Novel spray type desulphurization dust removal boiler

A desulfurization dust removal and spray technology, which is applied in the field of boiler manufacturing, can solve the problems of large resistance, more smoke and sulfur dioxide, and poor natural ventilation in small vertical boilers, and achieves the effect of small resistance, fast dust removal, and good natural ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

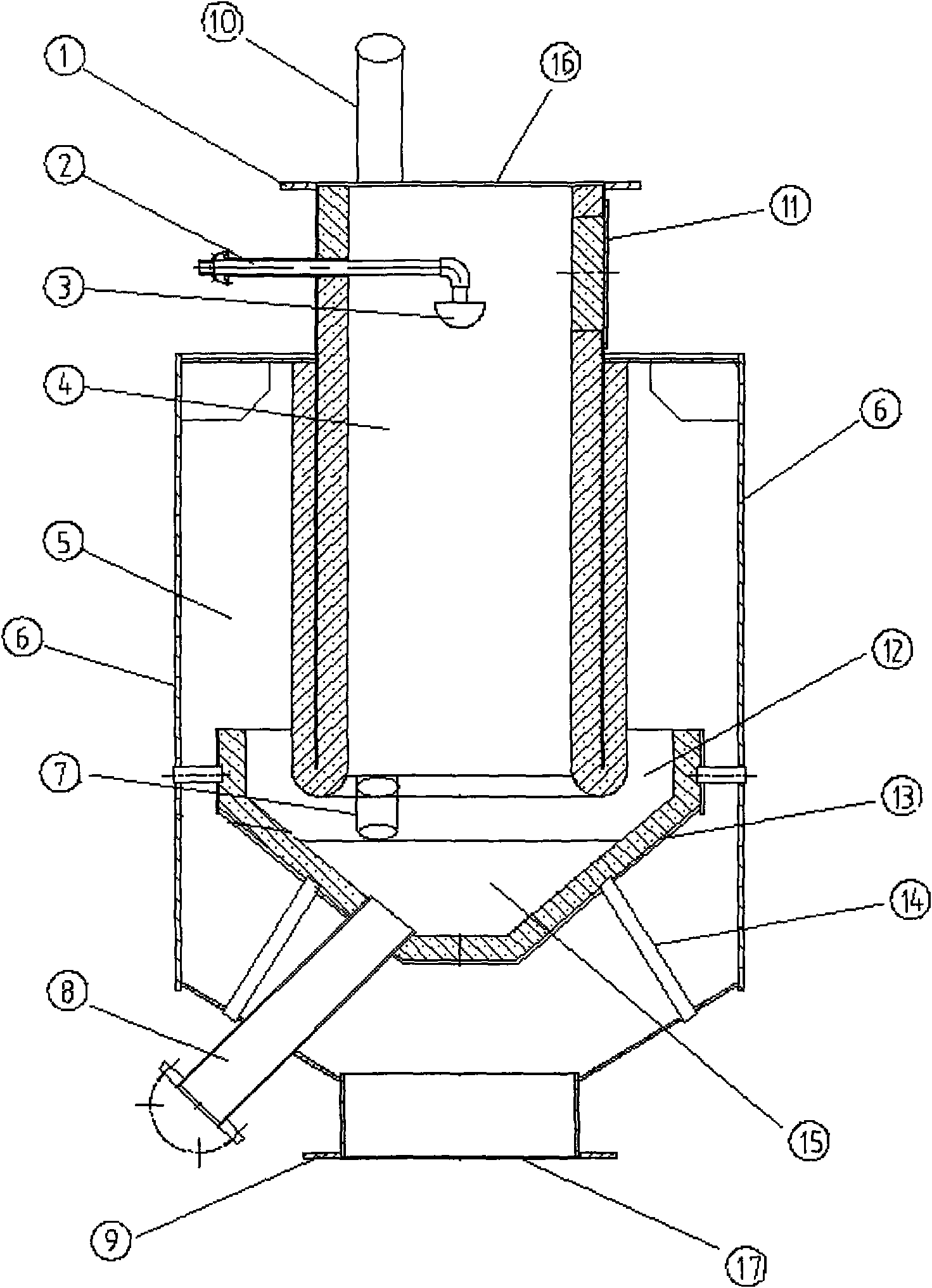

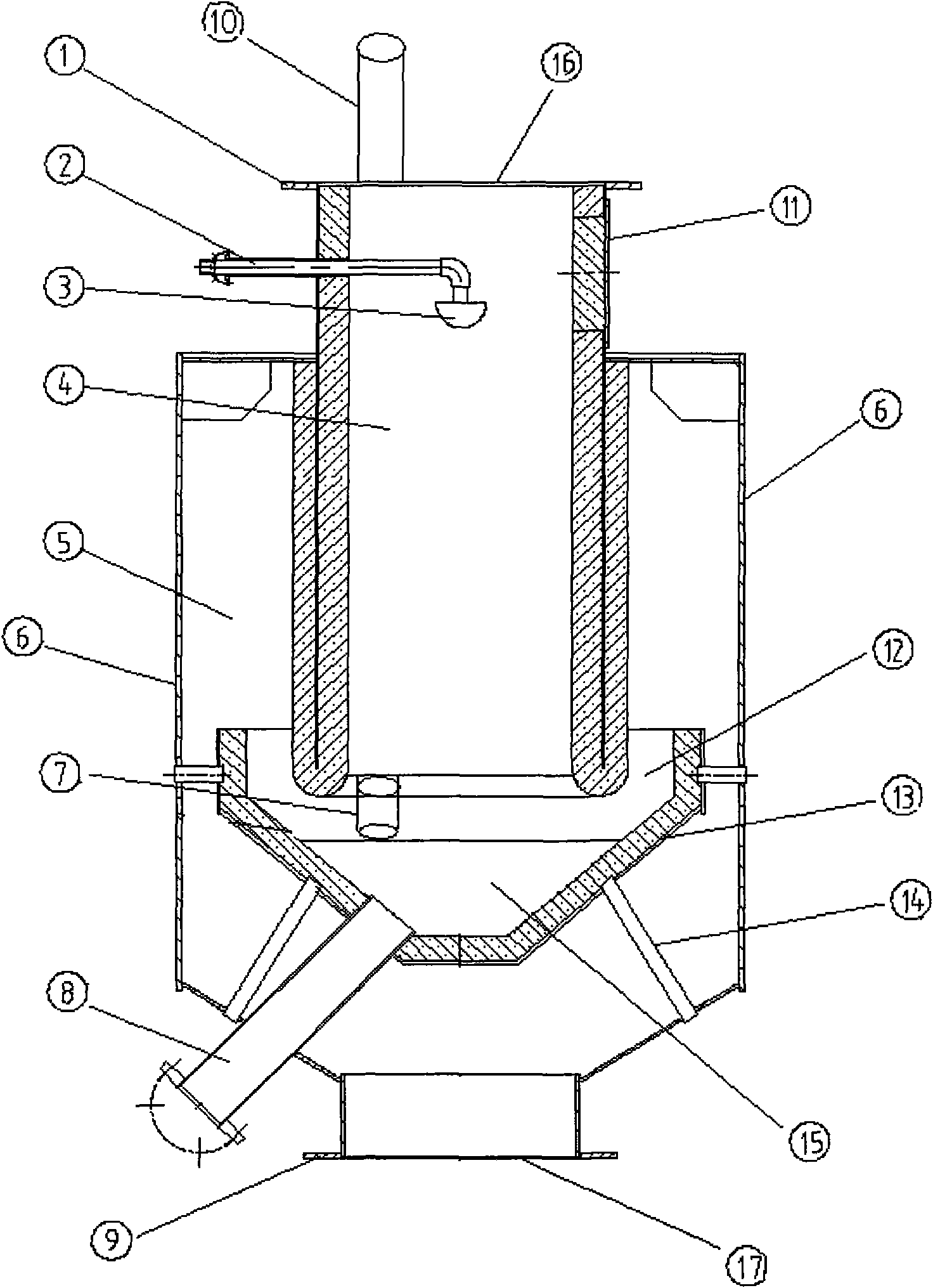

[0010] Roll into a round smoke chamber (5) with a plate rolling machine, with blocking covers (16), (17) welded up and down, two flanges up and down, the upper flange (1) is connected with the chimney (10), and the lower flange ( 9) It is connected to the upper flange (1) of the boiler, the water inlet pipe (2) is connected to the water pump, and the water from the sprinkler head (3) is input into the spray chamber (4) to mix with the flue gas. There is a certain weight afterward, flows out from sewage pipe (7) and falls into settling tank (12) for purification, flows into sewage pond (15) after purification, and flows out through blowdown pipe (8). The sewage pool (15) and the smoke chamber (5) are positioned with the same length round steel (6), so that the sewage pool (15) is concentric with the spray chamber (4), and the sewage pool (15) is supported with a round steel support (14) to ensure The stability of the vertical boiler spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com