An edible film with continuous anti-oxidation function and its preparation method and application

An edible film, anti-oxidation technology, applied in sustainable manufacturing/processing, climate change adaptation, climate sustainability, etc., can solve the problems of film mechanical properties and barrier properties, etc., to improve water permeability, mild conditions, improve The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

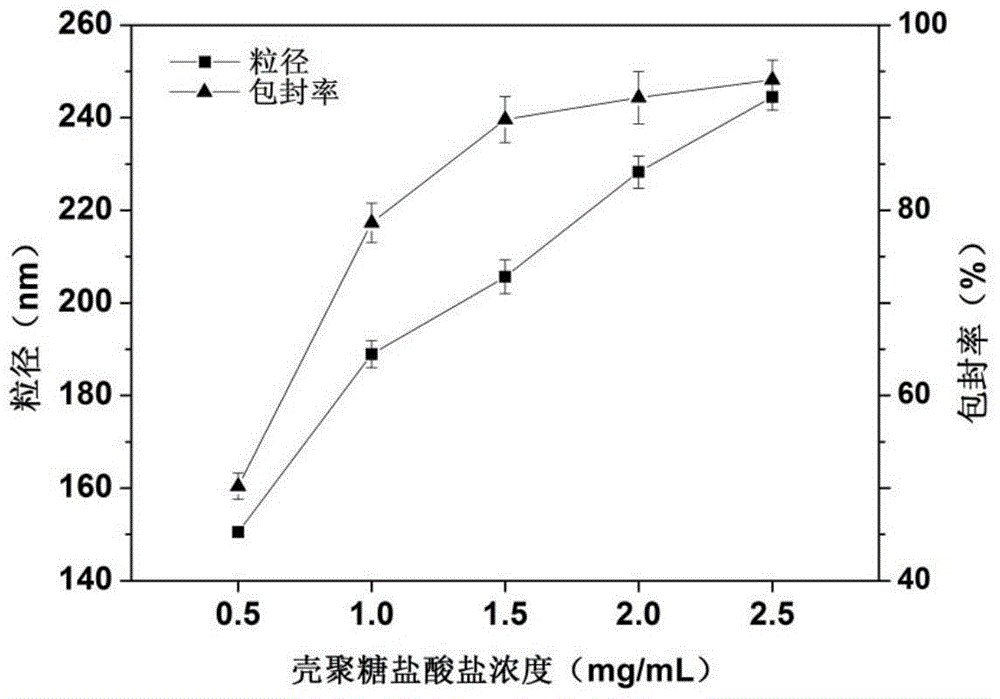

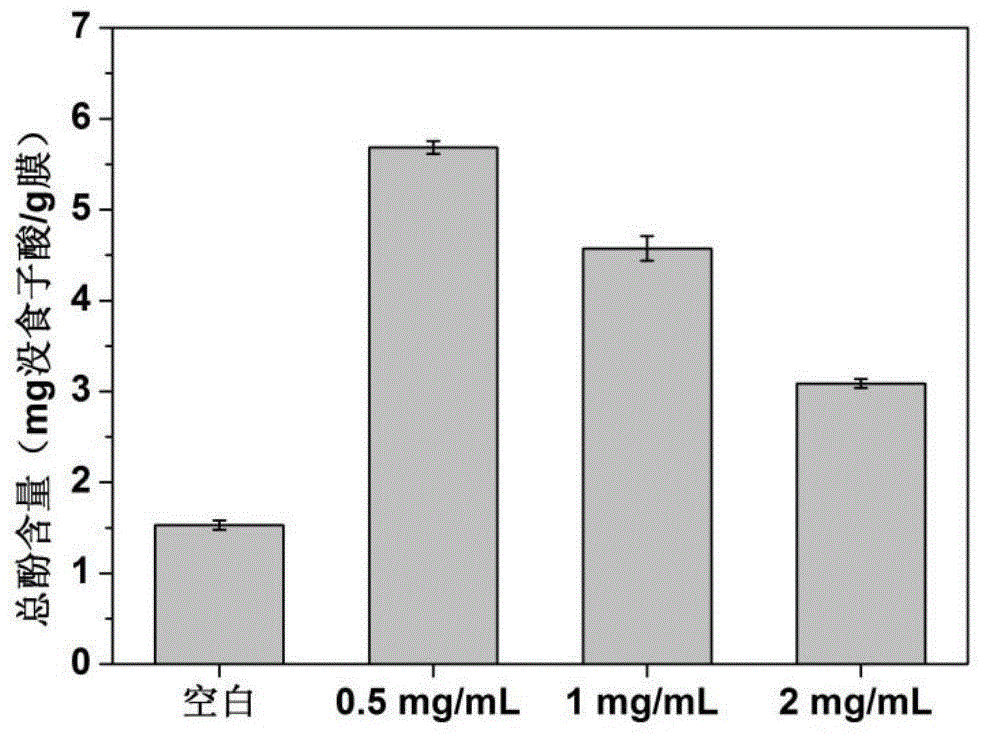

[0027] In this embodiment, an edible film with sustained anti-oxidation function is provided, which includes, by mass percentage, 0.5-5% tea polyphenols, 1%-10% chitosan hydrochloride, 1.5 %~15% of sulfobutyl-β-cyclodextrin, and the rest is a natural edible biomacromolecule film-forming matrix, and the edible film is chitosan hydrochloride with different encapsulation rates and sizes of tea polyphenols Nanoparticles are added to the natural edible biomacromolecule film-forming matrix; wherein, the natural edible biomacromolecule film-forming matrix is starch, chitosan, modified cellulose, carrageenan, pectin, tara gum One or more of sodium alginate, pullulan, whey protein, soy protein isolate, zein and wheat gluten.

