A drying room of a rotary screen printing machine

A printing machine and drying room technology, applied to the general parts of printing machinery, printing machines, printing, etc., can solve the problems of fabric surface temperature field disorder, affecting economic benefits, poor drying degree of color paste, etc., and achieve a rapid and stable state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

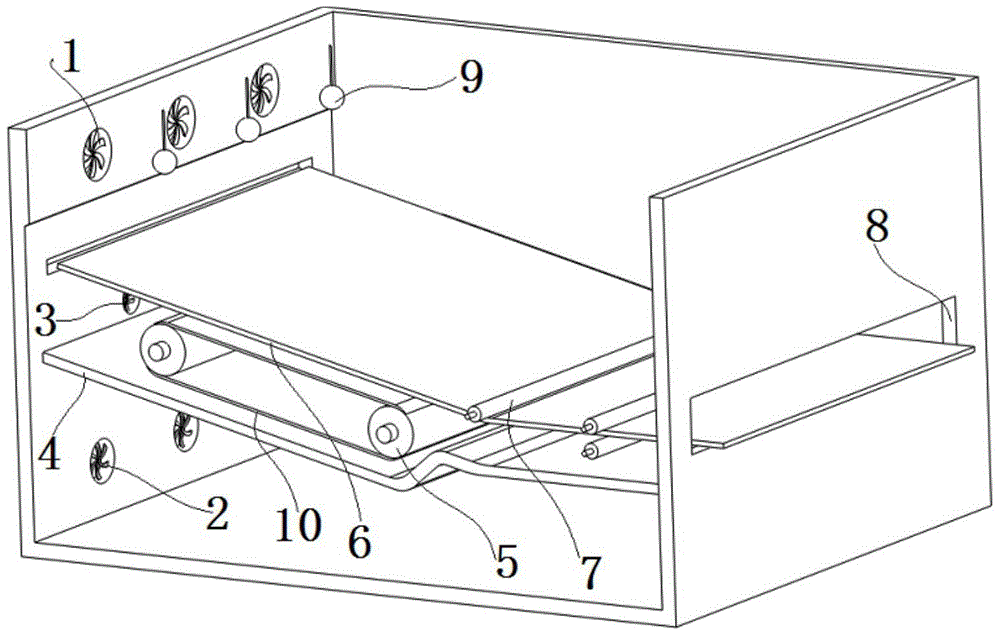

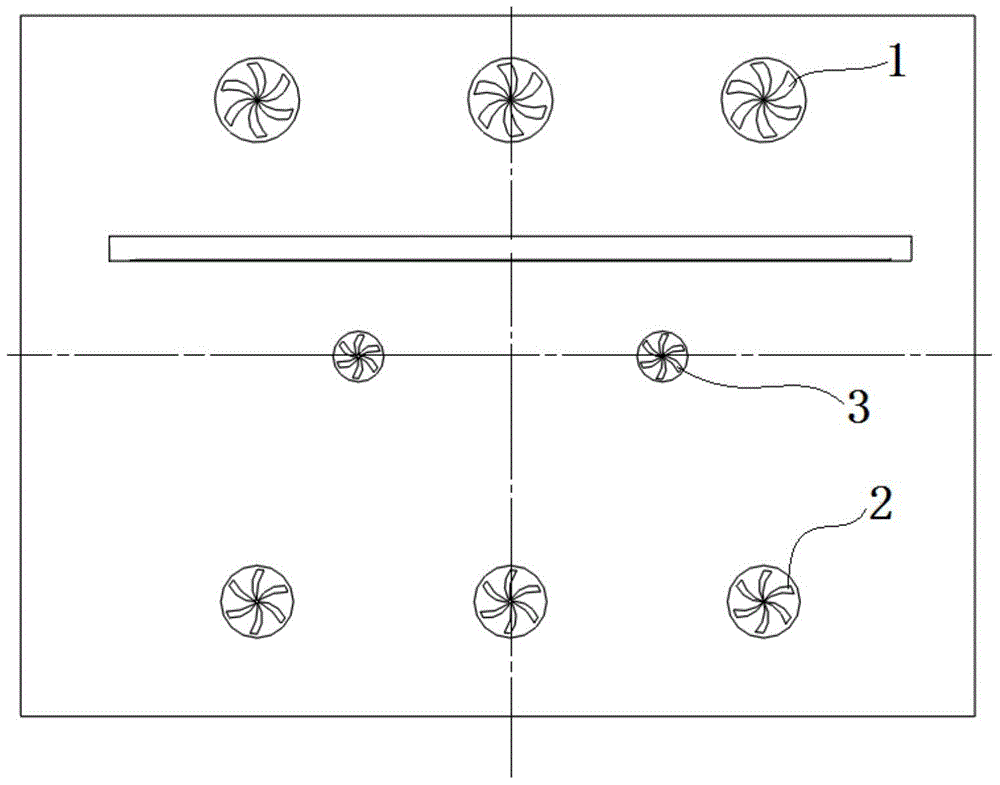

[0022] Such as figure 1 , figure 2 As shown, the drying room of the rotary screen printing machine of the present invention includes: three different types of blowers, the first blower 1, the second blower 2, the third blower 3 and the dividing plate 4, the belt guide roller 5, the pressure roller 7 , an air outlet 8, a heat source body 9, and a conduction belt 10, wherein the space of the drying room is divided into three areas A, B, and C by the fabric 6 and the partition plate 4, and the first fan 1 plays the role of blowing air and is located in the A area. The second fan 2 plays the role of air extraction and is located in area C. The third fan 3 plays the role of air extraction and is located in area B. The numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com