Modified acrylamide polymer fracturing fluid

An acrylamide and polymer technology, applied in the field of modified acrylamide polymer fracturing fluids, can solve the problems of poor salt resistance, high viscosity, and large limitations, and achieve low damage, moderate crosslinking time, and wide Applicable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

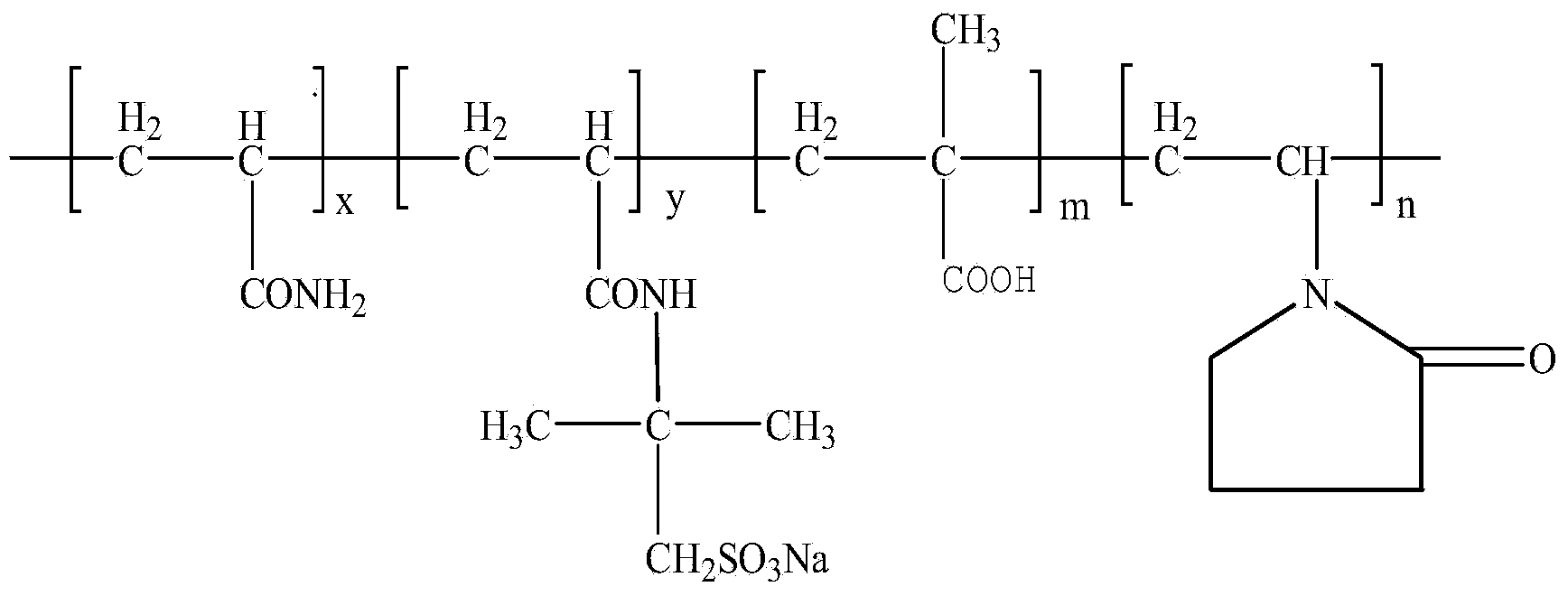

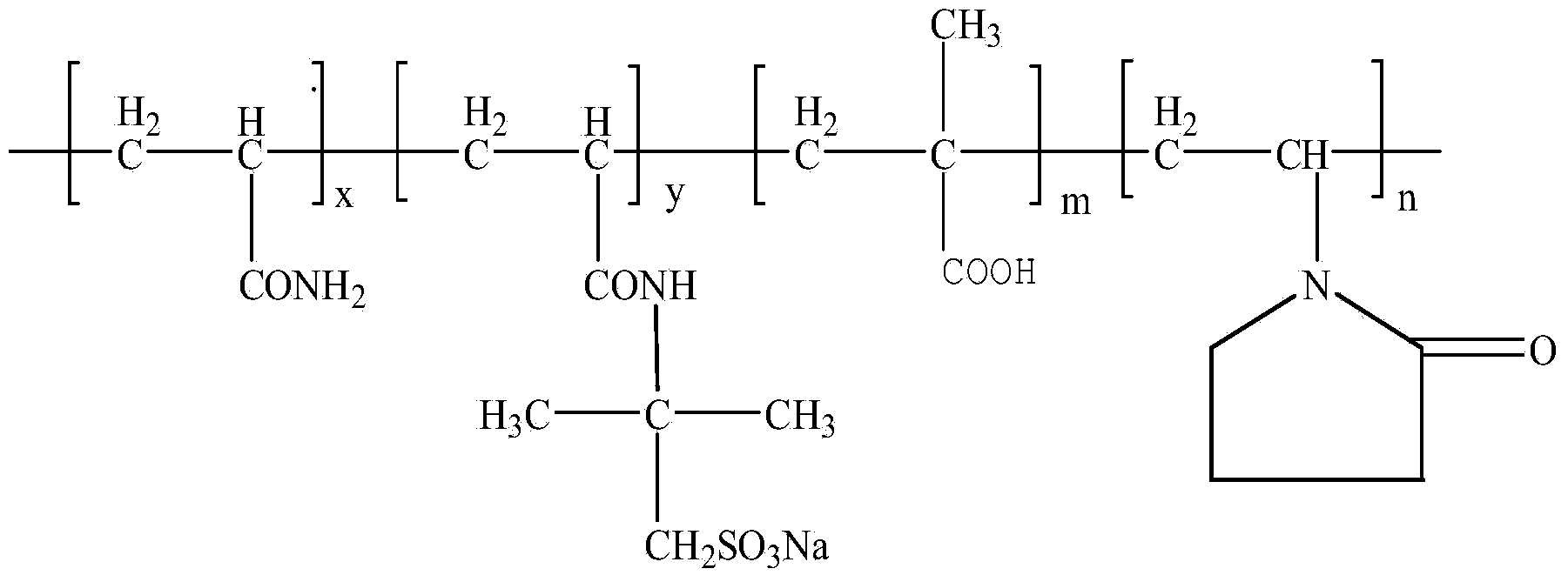

[0022] Add 250 parts of deionized water in parts by mass into a reactor with a stirrer and a thermometer, start stirring and add 10 parts of 2-acrylamido-2-methylpropyl sodium sulfonate, 40 parts of acrylamide, 6 parts Acrylic acid and 4 parts of vinylpyrrolidone were stirred until completely dissolved, and the pH value of the reaction solution was adjusted to 6.5 with 30% aqueous sodium hydroxide solution, heated to 45°C, and nitrogen gas was passed for 20 to 40 minutes until the oxygen was completely removed, and then rapidly to Add 0.2 part of ammonium persulfate, 0.1 part of sodium bisulfite and 0.1 part of azobisisobutylimidazoline hydrochloride initiator into the reaction system, stop stirring after stirring evenly, keep the temperature for 6 hours, and after the reaction finishes, Cut into granules, dry and pulverize to obtain the modified acrylamide polymer thickener A, whose molecular formula is:

[0023]

[0024] Among them, x is 66.67%, y is 16.67%, m is 10%, and...

