Direct evaporative passive self-cooling deflector

A deflector and evaporative technology, applied in the field of direct evaporative passive self-cooling deflectors, can solve the problems of reduced radiation heat transfer intensity, air deflectors without heat capacity and heat export capacity, etc., to increase cooling ability, promote natural ventilation, and reduce the effect of system thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

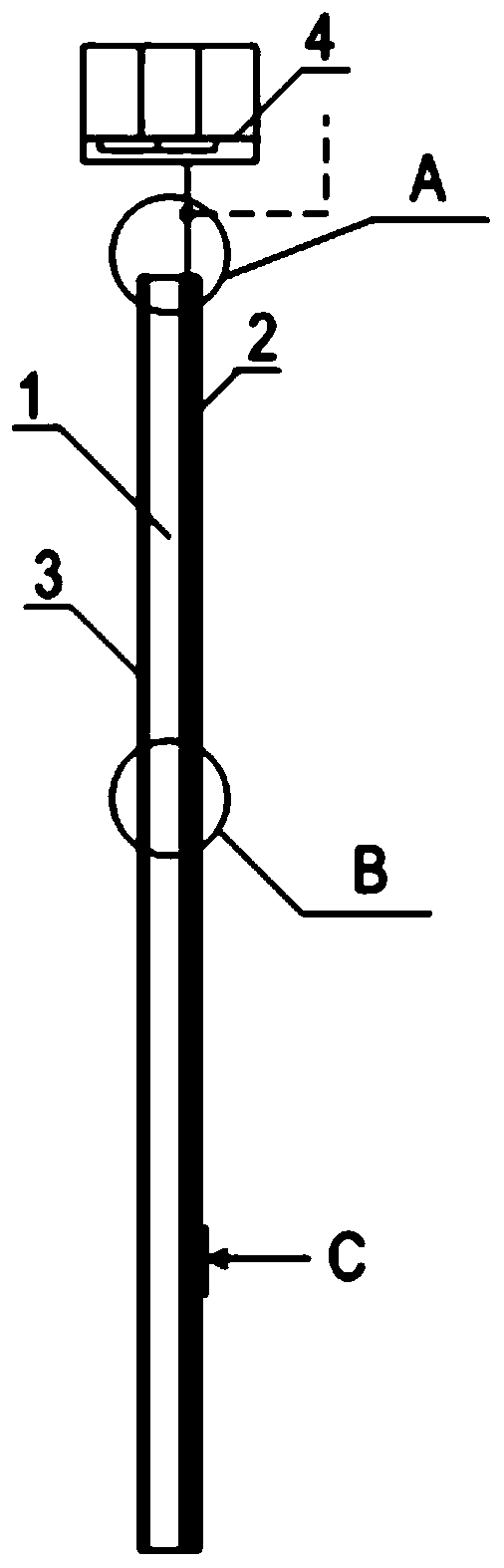

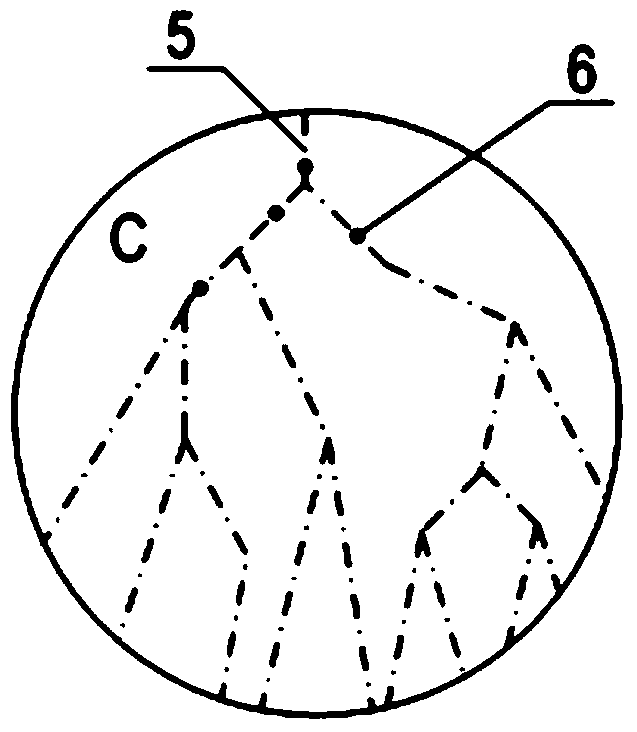

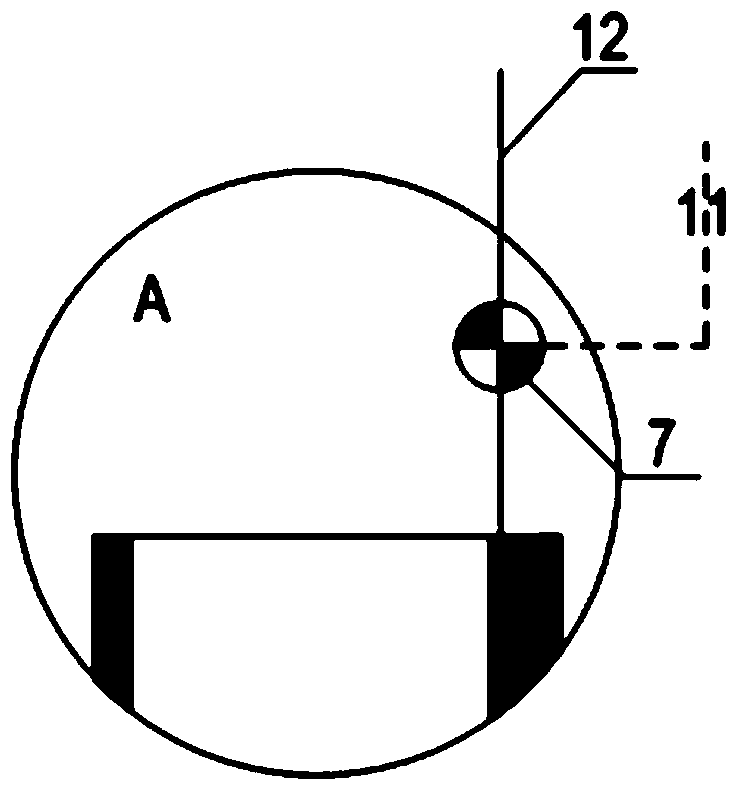

[0034] Such as Figure 1-3 Shown is a schematic structural view of the direct evaporative passive self-cooling deflector provided by the present invention. The deflector comprises a deflector structural skeleton 1 , one side of the deflector structural skeleton 1 is provided with a deflector porous material covering layer 2 , and the other side of the deflector structural skeleton 1 is covered with a deflector heat insulating layer 3 . A coolant channel 5 is provided on the frame 1 of the deflector structure, and the coolant channel 5 is a root-like structure, which is connected to the moisture-retaining coolant tank 4 of the deflector on the top of the containment through a coolant inlet pipeline 12 . The coolant channel 5 is provided with a coolant diffusion hole 6 for coolant distribution, and the coolant diffusion h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com