A device for applying a glue track to a covering strip of a rod-shaped product in the tobacco processing industry

A technology of processing industry and glue, applied in the direction of tobacco, application, manufacture of cigarettes, etc., can solve the problem of high cost and achieve the effect of reducing the penetration of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

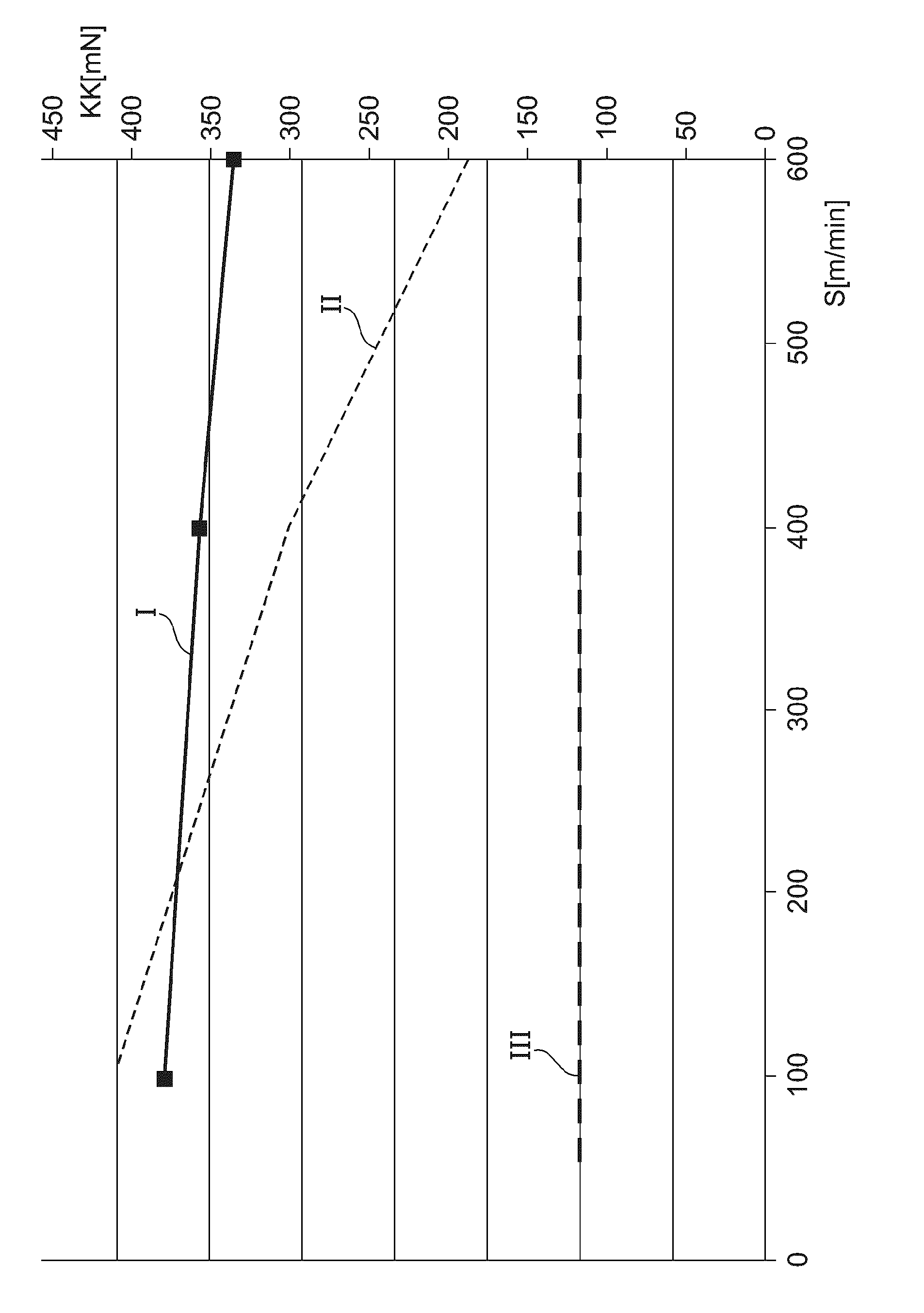

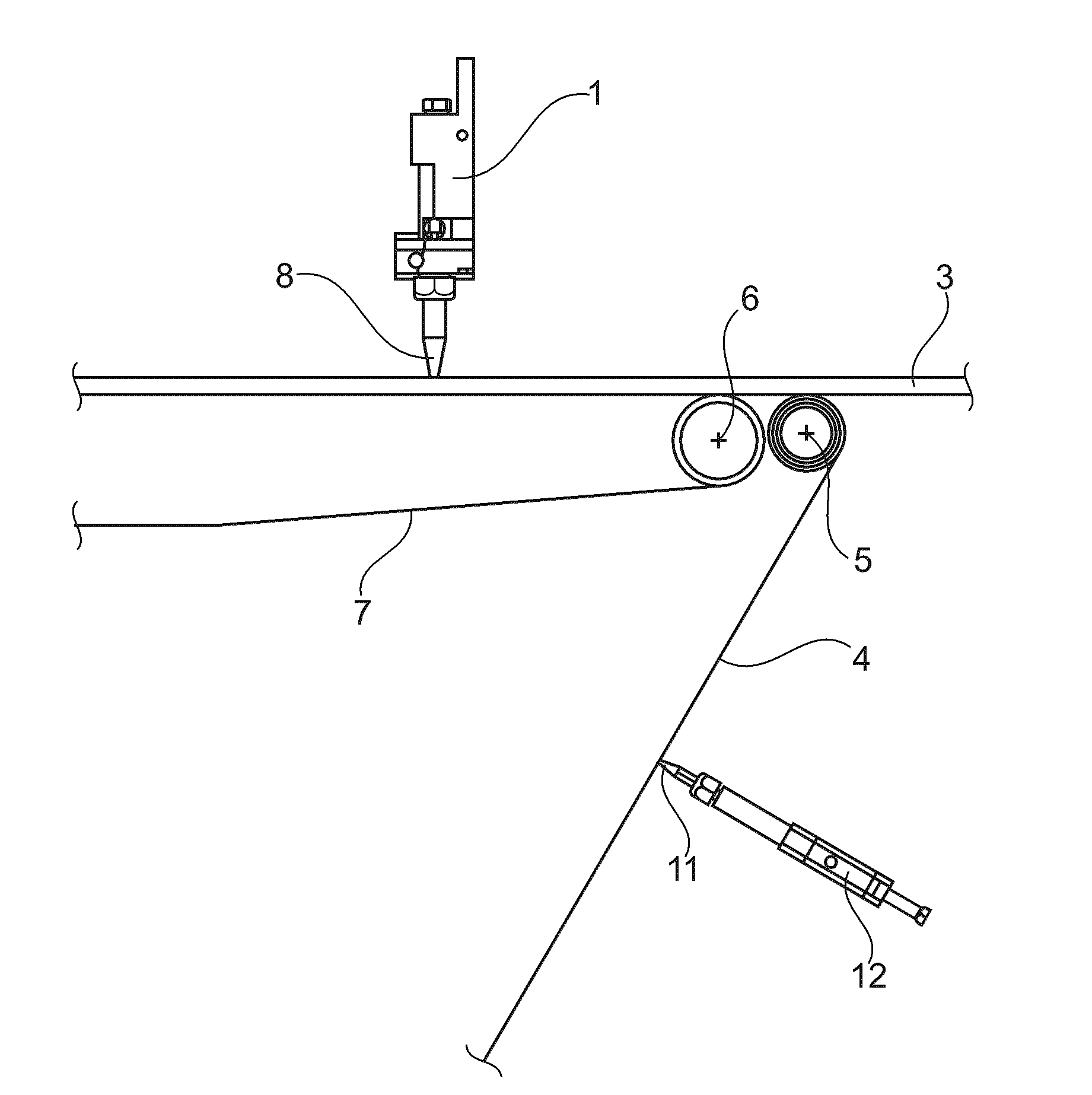

[0028] exist figure 1 The device according to the invention for gluing the moving coating strip 4 with the nozzle 8 of the coating device 1 can be seen in . The covering strip 4 is, for example, a continuous strip of cigarette paper or filter paper, which is fed from below in the familiar manner and is laid down by means of a deflection mechanism 5 onto a likewise continuous bong band 7 . Simultaneously, the continuous tobacco or filter material fiber strip 3 is laid down onto the deflected wrapping strip 4 from above. The bong belt 7 is guided via the second deflection mechanism 6 onto the bong base (Format Grund) and is used for transporting the covering strip 4 together with the laid on during the further movement on the bong base Tobacco or filter material fiber strip 3. The bong base itself, including the covering strip (not shown) arranged thereon, is provided with a profile, by means of which overall a shaping channel is formed, through which the covering strip is cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com