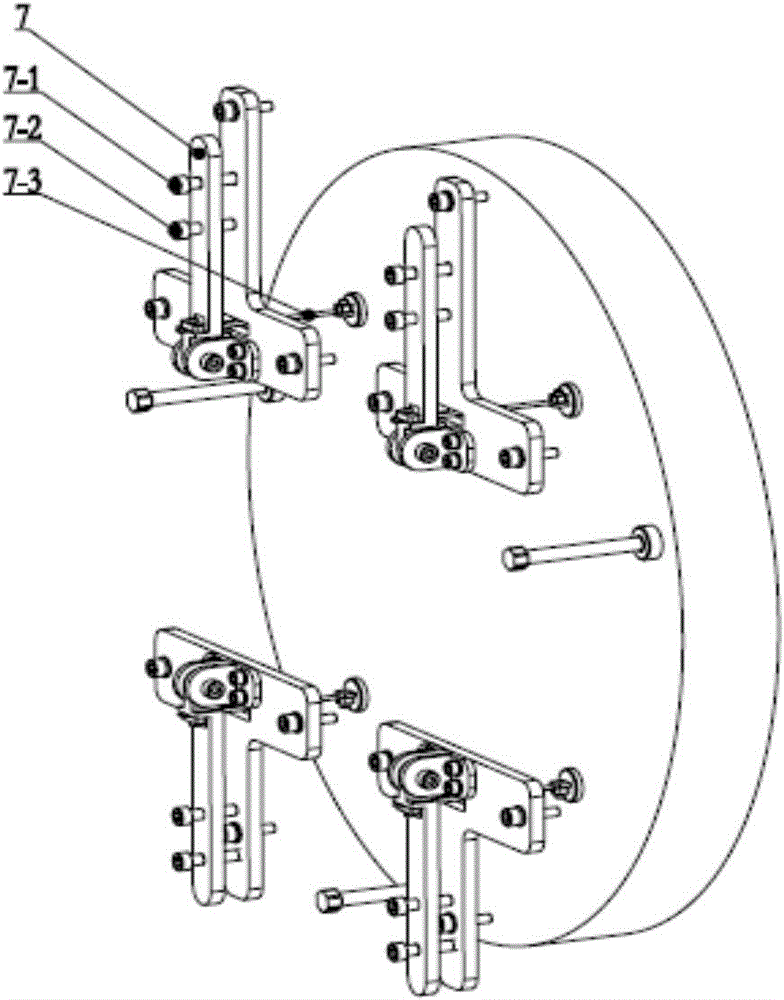

[0019] exist figure 1 In the embodiment shown, a microcrystalline flat mirror 1 with a diameter of 600 mm is placed on a thin steel strip 2 with a thickness of 0.5 mm, and is hung on the main structure 10 by a hanging block 4 and a half-threaded bolt 5 of M14, and the lateral thread adjustment is adjusted. The rod 6 is against both sides of the plane mirror 1, the loosening adjustment screw 7-1 and the tightening adjustment screw 7-2 are used in combination to make the tension steel belt 7-3 pull the plane mirror 1, and the back threaded adjustment rod 8 is adjusted to withstand the plane mirror 1, Adjust the bottom threaded adjustment rod 9 to realize the adjustment of the plane mirror 1 in the up and down and pitch directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com