[0028] A kind of preparation method of described edible film with continuous antioxidant function, its steps are:

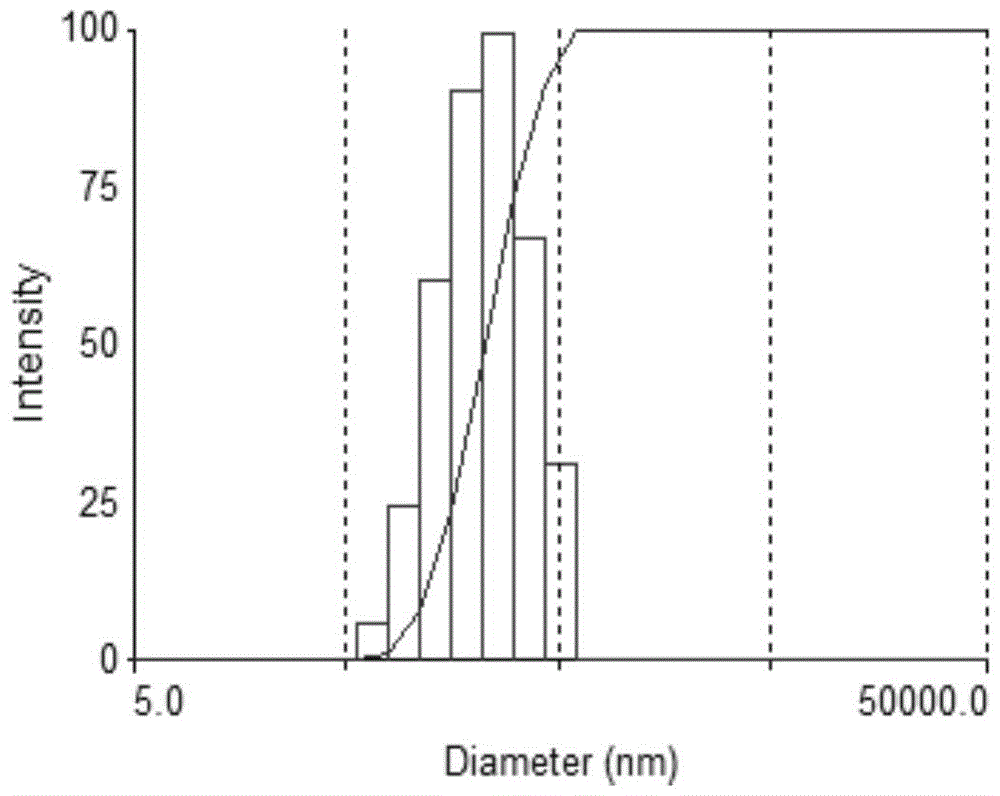

[0029] (1) Preparation of chitosan hydrochloride nanoparticles with different tea polyphenol encapsulation efficiency and particle size:

[003...

Embodiment 2

[0036] (1) The preparation of chitosan hydrochloride nanoparticles with different tea polyphenol encapsulation efficiency and particle size is the same as in Example 1.

[0037] (2) Preparation of film-forming solution: after a certain amount of tara gum (mass concentration 2%) was stirred and dissolved at 35° C., glycerin was added as a plasticizer according to the mass ratio of 25% (tara gum). Mix 75 mL of nanoparticles prepared in step (1) with 25 mL of tara gum film-forming matrix solution, stir evenly, and centrifuge to degas.

[0038] (3) Preparation of film: Take a certain volume of the film-forming solution prepared in step (2) and pour it into a mold (10×10cm), dry it at 35°C for 24 hours, and place it in a constant temperature and humidity box (temperature 25°C, relative humidity 53 %) for at least 48 hours to obtain an edible film with sustained antioxidant function.

Embodiment 3

[0040] (1) The preparation of chitosan hydrochloride nanoparticles with different tea polyphenol encapsulation efficiency and particle size is the same as in Example 1.

[0041] (2) Preparation of film-forming solution: a certain amount of whey protein (mass concentration 6%) was stirred and dissolved at 80° C., cooled to room temperature, and glycerol was added as a plasticizer in a proportion of 30% (whey protein). Mix 75 mL of nanoparticles prepared in step (1) with 25 mL of whey protein film-forming matrix solution, stir evenly, and vacuum degas.

[0042] (3) Preparation of film: Take a certain volume of the film-forming solution prepared in step (2) and pour it into a mold (10×10cm), dry it at 30°C for 36h, and place it in a constant temperature and humidity box (temperature 25°C, relative humidity 53 %) for at least 48 hours to obtain an edible film with sustained antioxidant function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com