preparation example 2

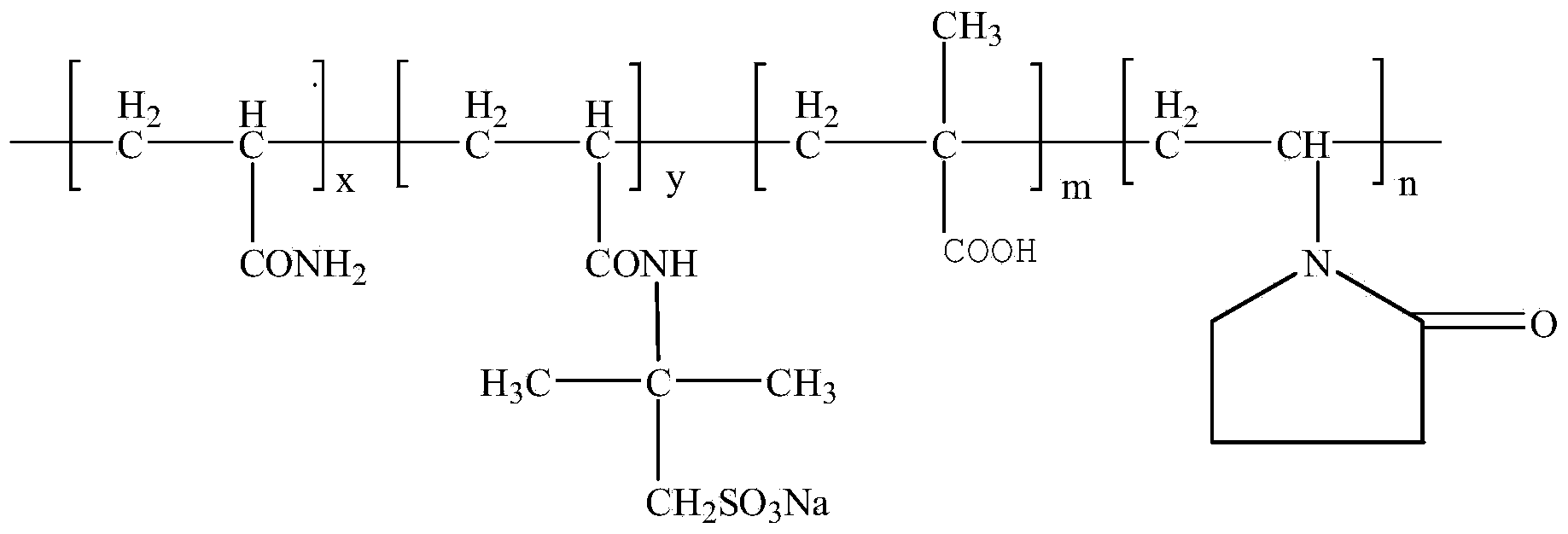

[0026] Add 300 parts of deionized water in parts by mass into a reactor with a stirrer and a thermometer, start stirring and add 12 parts of 2-acrylamido-2-methylpropyl sodium sulfonate, 50 parts of acrylamide, 8 parts α-methacrylic acid, 5 parts of vinylpyrrolidone, stir until completely dissolved, adjust the pH value of the reaction solution to 6 with a 20% aqueous sodium hydroxide solution by mass fraction, raise the temperature to 40°C, and pass nitrogen gas for 20 to 40 minutes until the oxygen is removed As much as possible, quickly add 0.2 parts of potassium persulfate, 0.1 parts of sodium bisulfite and 0.1 parts of azobisisobutylimidyl hydrochloride initiator to the reaction system, stir evenly, stop stirring, keep warm for 8 hours, and after the reaction , after shearing granulation, drying and crushing, the modified acrylamide polymer thickener B is obtained, and its molecular formula is:

[0027]

[0028] Among them, x is 66.67%, y is 16%, m is 10.67%, and n is 6...

Embodiment 1

[0030] First, add 2.25g of modified acrylamide polymer thickener A into a Wuyin mixer filled with 500mL of water, stir until uniform, swell for several hours and set aside. Take out 88.5g of the above-mentioned modified acrylamide polymer thickener and pour it into a 200mL beaker, and add 0.3mL of potassium perfluorononanoate, 1227 and sodium dodecylsulfonate in a ratio of 0.1:1:5 and mix it in turn. Surfactant and 0.5mL glycidyltrimethylammonium chloride clay stabilizer, adjust the pH value of the base solution to 6.5 with acetic acid. Finally, add 0.35 mL of a cross-linking agent mixed with triethanolamine zirconium lactate and tetrabutoxy zirconate in a ratio of 3:1 to the base liquid, and stir with a glass rod to obtain a modified acrylamide Polymer fracturing fluid.

[0031] The crosslinking time of this polymer fracturing fluid is 120s. The viscosity of the fracturing fluid was 251.4 mPa·s after shearing at 120 °C for 90 min using an RS6000 rheometer, and remained at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com