Fabric coating slurry and preparing method thereof

A technology for coating pulp and fabrics, which is applied in textiles, papermaking, and fiber treatment, etc. It can solve the problems of poor oil resistance and water resistance, poor light stability and thermal stability, and small contact angle of the film to achieve oil resistance. And the effect of excellent water resistance, good fullness and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

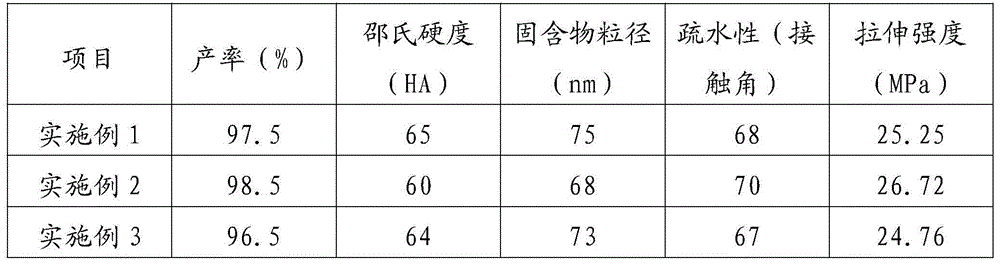

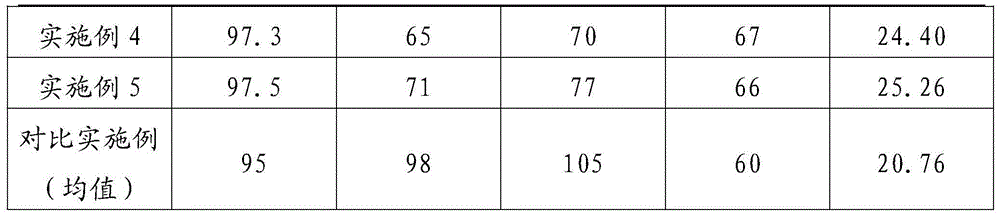

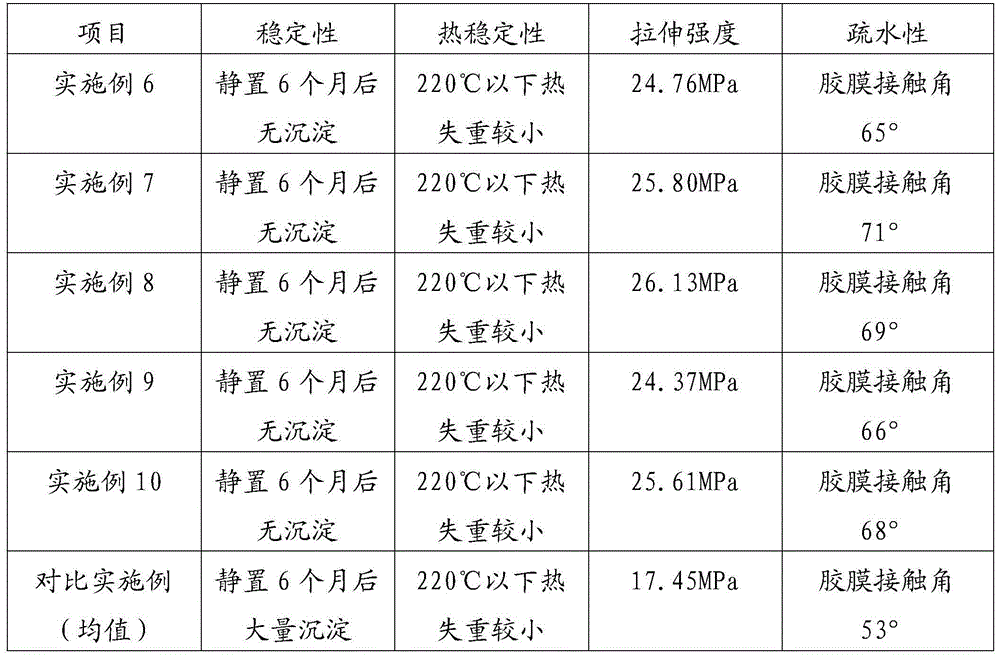

Examples

Embodiment 1

[0030] It adopts the following method to prepare epoxy soybean oil modified waterborne polyurethane:

[0031] First, add epoxidized soybean oil, diethanolamine and isopropanol into the reactor, raise the temperature to 75°C, add tetrafluoroboric acid catalyst, and keep it warm for 20 hours. Oxygenated soybean oil polyol, wherein the diethanolamine quality is 70% of the epoxy soybean oil quality; the isopropanol is 200% of the epoxy soybean oil quality; and the tetrafluoroboric acid is 5% of the epoxy soybean oil quality ;

[0032] Then, under the protection of nitrogen, the obtained epoxidized soybean oil polyol and polyoxypropylene diol, dicyclohexylmethane diisocyanate are added to the reactor, and the polyoxypropylene diol is the quality of epoxy soybean oil polyol 10%, the dicyclohexylmethane diisocyanate is 5% of epoxy soybean oil polyol quality; be warming up to 85 ℃, add organic bismuth catalyst MB20 and T-12, organic bismuth catalyst MB20 and T-12 are epoxy 1% of soy...

Embodiment 2

[0036] It adopts the following method to prepare epoxy soybean oil modified waterborne polyurethane:

[0037] First, add epoxidized soybean oil, diethanolamine and isopropanol into the reactor, raise the temperature to 77°C, add tetrafluoroboric acid catalyst, and keep it warm for 24 hours. Oxygenated soybean oil polyol, wherein the diethanolamine quality is 85% of the epoxy soybean oil quality; the isopropanol is 225% of the epoxy soybean oil quality; and the tetrafluoroboric acid is 5% of the epoxy soybean oil quality ;

[0038]Then, under the protection of nitrogen, the obtained epoxidized soybean oil polyol and polyoxypropylene diol, dicyclohexylmethane diisocyanate are added to the reactor, and the polyoxypropylene diol is the quality of epoxy soybean oil polyol 13%, the dicyclohexylmethane diisocyanate is 6% of epoxy soybean oil polyol quality; be warming up to 87 ℃, add organic bismuth catalyst MB20 and T-12, organic bismuth catalyst MB20 and T-12 are epoxy 2% of soyb...

Embodiment 3

[0042] It adopts the following method to prepare epoxy soybean oil modified waterborne polyurethane:

[0043] First, add epoxidized soybean oil, diethanolamine and isopropanol into the reactor, raise the temperature to 80°C, add tetrafluoroboric acid catalyst, and keep it warm for 28 hours. Oxygenated soybean oil polyol, wherein the diethanolamine quality is 100% of the epoxy soybean oil quality; the isopropanol is 250% of the epoxy soybean oil quality; and the tetrafluoroboric acid is 5% of the epoxy soybean oil quality ;

[0044] Then, under the protection of nitrogen, the obtained epoxidized soybean oil polyol and polyoxypropylene diol, dicyclohexylmethane diisocyanate are added to the reactor, and the polyoxypropylene diol is the quality of epoxy soybean oil polyol 15%, the dicyclohexylmethane diisocyanate is 7% of epoxy soybean oil polyol quality; be warming up to 90 ℃, add organic bismuth catalyst MB20 and T-12, organic bismuth catalyst MB20 and T-12 are epoxy 3% of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com