Multifunctional structure and method for its manufacture

A multifunctional and functional technology, applied in the field of manufacturing such structures, multi-layer flexible structures, can solve the problem of microbeads not being able to expand, and achieve the effect of thermal insulation and/or sound insulation and/or electromagnetic shielding of buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

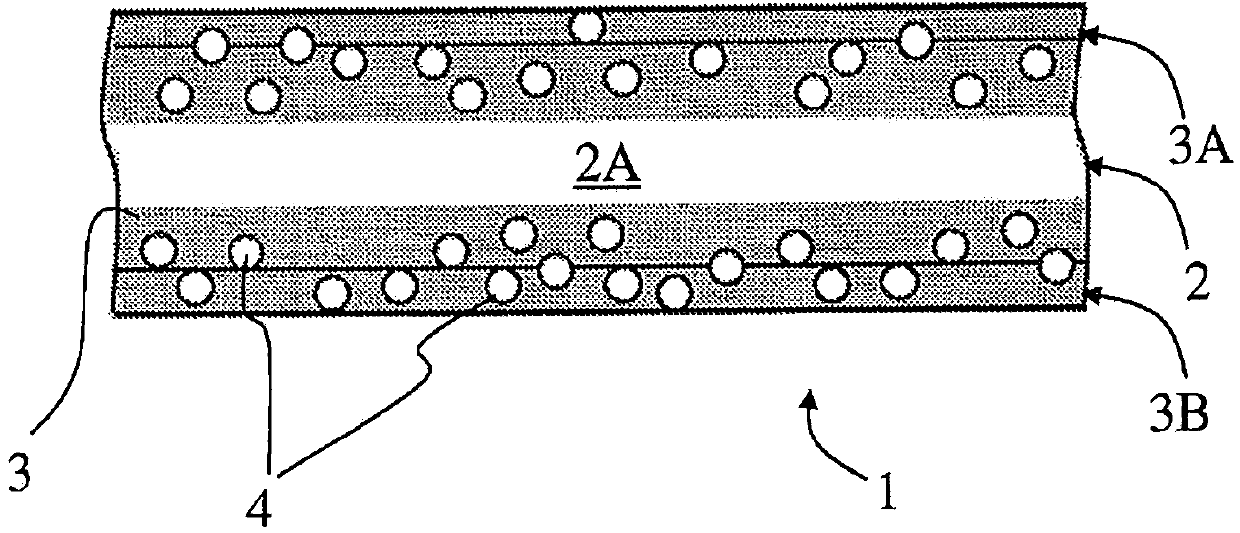

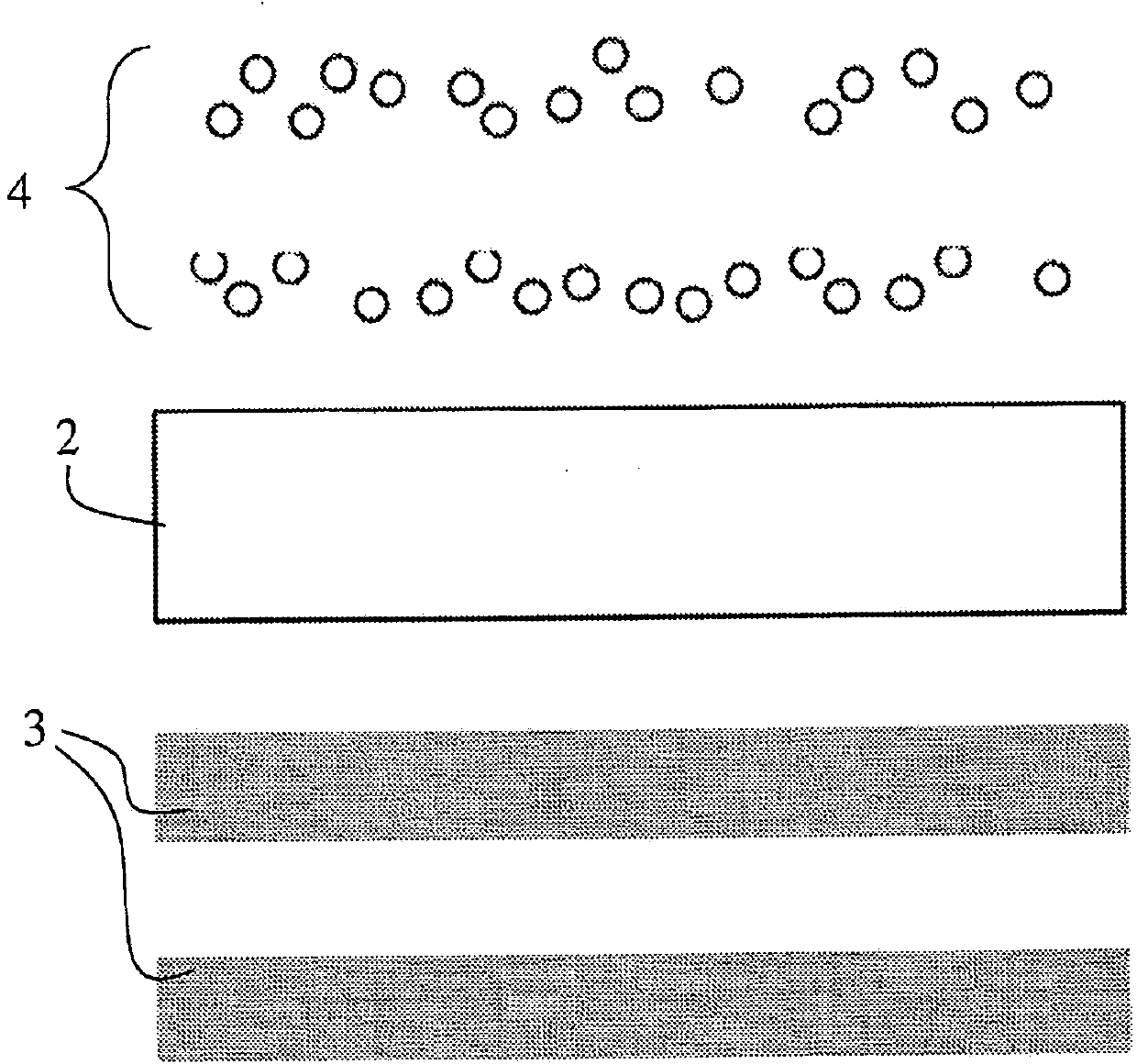

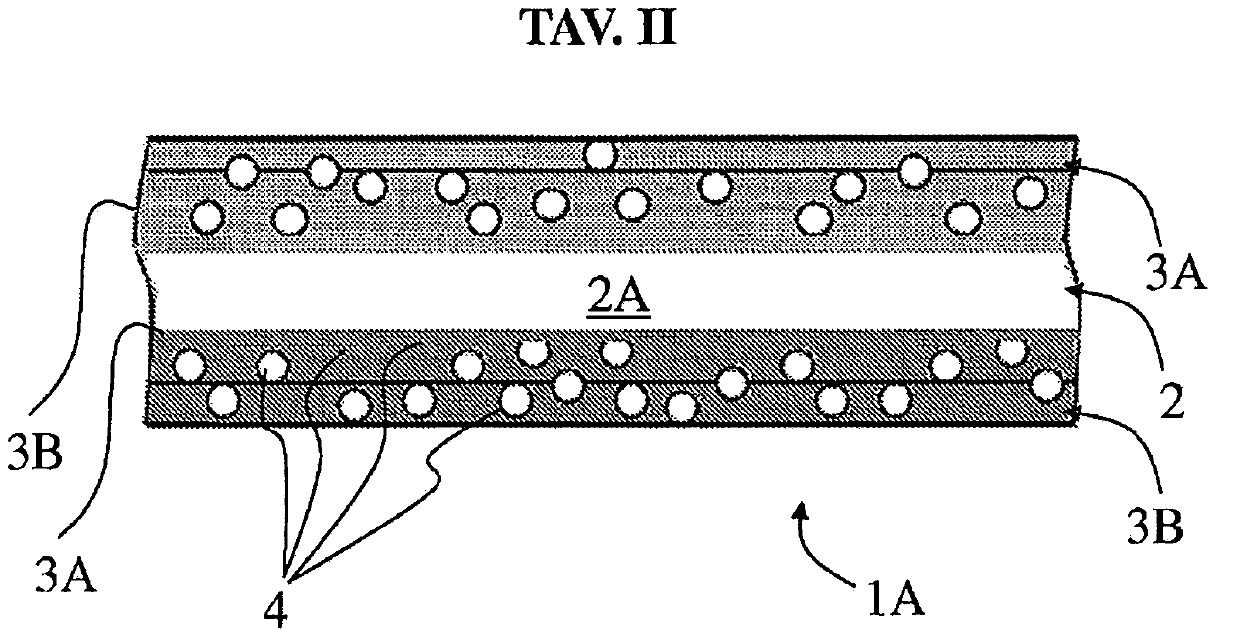

[0189] The structure of the present invention is used to provide a system for renovating cosmetic or masonry structures damaged by cracks, fissures, local peeling or peeling of paint or plaster, while also providing good thermal and / or acoustic insulation, due to the combination with Compared with the prior art, the present invention can simultaneously:

[0190] a. Limiting or inhibiting the transfer of deformation from the inner surface to the outer surface, where the inner surface is in contact with the masonry structure when the application is performed on it, and the outer surface is the surface on which the finish can subsequently be made, by means of the resin layer Extensibility to provide the unimpregnated inner layer of the fibrous support that functions as a variable interposition device,

[0191] b. Provide thermal insulation functionalization due to the higher void level of the resin obtained by expansion of the hollow filler by providing an unimpregnated inner lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com